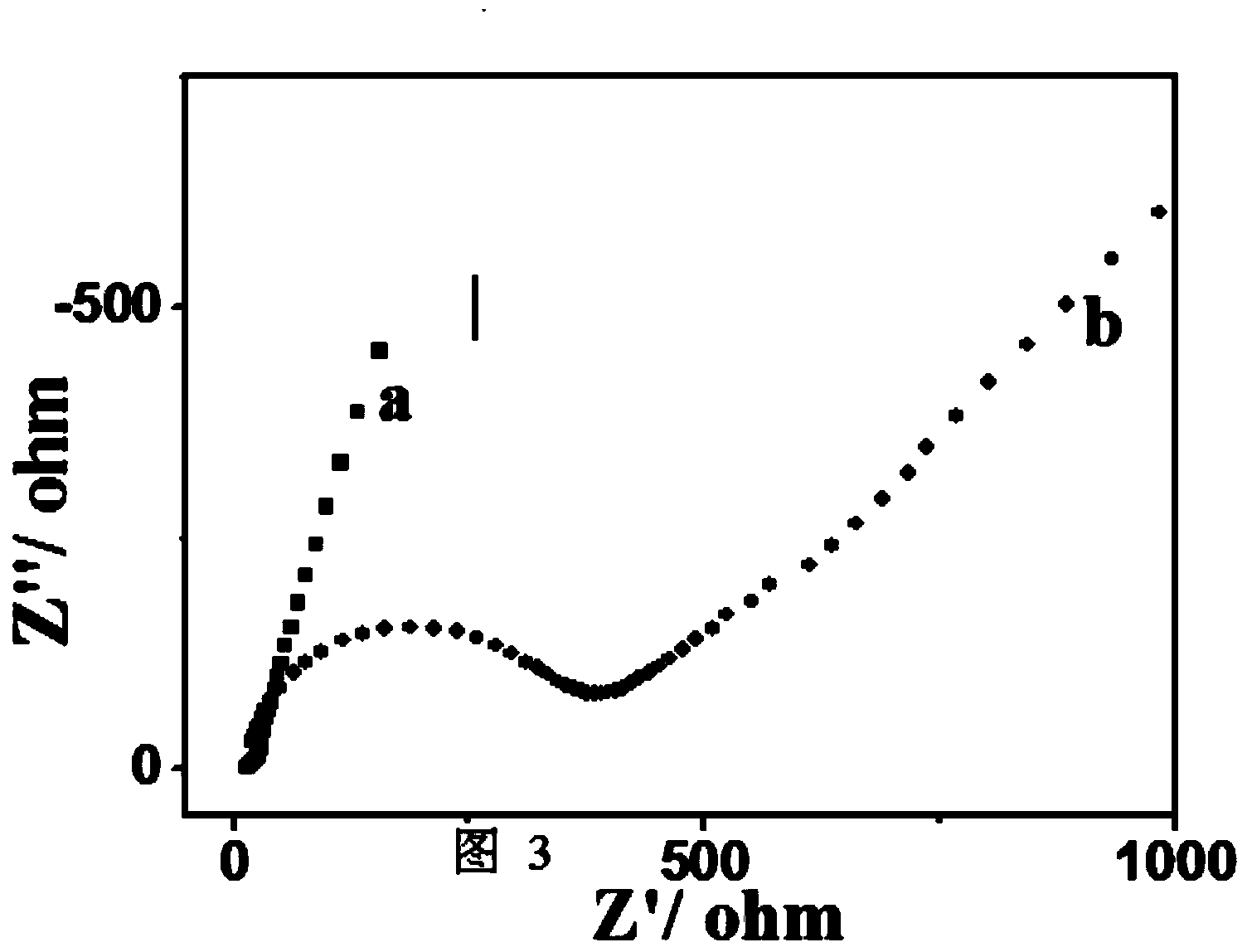

Polypyrrole/silver@silver chloride core-shell structure nano wire, and preparation method and application thereof

A silver-silver chloride, core-shell structure technology, applied in the direction of chemical reaction of materials for analysis, material electrochemical variables, chemiluminescence/bioluminescence, etc., can solve problems such as limiting visible light absorption and reducing solar light utilization. , to achieve the effects of good selectivity, improved photocurrent conversion efficiency, and fast response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) Synthesis of silver nanowires

[0038] Silver nanowires were prepared by an improved polyol reduction method, adding 15ml of ethylene glycol solution with polyvinylpyrrolidone mass concentration of 0.0065g / ml into a three-necked flask, and placing it in an oil bath at 160°C Heat in the pot for 5 minutes. Then, AgNO was added to the three-necked flask 3 2ml of ethylene glycol solution with a concentration of 0.25M was added, followed by 0.3ml of 0.05M NaCl solution, and heated at 160°C for 15 minutes. Stirring is required throughout the process. The product was first washed three times with acetone to remove ethylene glycol and remaining polyvinylpyrrolidone, then washed three times with distilled water to remove acetone, and the rotating speed of the centrifuge was 2000 rpm.

[0039] (2) Preparation of silver silver chloride nanowires

[0040] The previously synthesized silver nanowires were added to 2ml of 0.1M NaCl solution, and then Fe sheets (1cm×3cm) treate...

Embodiment 2

[0045] (1) Synthesis of silver nanowires

[0046] Silver nanowires were prepared by an improved polyalcohol reduction method, adding 15ml of ethylene glycol solution with a mass concentration of polyvinylpyrrolidone of 0.005g / ml into a three-necked flask, and placing it in an oil bath at 160°C Heat in the pot for 5 minutes. Then, AgNO was added to the three-necked flask 3 2ml of ethylene glycol solution with a concentration of 0.25M was added, followed by 0.3ml of 0.05M NaCl solution, and heated at 160°C for 15 minutes. Stirring is required throughout the process. The product was first washed three times with acetone to remove ethylene glycol and remaining polyvinylpyrrolidone, then washed three times with distilled water to remove acetone, and the rotating speed of the centrifuge was 2000 rpm.

[0047] (2) Preparation of silver silver chloride nanowires

[0048] The specific operation is the same as the preparation of (2) silver silver chloride nanowires in Example 1.

...

Embodiment 3

[0052] (1) Synthesis of silver nanowires

[0053] Silver nanowires are prepared by an improved polyol reduction method, adding 15ml of ethylene glycol solution with a mass concentration of polyvinylpyrrolidone of 0.01g / ml into a three-necked flask, and placing it in an oil bath at 160°C Heat in the pot for 5 minutes. Then, AgNO was added to the three-necked flask 3 2ml of ethylene glycol solution with a concentration of 0.25M was added, followed by 0.3ml of 0.05M NaCl solution, and heated at 160°C for 15 minutes. Stirring is required throughout the process. The product was first washed three times with acetone to remove ethylene glycol and remaining polyvinylpyrrolidone, and then washed three times with distilled water to remove acetone, and the rotating speed of the centrifuge was 2000 rpm.

[0054] (2) Preparation of silver silver chloride nanowires

[0055] The specific operation is the same as the preparation of (2) silver silver chloride nanowires in Example 1.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com