A preparing method of a low-sulfur diesel oil lubrication improver

A technology of lubrication improver and low-sulfur diesel oil, which is applied in the petroleum industry, fuel additives, liquid carbon-containing fuels, etc., and can solve problems such as inconvenience, equipment corrosion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

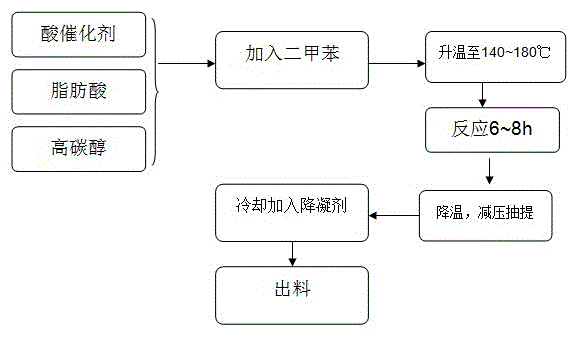

[0020] See figure 1 , a preparation method of a low-sulfur diesel lubricity improver, the specific steps are as follows:

[0021] A. Add fatty acid: high carbon alcohol molar ratio = 0.8:1 ~ 1.4:1 into the 500L reactor;

[0022] B. The amount of acid catalyst added is 1‰~1% of the sum of fatty acid and higher alcohol mass;

[0023] C. The amount of xylene added is 0.8 to 1.2 times the sum of the fatty acid and higher alcohol mass, and the temperature is raised to 140 to 180°C, and the reaction is carried out for 6 to 8 hours;

[0024] D, xylene is extracted under reduced pressure, cooled to room temperature;

[0025] E. Add pour point depressant, the amount added is 10-35% of the sum of fatty acid and higher carbon alcohol, and stir for 30 minutes.

[0026] F, filter the material.

[0027] The acid catalyst is one or a mixture of concentrated sulfuric acid or sulfonic acid or sulfamic acid or Y-type molecular sieve solid acid or heteropolyacid or aluminosilicate solid acid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com