Electromagnetic-wave absorbing material with interstitial modulation characteristics and production method of electromagnetic-wave absorbing material

A technology for absorbing materials and electromagnetic waves, applied in the field of electromagnetic wave materials, can solve the problems of small bandwidth range, low absorption rate, and difficulty in achieving effective absorption strength, etc., and achieve the effect of wide operating frequency band, strong absorption capacity, and meeting the needs of electromagnetic wave absorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

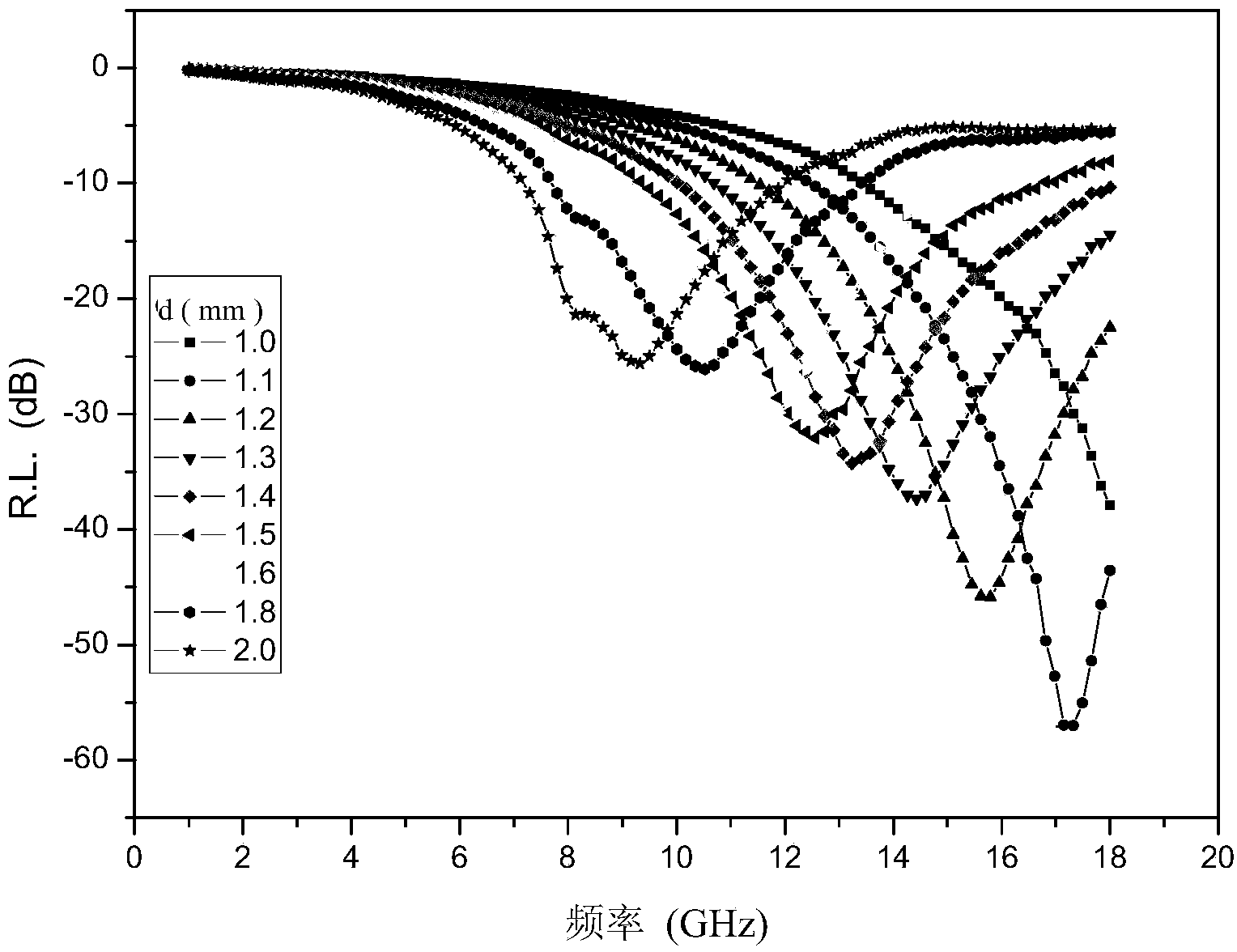

[0024] Weigh 250g of rare earth Nd and 750g of iron to prepare a master alloy with complete planar anisotropy, which is rapidly solidified into alloy thin strips (1-2cm wide, 0.2-0.4mm thick) by melting, heat-treated at 1000°C for 2 days, and broken into granules Coarse powder with a diameter of 50-100 microns, in N 2 Nitriding at 480°C for 5 hours in an atmosphere, and determining the nitrogen content by weighing method, to obtain Nd 2 Fe 17 N 3.3 . After nitriding, the powder was ball milled for 12 hours in a solution of gasoline and grinding aid (oleic acid 3% Vol). Drain the liquid after the ball mill is discharged, dry the magnetic powder, mix the magnetic powder and paraffin wax evenly at a mass ratio of 4:1, bond and press mold it into a cylindrical ring with an inner diameter of 3.04 mm and an outer diameter of 7.00 mm. Electromagnetic properties were measured on an Agilent vector network analyzer. According to the measured electromagnetic parameters, the absorpti...

