Method for preparing high-purity oleanolic acid from Aralia taibaiensis

A technology of oleanolic acid and Aralia, applied in the directions of steroids, organic chemistry, etc., can solve the problems of long preparation cycle and high cost, and achieve the effects of reducing consumption cost, less waste, and short separation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

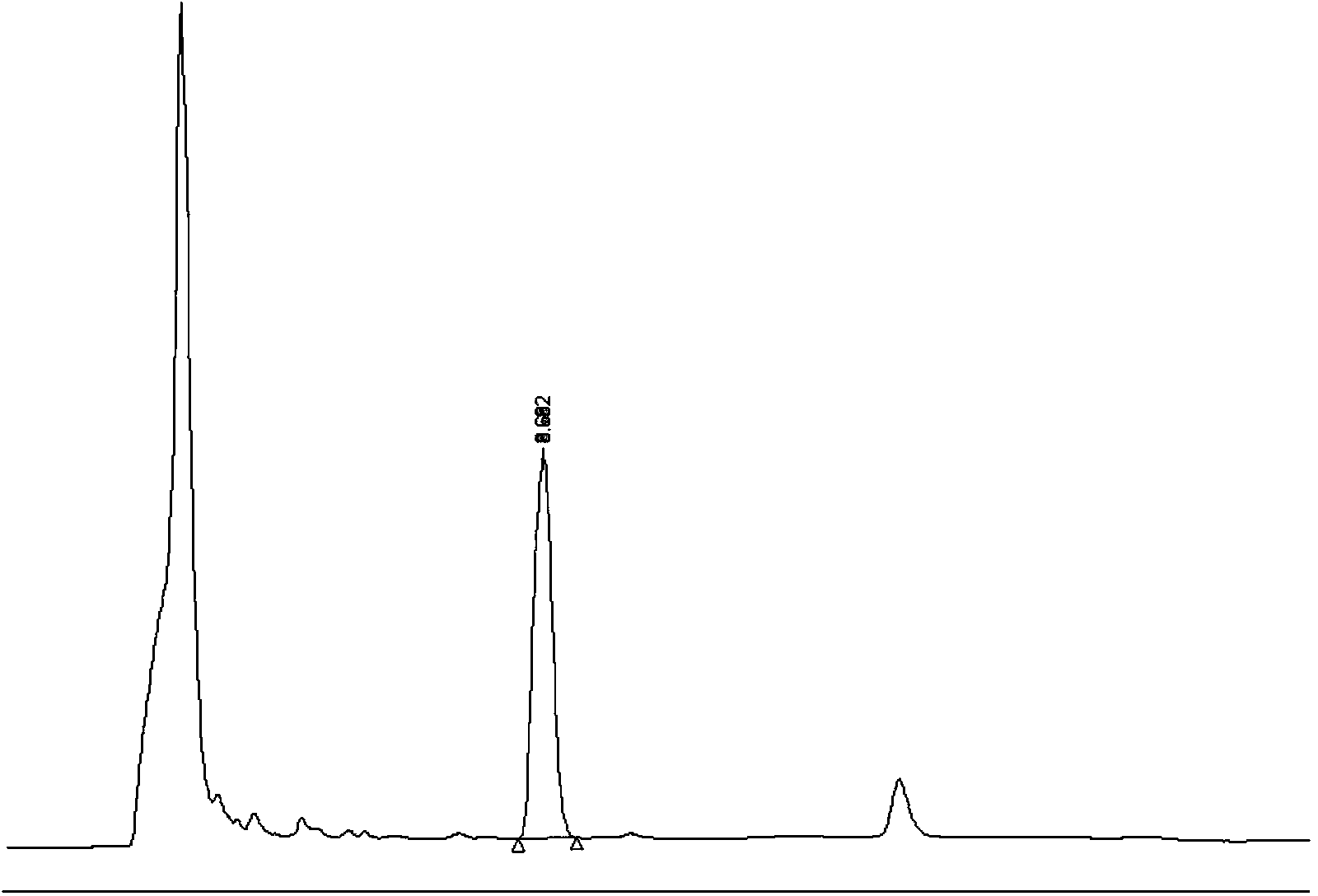

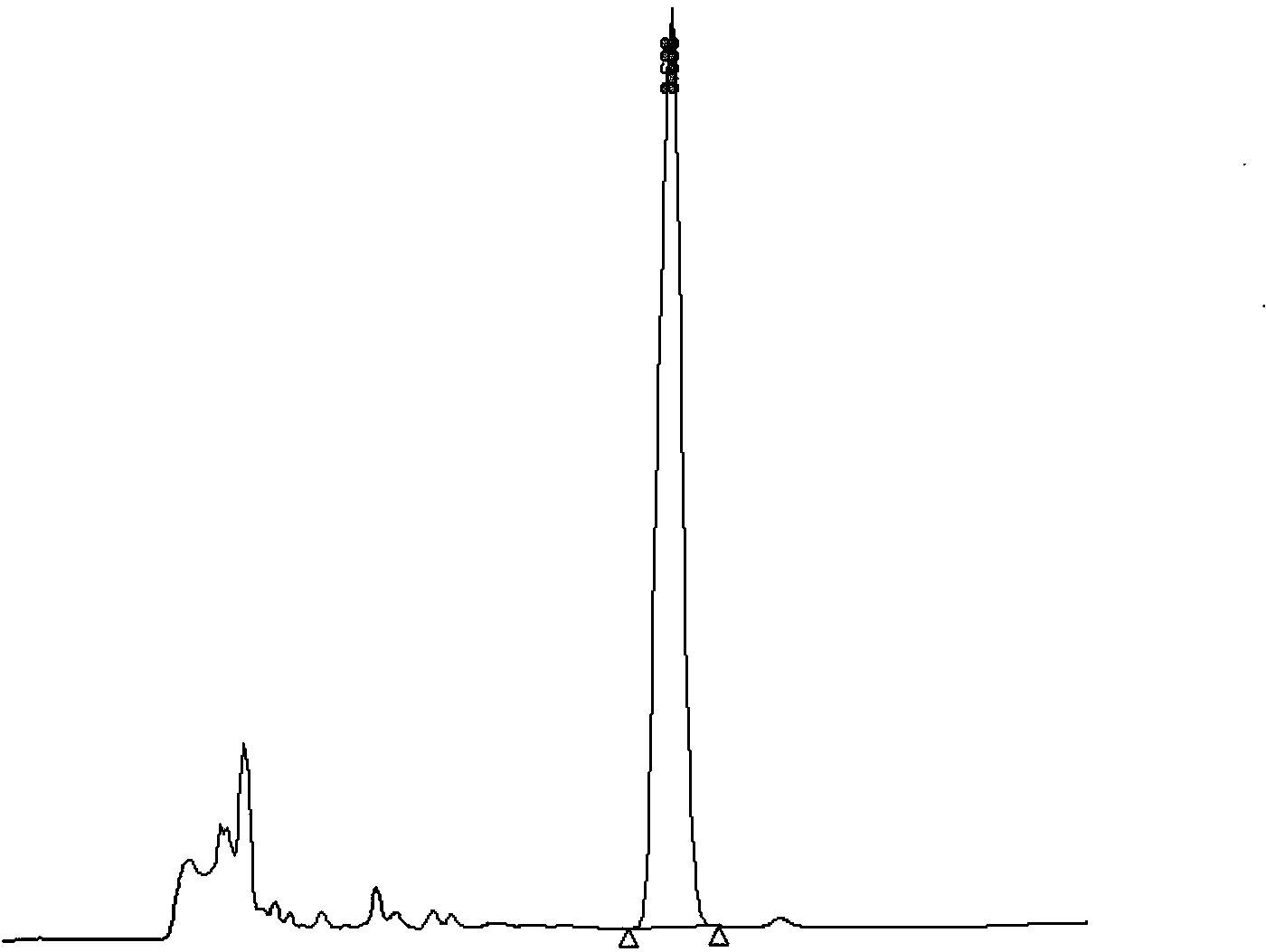

Image

Examples

Embodiment 1

[0042] A method for separating high-purity oleanolic acid from Aralia taibai, comprising the following steps:

[0043] 1) Take 1Kg of the dried rhizome of Aralia taibai, wash it with water, dry it, and crush it; add it to 10L water and boil for 1.5 hours, pour off the boiling liquid, and extract the dregs with 95% ethanol in 3 times of reflux, and the amount of ethanol used each time 6L;

[0044] 2) Combine the alcohol extract and 0.3% of the volume of the alcohol extract with activated carbon, stir and decolorize at 50°C for 1 hour; filter the activated carbon, and use 1.0mol / L sodium hydroxide aqueous solution to adjust the pH value of the ethanol extract to 11 After standing for 12 hours, filter to remove precipitates and filter impurities, and then concentrate the filtrate under reduced pressure to about 1 / 3 (5L) of the volume before concentration at 40°C with a vacuum of 0.15Mpa, and a large amount of insoluble matter is precipitated , filtered, and the insolubles filter...

Embodiment 2

[0049] A method for separating high-purity oleanolic acid from Aralia taibai, comprising the following steps:

[0050] 1) Take 1Kg of the dried rhizome of Aralia taibai, wash it with water, dry it, and crush it; add it to 12L water and boil for 1.0 hour, pour off the boiling liquid, and extract the dregs with 90% ethanol in 3 times of reflux, and the amount of ethanol used each time 8L;

