MEMS (micro-electromechanical system) semiconductor gas sensor as well as manufacturing method thereof and gas detection method

A gas sensor and semiconductor technology, applied in the direction of semiconductor devices, electric solid devices, fluid velocity measurement, etc., can solve the problem of inability to respond to recovery rate, linearity, selective compensation, inability to effectively reduce the adverse effects of ambient temperature, and uncontrollable Changes in sensor performance and other issues to achieve the effect of ensuring performance, reducing test errors, and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

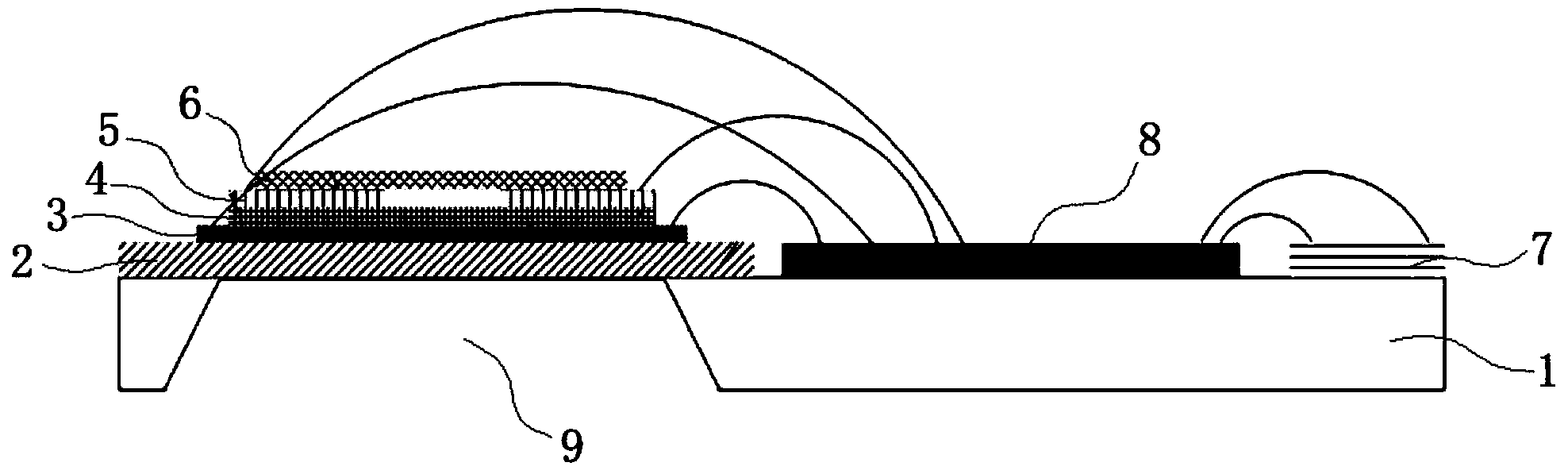

[0035] A MEMS semiconductor gas sensor, comprising a substrate 1 with a hollow portion 9, a sensing module, a control module and a temperature detection module; the sensing module is formed on the substrate 1, and the sensing module includes sequentially stacked The first insulating layer 2, the heating resistor 3, the second insulating layer 4, the test electrode 5 and the gas sensitive layer 6, wherein the first insulating layer 2 is arranged on the substrate 1 in a state of covering the hollow portion 9, The upper surface of the gas-sensitive layer 6 is exposed to the gas to be measured; the temperature detection module can be a related product with a temperature measurement function, such as a temperature sensitive resistor, a temperature sensor, etc., and the control module is selected from those with a control function. Various controllers, such as single-chip microcomputer, DSP (digital signal processor), FPGA (field programmable gate array), programmable logic controlle...

