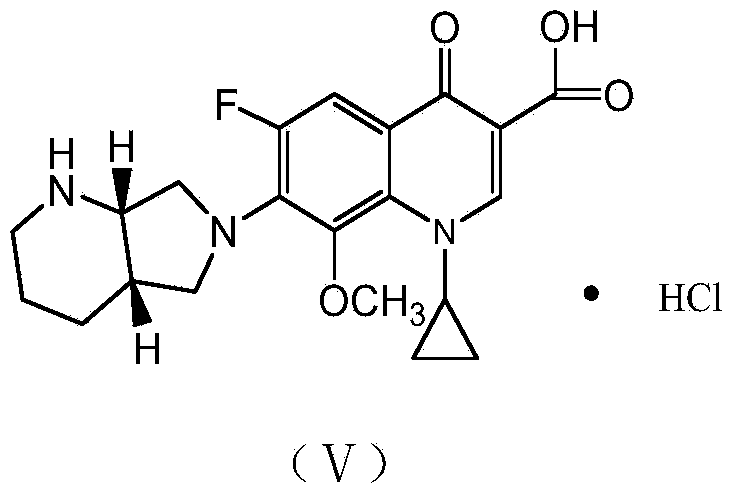

Novel synthesis method of moxifloxacin hydrochloride

A technology of moxifloxacin hydrochloride and a new method, applied in the field of medicinal chemistry, can solve the problems of low yield, expensive reagents and high cost, and achieve the effects of high yield, simple operation and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

