Preparation method of anti-biological-pollution PVDF (polyvinylidene fluoride) film

A technology of polyvinylidene fluoride film and polyvinylidene fluoride, which is applied in the field of polymer film modification, can solve problems such as negligence, increase surface energy, improve pure water flux and antibacterial properties, and controllable modification conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

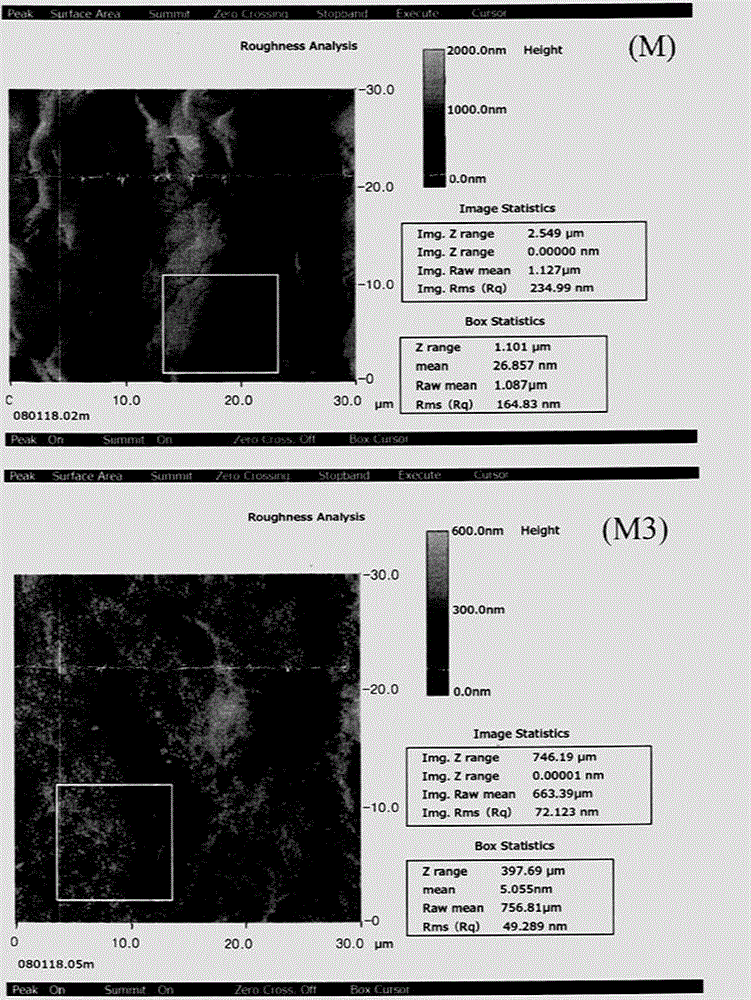

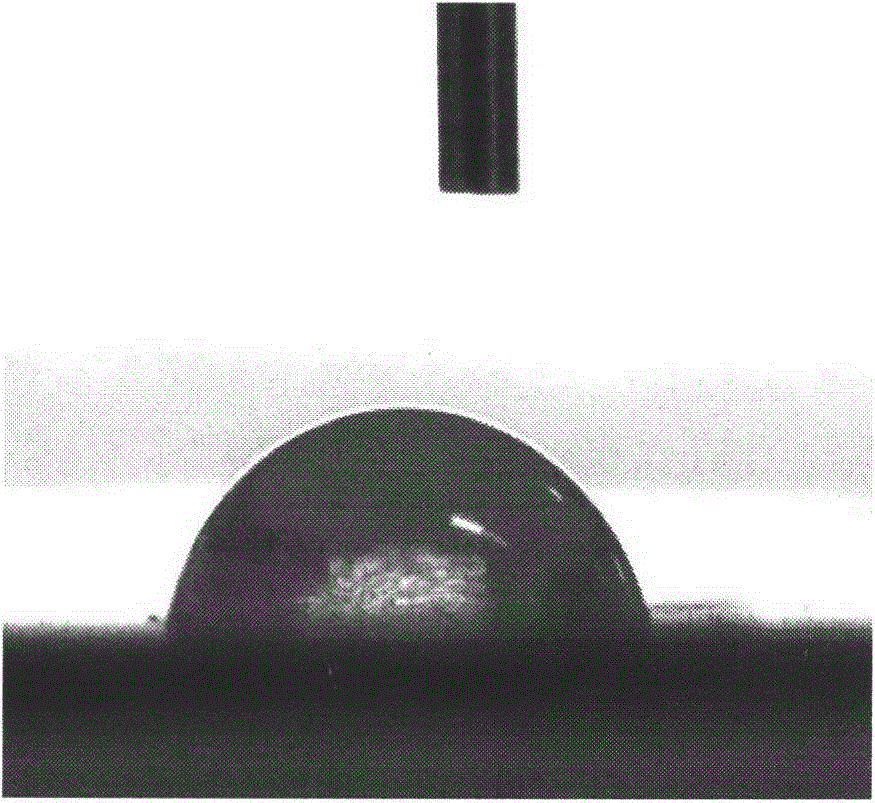

[0033] Dissolve 1.0 g of polyvinylpyrrolidone (PVP) and 9.0 g of PVDF in 40 g of N,N-dimethylacetamide (DMAc), and stir continuously in a water bath at 65°C for 24 hours to obtain a PVDF casting solution, which is sealed and statically Degassing for 2 days. Use a self-made scraper to control the amount of liquid on a clean glass plate at room temperature to scrape the film, stay in the air for about 30 seconds, quickly immerse it in a water coagulation bath, and change the water repeatedly to remove the solvent and porogen to make the PVDF film (M). Its characteristics: the PVDF casting membrane solution is prepared with the best ratio of each component, and the separation membrane obtained from this has better performance in various aspects.

Embodiment 2

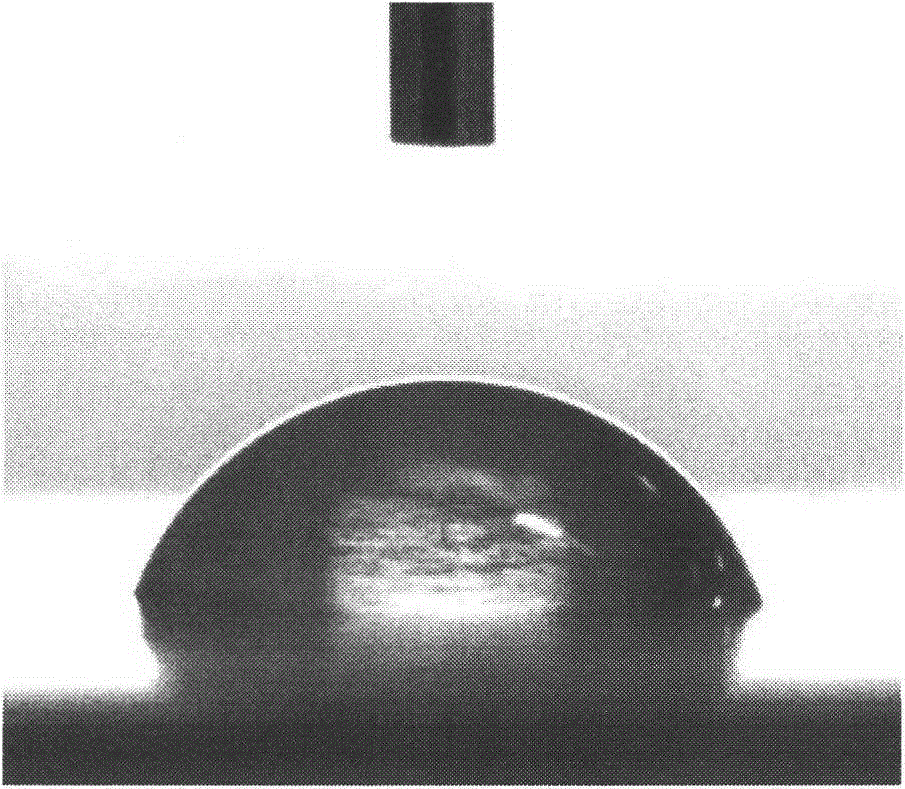