[0051] 2) Combine the alcohol extract and the activated carbon with 0.6% volume of the alcohol extract, stir and decolorize at 60°C for 0.8 hours; filter the activated carbon, and adjust the pH value of the ethanol extract to 11 for the decolorized alcohol extract with 0.6mol / L sodium hydroxide aqueous solution After standing still for 10 hours, filter to remove precipitates and filter impurities, and concentrate the filtrate under reduced pressure to about 1 / 4 (6L) of the volume before concentration at 55°C with a vacuum degree of 0.12Mpa, and a large amount of insoluble matter precipitates ...

Embodiment 3

[0056] A method for separating high-purity oleanolic acid from Aralia taibai, comprising the following steps:

[0057] 1) Take 1Kg of the dried rhizome of Aralia taibai, wash it with water, dry it, and crush it; add it to 15L of water and boil for 2.0 hours, pour off the boiling liquid, and extract the dregs with 85% ethanol in 3 times of reflux, and the amount of ethanol used each time 12L;

[0058] 2) Combine the alcohol extract and the activated carbon with 1.0% volume of the alcohol extract, stir and decolorize at 55°C for 0.6 hours; filter the activated carbon, and use 0.8mol / L sodium hydroxide aqueous solution to adjust the pH value of the ethanol extract to 11 After standing for 8 hours, filter, remove precipitates, filter impurities, and concentrate the filtrate under reduced pressure to about 1 / 5 (7L) of the volume before concentration at 60°C with a vacuum degree of 0.09Mpa, and a large amount of insoluble matter is precipitated , filter, filter out insoluble matter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com