Preparation method of carboxymethylcellulose sodium composite filled polyamide nanofiltration membrane

A technology of sodium carboxymethyl cellulose and composites, which is applied in the field of preparation of polyamide nanofiltration membranes filled with sodium carboxymethyl cellulose composites, which can solve the problems of high manufacturing costs of nanomaterials, ineffective modification effects, and membrane defects. and other issues, to achieve the effect of convenient and easy access to raw materials, good industrial applicability, and excellent membrane performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

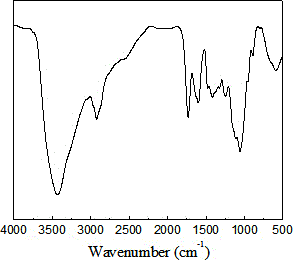

[0017] (1) 1 to 3 mass sodium carboxymethyl cellulose sodium and 0.5 to 2 cationic polycatolences are dissolved in an acidic aqueous solution of 100 to 500 mass, respectively, and then dripping the above -mentioned yang ionsIonic cross -linked in the sodium carboxymethyl cellulose sodium cellulose, removal of ionic water sedimentation after many times, washing and drying obtained sodium carboxymethyl cellulose sodium composite;~ 500 alkaline water solution with mass parts into a complex dispersal liquid;

[0018] (2) Discipline the polyamine monomer in the water, and then add the complex dispersing solution and sodium hydroxide solid to the water phase solution; dissolve the multi -alcohol -chlorine monomer in an organic solvent, and match the organic phase solution;

[0019] (3) Make a porous aggregate supporting film in a water phase solution for 1 to 4 minutes, remove and remove excessive surface water phase solutions; then immerse in the organic phase solution for 0.5 to 2 min...

Embodiment 1

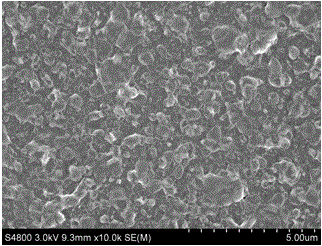

[0024] Sodium carboxymethyl cellulose sodium complexes fill the polyamide nanoferous membrane at 25 o C, 0.6MPa pressure, for 1G.L -1 NaCl and NA 2 So 4 The separation result of the solution is: the interception rate of NACL is 21.2%, and the water flux is 50.6l.m -2 .h -1 ; 2 So 4 The interception rate is 94.7%, and the water flux is 49.5L.M -2 .h -1 Essence

[0025] Example 2:

Embodiment 2

[0027] Sodium carboxymethyl cellulose sodium complexes fill the polyamide nanoferous membrane at 25 o C, 0.6MPa pressure, for 1G.L -1 NaCl and NA 2 So 4 The separation result of the solution is: the interception rate of NACL is 23.5%, and the water flux is 53.8l.m -2 .h -1 ; 2 So 4 The interception rate is 95.2%, and the water flux is 52.5L.M -2 .h -1 Essence

[0028] Example 3:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com