[0035] Ultrasonic dispersion of 0.5 g of nano-silver phosphate in 39.5 g of N,N-dimethylacetamide (DMAC) for 2 hours, followed by adding 9.0 g of PVDF and 1.0 g of polyvinylpyrrolidone (PVP), and continuously stirring in a water bath at 65°C for 24 Hour obtains the PVDF casting solution containing silver phosphate, and it is sealed and left to stand for 2 days for degassing. Use a self-made scraper to control the amount of liquid on a clean glass plate at room temperature to scrape the film, stay in the air for about 30 seconds, quickly dip into the water coagulation bath, change the water repeatedly to remove the solvent and porogen, and make the modified PVDF membrane (M1).

Embodiment 3

[0037]Ultrasonically disperse 0.5 g of negative ion powder in 39.5 g of N,N-dimethylacetamide (DMAC) for 2 hours, add 9.0 g of PVDF and 1.0 g of polyvinylpyrrolidone (PVP) in sequence, and continuously stir in a water bath at 65°C for 24 hours Obtain silver phosphate-containing PVDF casting solution, which is sealed and allowed to stand for 2 days for degassing. Use a self-made scraper to control the amount of liquid on a clean glass plate at room temperature to scrape the film, stay in the air for about 30 seconds, quickly immerse in a water coagulation bath, change the water repeatedly to remove the solvent and porogen, and make the modified PVDF membrane (M2).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com