Oil-water separation method and oil-water separation device

An oil-water separation device and oil-water separation technology, which are applied in separation methods, liquid separation, grease/oily substance/floating matter removal devices, etc., can solve problems such as incompleteness, inability to work after power failure, and difficulty in cleaning, and achieve complete oil-water separation. Energy saving and efficient cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

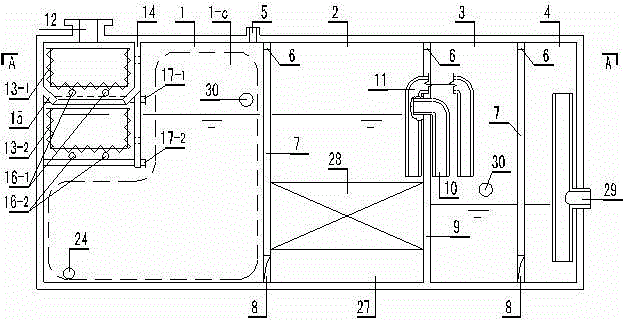

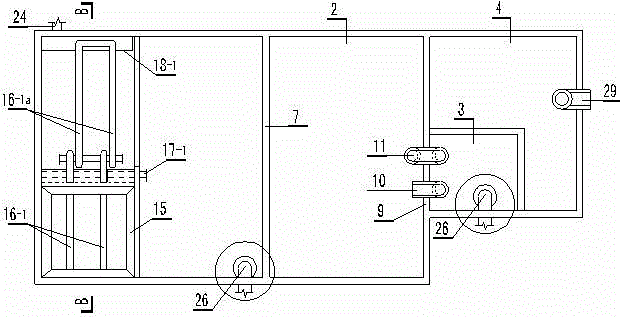

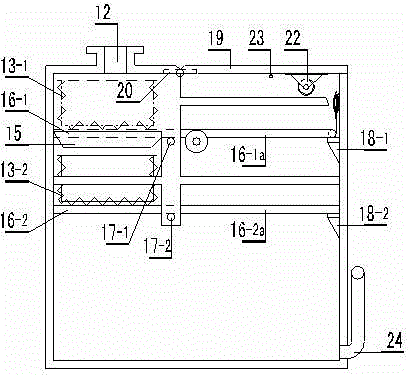

[0048] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0049] see figure 1 , figure 2 , image 3 Shown, a kind of oil-water separation method of the present invention is characterized in that comprising the steps:

[0050] 1) Introduce the oily wastewater into the pretreatment unit including two-stage removable grid slag baskets, and remove coarse and larger substances (solids and particles) through the first-stage grid slag baskets, such as diameter or size greater than 5mm Substances, through the secondary mesh slag basket to intercept and remove broken small slag particles, such as substances with a diameter or size less than 5mm;

[0051] 2) For vegetable oil, pass the pretreated oily wastewater through the primary oil-water separation unit at a flow rate of less than 0.0055m / s and a residence time of more than 25min; for animal oil, pass the pretreated oily wastewater at a flow rate of less than 0.0063m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com