Method for preparing sulodexide raw material from heparin byproduct by adopting ethanol precipitation process

A technology for heparin by-product and ethanol, which is applied in the field of preparing sulodexide raw materials, can solve the problems of short polysaccharide chain length and low degree of sulfation, and achieves the effects of low cost, simple process and easy amplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Dissolve heparin by-products (including CS5%, DS50%, fast heparin 25%, slow heparin 20%, titer 41usp u / mg, specific rotation +15°) into a 10% (m / m) solution, and dissolve in 6M hydrogen Adjust the pH to 11.0 with sodium oxide, add ethanol to a mass concentration of 31%, and precipitate at 2-8°C for 2 hours. Centrifuge at 4000rpm for 30min, collect the supernatant to obtain the sulfated polysaccharide solution after removing slow heparin.

[0019] Add water to the obtained sulfated polysaccharide solution to make the ethanol concentration 24%, adjust the pH to 2.0 with 6M hydrochloric acid, add ethanol until the mass concentration is 40%, and precipitate at 2-8°C for 1-2 hours. The supernatant was collected by centrifugation to obtain a sulfated polysaccharide solution after dermatan sulfate was reduced.

[0020] Add water to the obtained solution to make the ethanol concentration 36%, adjust the pH to 7.0 with 6M sodium hydroxide, add solid NaCl to a mass concentration...

Embodiment 2

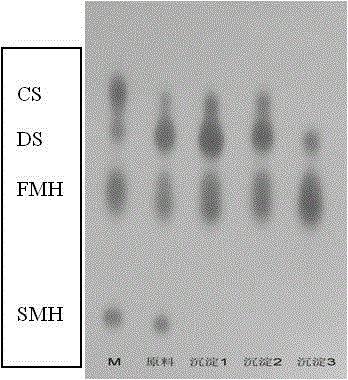

[0023] Take the raw material of Example 1, the product after the first precipitation, the product after the second precipitation, the product after the third precipitation (final product), etc. for agarose gel electrophoresis analysis, the method refers to the patent "a glass-mounted electrophoresis method Method for analyzing mucopolysaccharides 200910040788.8". The result is as figure 1 As shown, M represents the raw material of heparin by-products. The raw material contains CS, DS, fast heparin, and slow heparin. After the first precipitation, the slow heparin was removed. After the second precipitation, the DS content was reduced, and the third precipitation was removed. CS, to obtain the final product: DS 20-30%, fast heparin 70-80%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com