Laminate, and method for producing light-emitting diode provided with wavelength conversion layer

A technology of laminates and phosphors, used in chemical instruments and methods, coatings, layered products, etc., can solve problems such as limited luminous color, achieve uniform film thickness, easy peeling, and prevent damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0121] Using a polyethylene container with a volume of 300ml, "OE-6630A / B" (manufactured by TORAY-DOW CORNING Co., Ltd., refractive index: 1.53) as a silicone resin and "NYAG-02" ( Manufactured by Intematix: Ce-doped YAG phosphor, specific gravity: 4.8g / cm 3 , D50:7 μm) were mixed at a ratio of 40.0% by mass of OE-6630A / B and 60.0% by mass of NYAG-02.

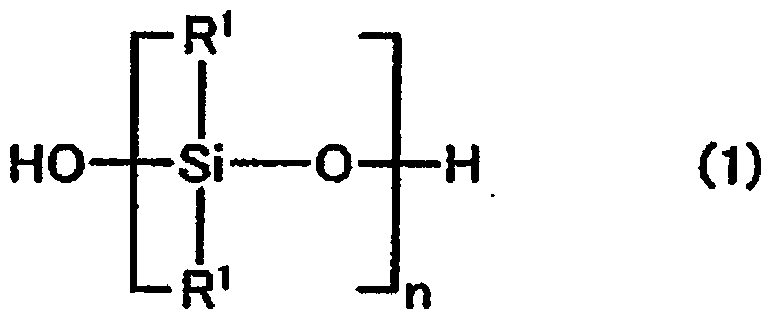

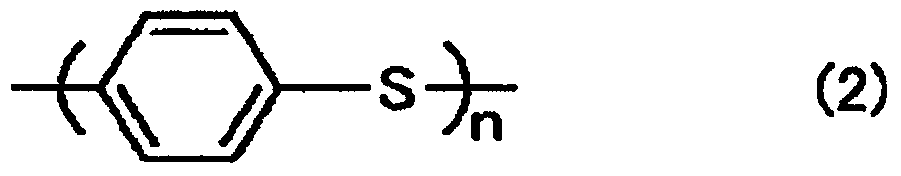

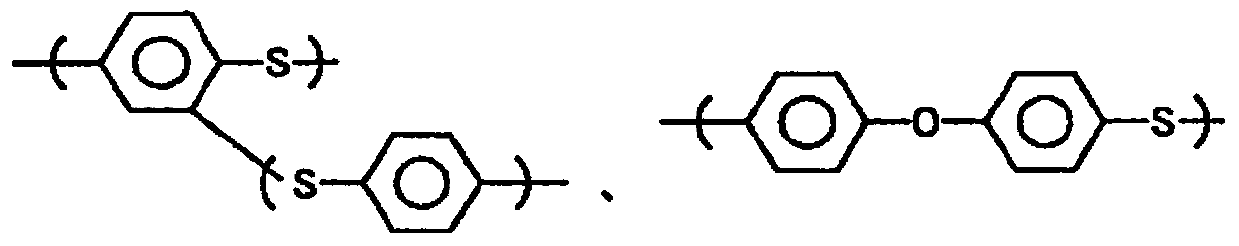

[0122] Then, stirring and defoaming were performed at 1000 rpm for 20 minutes using a planetary stirring and defoaming device "Mazerustar (registered trademark)" KK-400 (manufactured by Kurabo), to obtain a phosphor sheet preparation liquid. Using a slit coater, the resin solution for sheet production was coated on the polyphenylene sulfide film "TORELINA (registered trademark)" (manufactured by Toray Co., Ltd.), heated and dried at 130°C for 2 hours, A laminate in which a phosphor sheet having an average film thickness of about 100 μm was formed was obtained. In the obtained laminate, the phosphor sheet was uniformly applied...

Embodiment 2~ Embodiment 4

[0129] Silicone microparticles 1 were added to make the amount listed in Table 1, and the amount of each component was adjusted so that the content of the phosphor particles in the phosphor sheet was kept at 60.0% by mass. In the same manner as in Example 1, except that Fabricate phosphor sheets. "SD4580" (silicon adhesive manufactured by Toray Dow Corning Co., Ltd.) was coated on the phosphor sheet, and heated and dried at 100° C. for 15 minutes to obtain an adhesive layer.

[0130] On the adhesive layer, "Cerapeel (registered trademark)" BLK (manufactured by Toray Film Processing Co., Ltd.)" was laminated as a cover film at room temperature.

[0131] Next, in order to test the substrate peelability of the obtained laminated body, transfer lamination was performed on the glass substrate.

[0132]The laminated body was cut into 100 mm x 50 mm, and the cover film was peeled off. Next, the surface where the adhesive layer was peeled off and the adhesive layer was exposed was b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com