Method for producing chemical raw materials by comprehensively utilizing manganese slag

A technology of chemical raw materials and manganese slag, applied in the direction of silicon oxide, manganese sulfate, silicon dioxide, etc., can solve the problems of waste of available resources, secondary pollution of the environment, etc., and achieve the effect of reducing secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

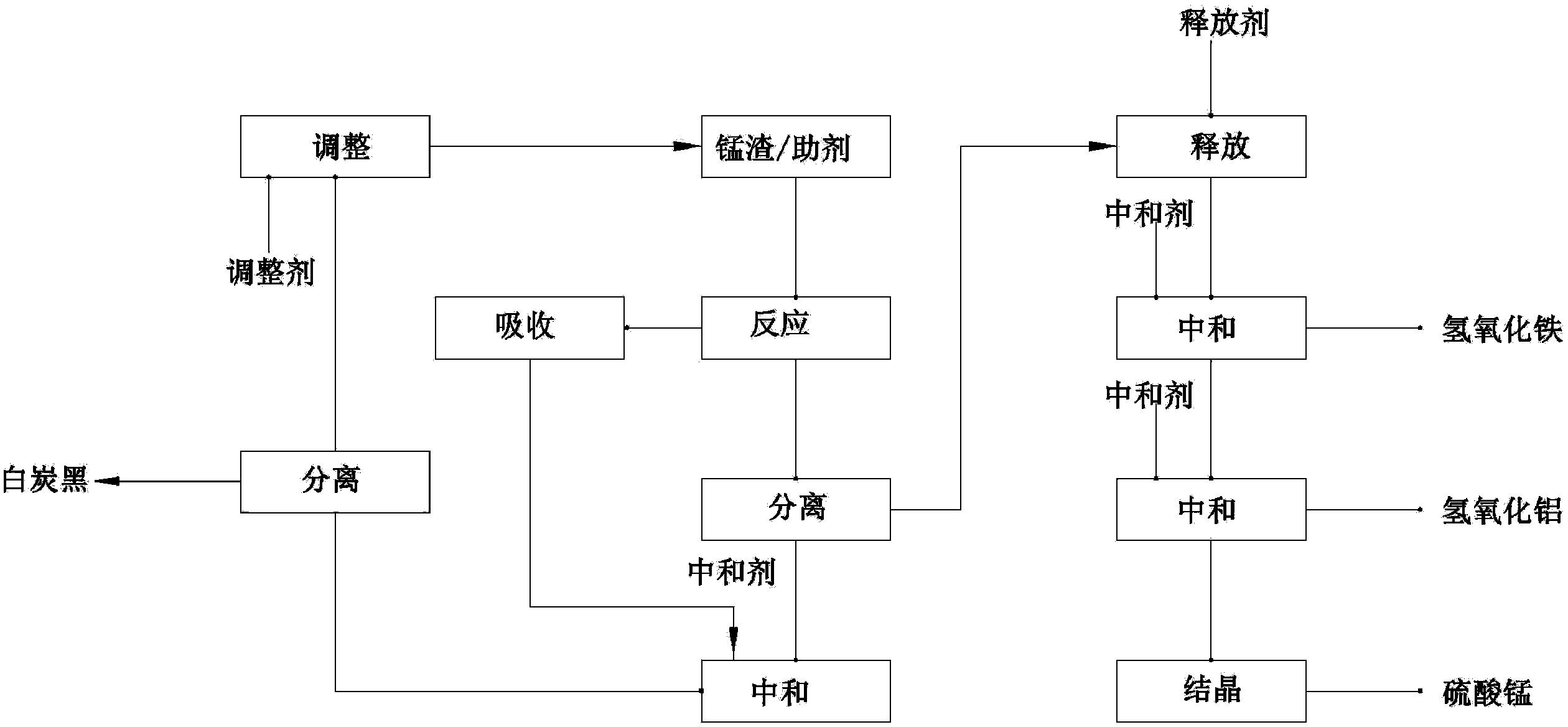

[0025] refer to figure 1 , the method for the comprehensive utilization of manganese slag described in the present embodiment to produce chemical raw materials, comprises the following steps:

[0026] 1. Reaction: first crush the manganese slag to 80 mesh, then mix it with ammonium fluoride solution with a concentration of 10%, place it in the main reactor and heat it for 0.5 hours, and the reaction temperature is 80°C; the manganese slag and fluoride The ammonium solution is mixed in a ratio of 1:8 according to the mass volume ratio; after the reaction, solid-liquid separation is obtained to obtain solid A and liquid A;

[0027] 2. Absorption: the gas generated in the reaction process described in step 1 is absorbed through a tube-and-tube heat exchanger to obtain liquid B;

[0028] 3. Neutralization: Mix liquid A, liquid B and sodium hydroxide solution according to the mass volume ratio of 1:0.5:0.1, and react fully at 50°C to obtain a white carbon black suspension; solid-...

Embodiment 2

[0032] refer to figure 1 , the method for the comprehensive utilization of manganese slag described in the present embodiment to produce chemical raw materials, comprises the following steps:

[0033] 1. Reaction: first crush the manganese slag to 150 mesh, then mix it with 20% ammonium fluoride solution, place it in the main reactor and heat it for 1.5 hours at a reaction temperature of 90°C; the manganese slag and fluoride The ammonium solution is mixed according to the mass volume ratio of 1: 4; after the reaction, solid-liquid separation is obtained to obtain solid A and liquid A;

[0034] 2. Absorption: the gas produced in the reaction process described in step 1 is absorbed through a packed absorption tower to obtain liquid B;

[0035] 3. Neutralization: Mix liquid A, liquid B and sodium hydroxide solution according to the mass volume ratio of 1:1:0.5, and react fully at 70°C to obtain a white carbon black suspension; solid-liquid Separation to obtain white carbon bla...

Embodiment 3

[0039] refer to figure 1 , the method for the comprehensive utilization of manganese slag described in the present embodiment to produce chemical raw materials, comprises the following steps:

[0040] 1. Reaction: first crush the manganese slag to 200 mesh, then mix it with a 35% ammonium fluoride solution, place it in the main reactor and heat it for 2.5 hours at a reaction temperature of 110°C; the manganese slag and fluoride The ammonium solution is mixed according to the mass volume ratio of 1: 0.2; solid-liquid separation after the reaction, to obtain solid A and liquid A;

[0041] 2. Absorption: the gas generated in the reaction process described in step 1 is absorbed through a spray absorption tower to obtain liquid B;

[0042] 3. Neutralization: Mix liquid A, liquid B and sodium hydroxide solution according to the mass volume ratio of 1:2:1, and react fully at 90°C to obtain a white carbon black suspension; solid-liquid Separation to obtain white carbon black and li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com