Embodiment 2

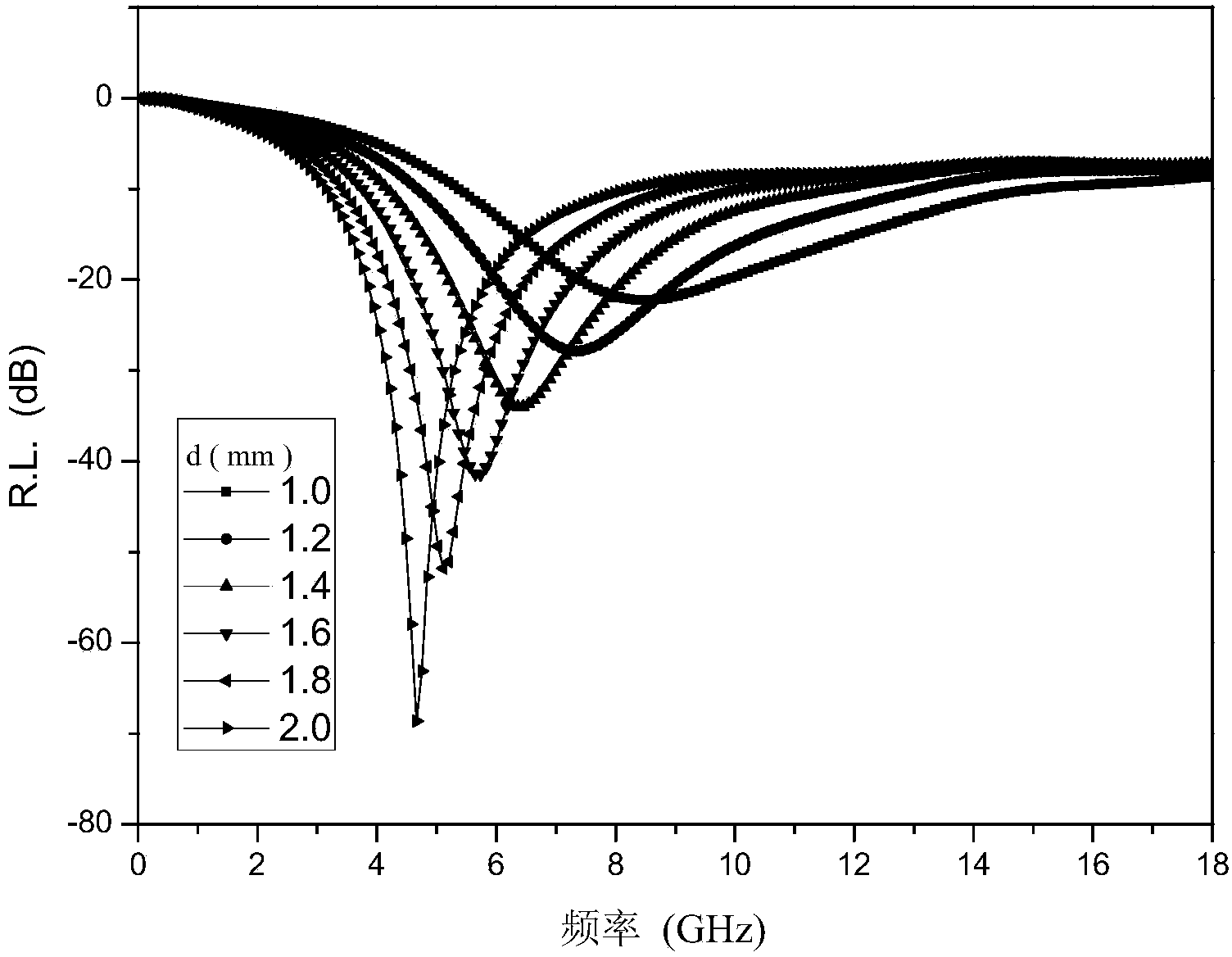

[0026] Weigh 220g of rare earth Nd, 30g of rare earth Sm and 750g of iron to prepare a master alloy with partial cone anisotropy, which is rapidly solidified into an alloy ingot by smelting, heat-treated at 1100°C for 5 days, and broken into coarse particles with a particle size of 50-100 microns. Powder, in NH 3 Nitriding at 460°C for 8 hours in an atmosphere, and determining the nitrogen content by weighing method to obtain Nd 1.75 SM 0.25 Fe 17 N 3.5 . After nitriding, the powder was ball milled for 15 hours in a solution of gasoline and grinding aid (oleic acid 3% Vol). Drain the liquid after the ball mill is discharged, dry the magnetic powder, mix the magnetic powder and paraffin wax evenly at a mass ratio of 4:1, bond and press mold it into a cylindrical ring with an inner diameter of 3.04 mm and an outer diameter of 7.00 mm. Electromagnetic properties were measured on an Agilent vector network analyzer. According to the measured electromagnetic parameters, the ab...