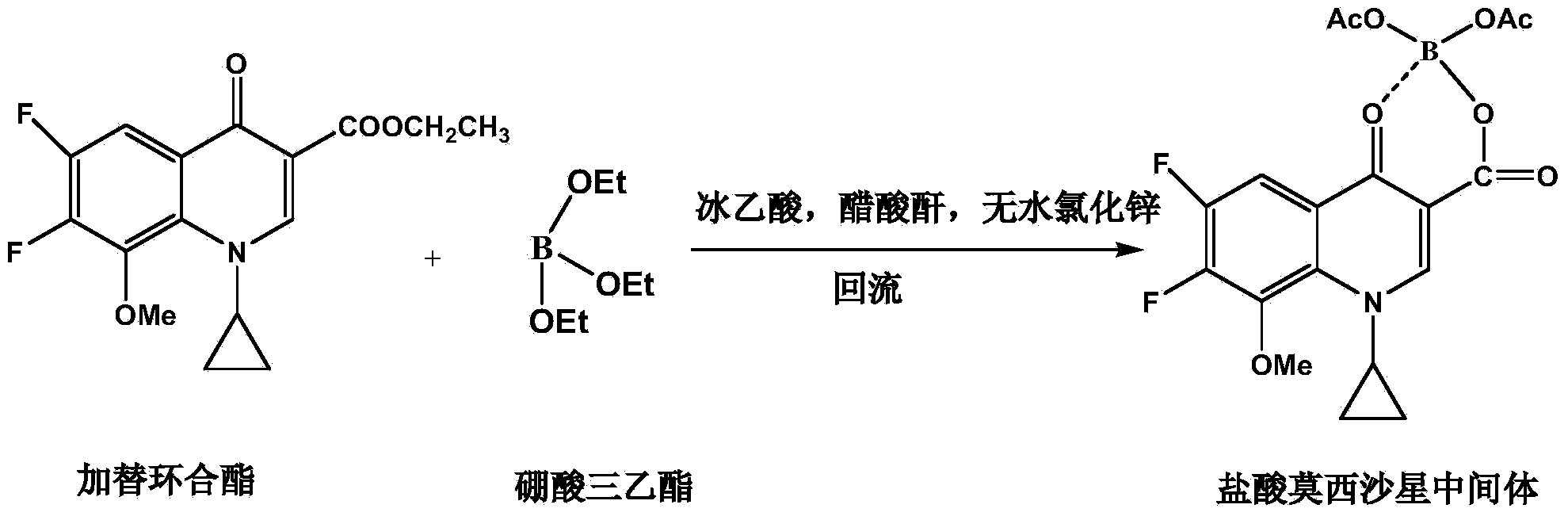

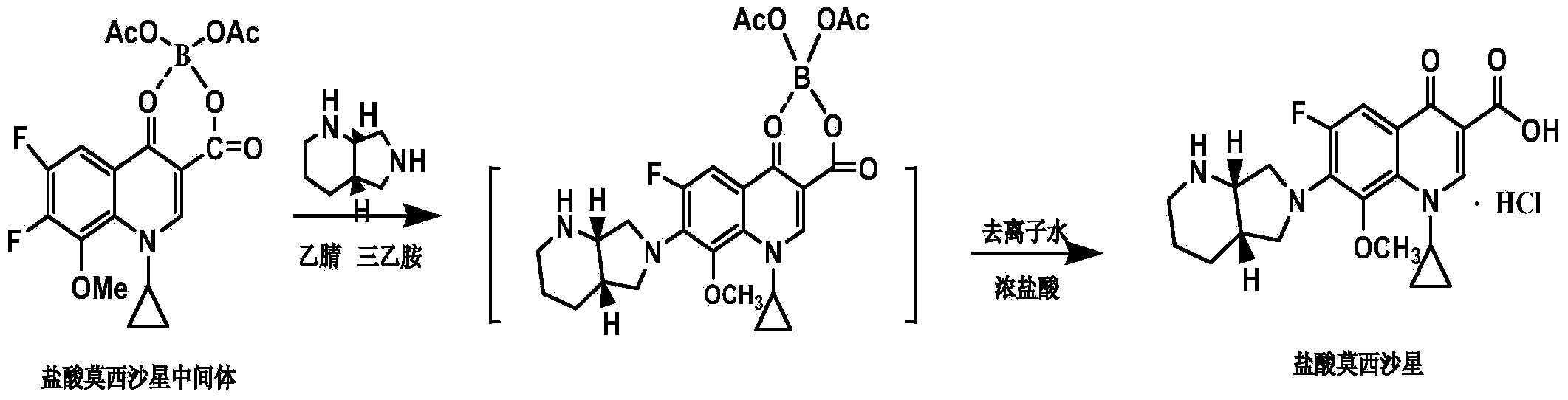

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: Moxifloxacin hydrochloride synthetic new method, it comprises the following steps:

[0027] Add 280g of acetic anhydride and 120g of glacial acetic acid to the reaction kettle in turn, stir and add 5g of anhydrous zinc chloride; heat up, add 80g of triethyl borate dropwise when the temperature in the reaction kettle is 40°C, and continue to maintain the temperature after the dropwise addition is completed Stir for 3 hours, add 150g gatiy cyclization ester after completion, heat up to 70°C, follow the reaction with TLC until the gatiy cyclization ester is completely converted; The crystalline solid was beaten twice with purified water for 20 minutes each time, the slurry was filtered, then beaten with ethanol for 20 minutes, and centrifuged again, and the obtained solid was dried with hot air at 55°C for 3 hours to obtain the intermediate 1-cyclopropyl- 6,7-Difluoro-8-methoxy-1,4-dihydro-4-oxoquinolinyl-3-carboxylic acid-O3,O4-diacetate borate 137g, yield 8...

Embodiment 2

[0030] Embodiment 2: Moxifloxacin hydrochloride synthetic new method, it comprises the following steps:

[0031] Add 280g of acetic anhydride and 120g of glacial acetic acid in sequence in the reaction kettle, stir and add 5g of anhydrous zinc chloride, raise the temperature, add 120g of triethyl borate dropwise when the temperature in the reaction kettle is 50°C, and continue stirring for 5h after the dropwise addition is completed After the completion, add 150g gatiy cyclization ester, raise the temperature to 75°C, follow the reaction with TLC until the gatiy cyclization ester is completely converted; after the reaction is completed, lower the temperature in the kettle to 25°C and stir for crystallization for 25 hours, then centrifugally filter with a centrifuge, The obtained crystalline solid was beaten twice with purified water for 30 minutes each time, and the slurry was filtered, then beaten with ethanol for 30 minutes, and centrifuged again, and the obtained solid was d...

Embodiment 3

[0034] Embodiment 3: moxifloxacin hydrochloride synthetic new method, it comprises the following steps:

[0035]Add 300g of acetic anhydride and 120g of glacial acetic acid in the reaction kettle in turn, stir and add 5g of anhydrous zinc chloride; heat up, when the temperature in the reaction kettle is 58°C, add 150g of triethyl borate dropwise, and continue stirring for 3.5 h, after the completion, add 150g gatiy cyclization ester, raise the temperature to 90°C, follow the reaction with TLC until the conversion of gatiy cyclization ester is complete; after the reaction is completed, lower the temperature in the kettle to 18°C and stir for crystallization for 28h, centrifuge filtration, and the obtained crystallization Slurry the solid with purified water for 2 times, each time for 23 minutes, filter the slurry, and then use ethanol to make a slurry for 25 minutes, then centrifuge again, and dry the obtained solid with hot air at 58°C for 4 hours to obtain the intermediate 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com