Embodiment 2

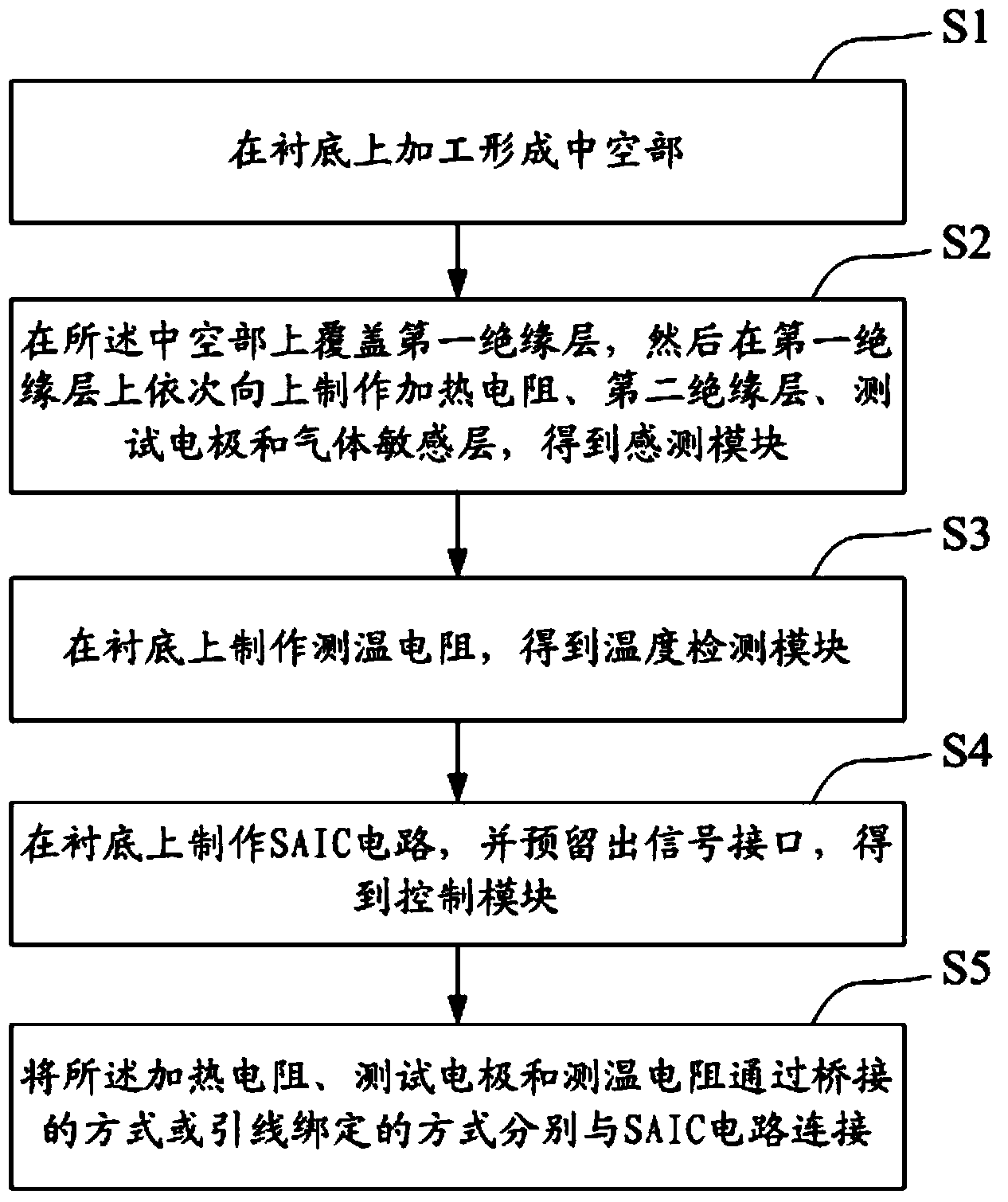

[0038] Please see attached figure 1, a MEMS semiconductor gas sensor of the present invention includes a substrate 1 having a hollow portion 9 and a sensing module, an ASIC circuit 8 and a temperature measuring resistor 7 respectively formed on the substrate 1; the sensing module includes a bottom-up The first insulating layer 2, the heating resistor 3, the second insulating layer 4, the test electrode 5 and the gas sensitive layer 6 are stacked, wherein the first insulating layer 2 is arranged on the substrate 1 in the state of covering the hollow part 9, and the gas The upper surface of the sensitive layer 6 is exposed to the gas to be measured. The temperature measuring resistor 7 , the heating resistor 3 and the testing electrode 5 communicate with the ASIC circuit 8 respectively. In this embodiment, the substrate 1 is made of silicon wafers polished on both sides and oxidized on both sides; the heating resistor 3 and the temperature measuring resistor 7 are made of plati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com