Embodiment 3

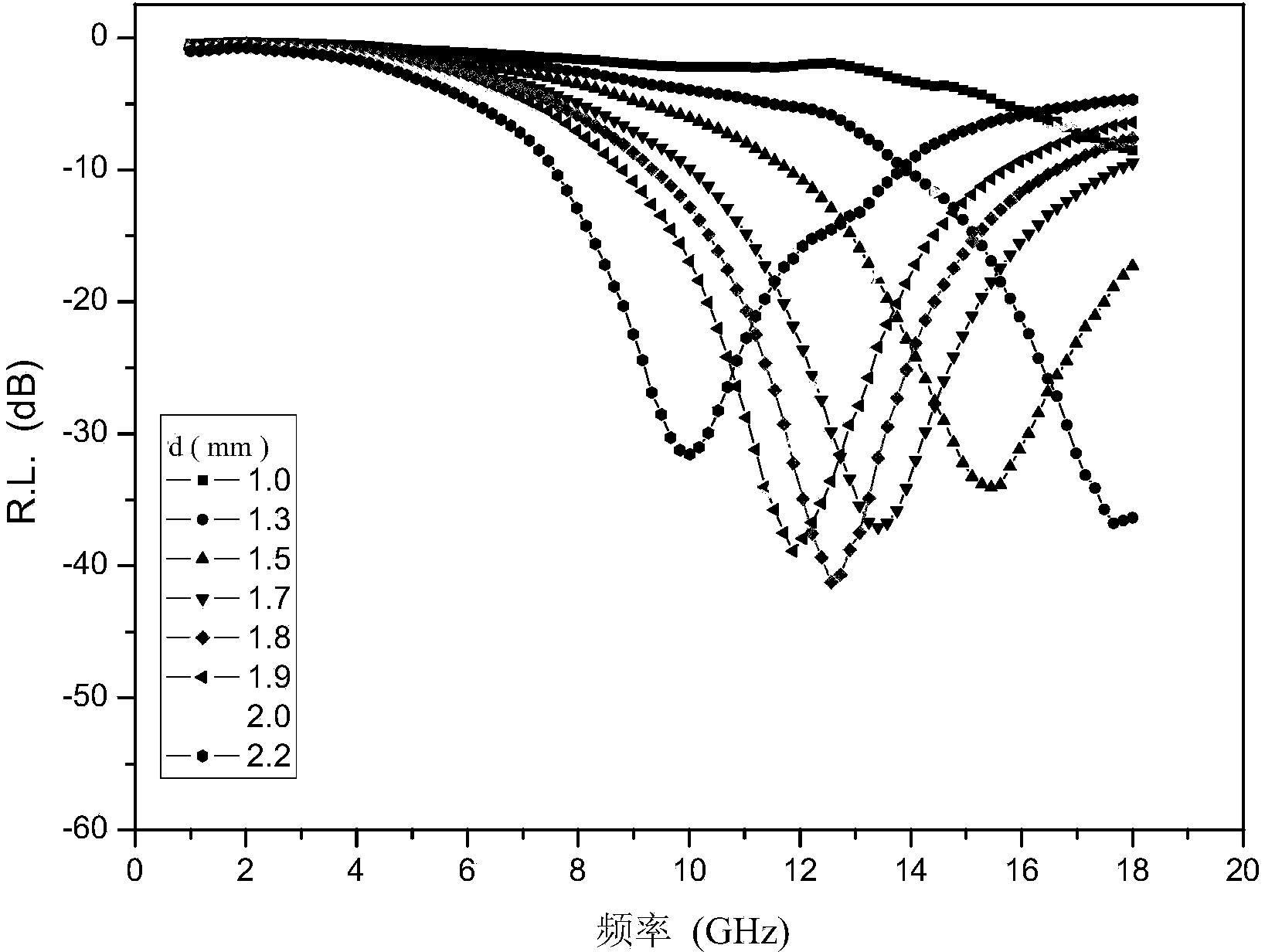

[0028] Weigh 190g of rare earth Nd, 50g of rare earth Sm, and 750g of iron to prepare a master alloy with partial cone anisotropy, which is rapidly solidified into an alloy ingot by smelting, heat-treated at 1050°C for 7 days, and broken into particles with a particle size of 50-100 microns Meal, in CH 4 Carburize at 460°C for 8 hours in an atmosphere, and determine the carbon content by weighing method to obtain Nd 1.65 SM 0.35 Fe 17 C 2.5 . After carbonization, the powder was ball-milled for 15 hours in a solution of gasoline and grinding aid (oleic acid 3% Vol). Drain the liquid after the ball mill is discharged, dry the magnetic powder, mix the magnetic powder and paraffin wax evenly at a mass ratio of 4:1, bond and press mold it into a cylindrical ring with an inner diameter of 3.04 mm and an outer diameter of 7.00 mm. Electromagnetic properties were measured on an Agilent vector network analyzer. According to the measured electromagnetic parameters, the absorption ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com