Methanation catalyst and preparation method thereof

A methanation catalyst, catalyst technology, applied in catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve problems such as large environmental impact, complex preparation process, long production cycle, etc., and achieve energy consumption Low, simple process, low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The preparation method of the present embodiment comprises the following steps:

[0028] Step 1, take by weighing 294.3 grams of Al(NO 3 ) 3 9H 2 O, 77.6 g Ni(NO 3 ) 2 ·6H 2 O was dissolved in a small amount of deionized water, 310 g of ethylene glycol was added, mixed evenly, and dried at 80° C. for 5 h until a gel-like product was formed.

[0029] Step 2. Transfer the gel product to a crucible or a quartz boat, put it directly into a muffle furnace with a preset temperature of 500°C, and carry out a combustion reaction for 60 minutes. Take out the solid material after combustion, wash it with deionized water, and dry it. After that, the prepared catalyst is 20%NiO / γ-Al 2 o 3 (ethylene glycol A).

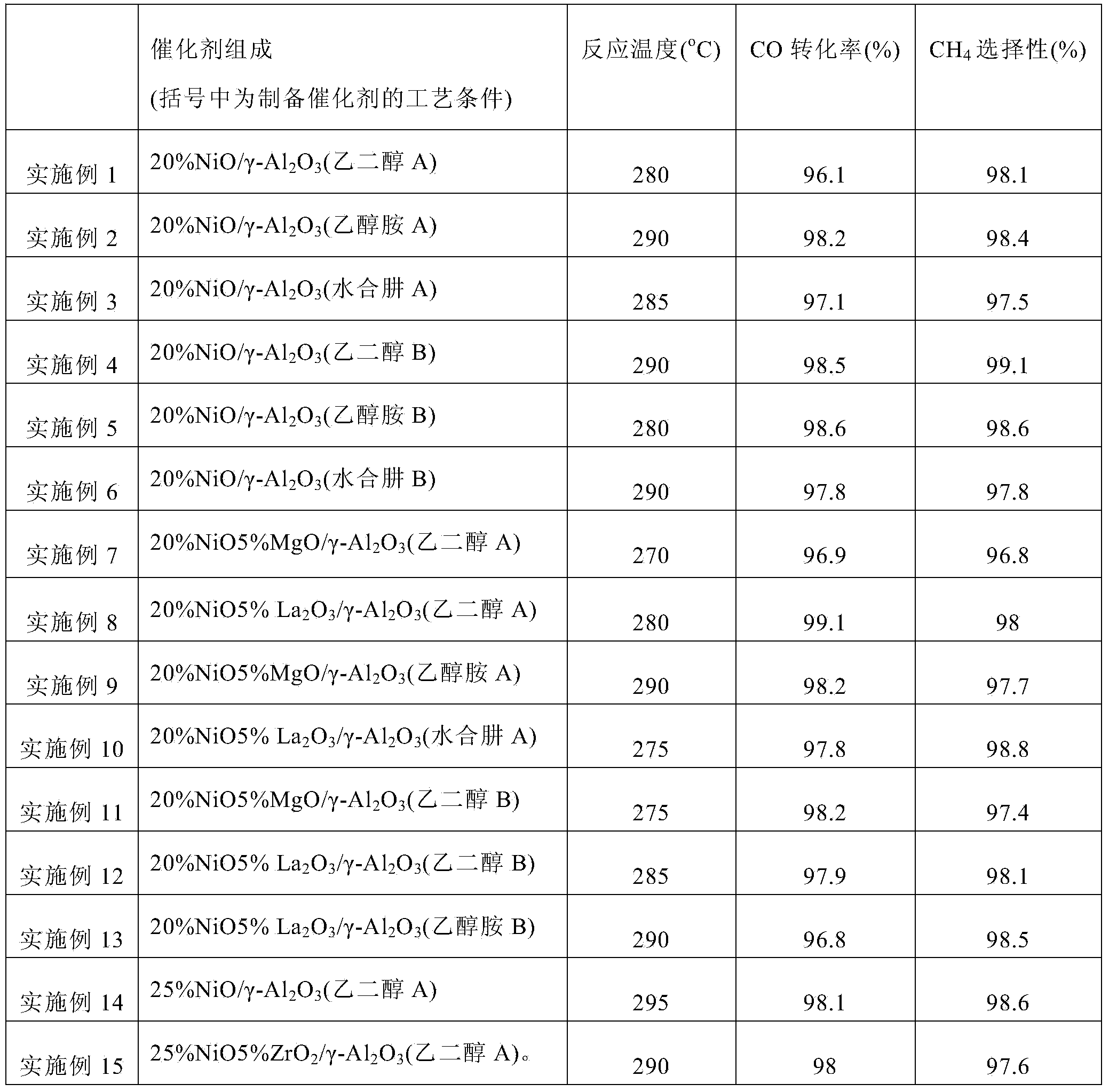

[0030] The composition and activity evaluation results of the catalysts are shown in Table 1.

Embodiment 2

[0032] The preparation method of the present embodiment comprises the following steps:

[0033] Step 1, take by weighing 294.3 grams of Al(NO 3 ) 3 9H 2 O, 77.6 g Ni(NO 3 ) 2 ·6H 2 O was dissolved in a small amount of deionized water, 305 g of ethanolamine was added, mixed evenly, and dried at 80° C. for 5 h until a gel-like product was formed.

[0034] Step 2. Transfer the gel product to a crucible or a quartz boat, put it directly into a muffle furnace with a preset temperature of 500°C, and carry out a combustion reaction for 60 minutes. Take out the solid material after combustion, wash it with deionized water, and dry it. After that, the prepared catalyst is 20%NiO / γ-Al 2 o 3 (ethanolamine A).

[0035] The composition and activity evaluation results of the catalysts are shown in Table 1.

Embodiment 3

[0037] The preparation method of the present embodiment comprises the following steps:

[0038] Step 1, take by weighing 294.3 grams of Al(NO 3 ) 3 9H 2 O, 77.6 g Ni(NO 3 ) 2 ·6H 2 O was dissolved in a small amount of deionized water, 250 g of hydrazine hydrate was added, mixed evenly, and dried at 80° C. for 5 h to form a gel-like product.

[0039] Step 2. Transfer the gel product to a crucible or a quartz boat, put it directly into a muffle furnace with a preset temperature of 500°C, and carry out a combustion reaction for 60 minutes. Take out the solid material after combustion, wash it with deionized water, and dry it. After that, the prepared catalyst is 20%NiO / γ-Al 2 o 3 (hydrazine hydrate A).

[0040] The composition and activity evaluation results of the catalysts are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com