Ganoderma spore wall breaking process

A technology of Ganoderma lucidum spores and microwave treatment, which is applied in food science, plant raw materials, applications, etc., can solve the problems of Ganoderma lucidum spores’ nutrient destruction, low wall breaking rate, and easy introduction of other impurities, so as to achieve comprehensive preservation of nutrients and improve Nutritional value, the effect of increasing the broken wall ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

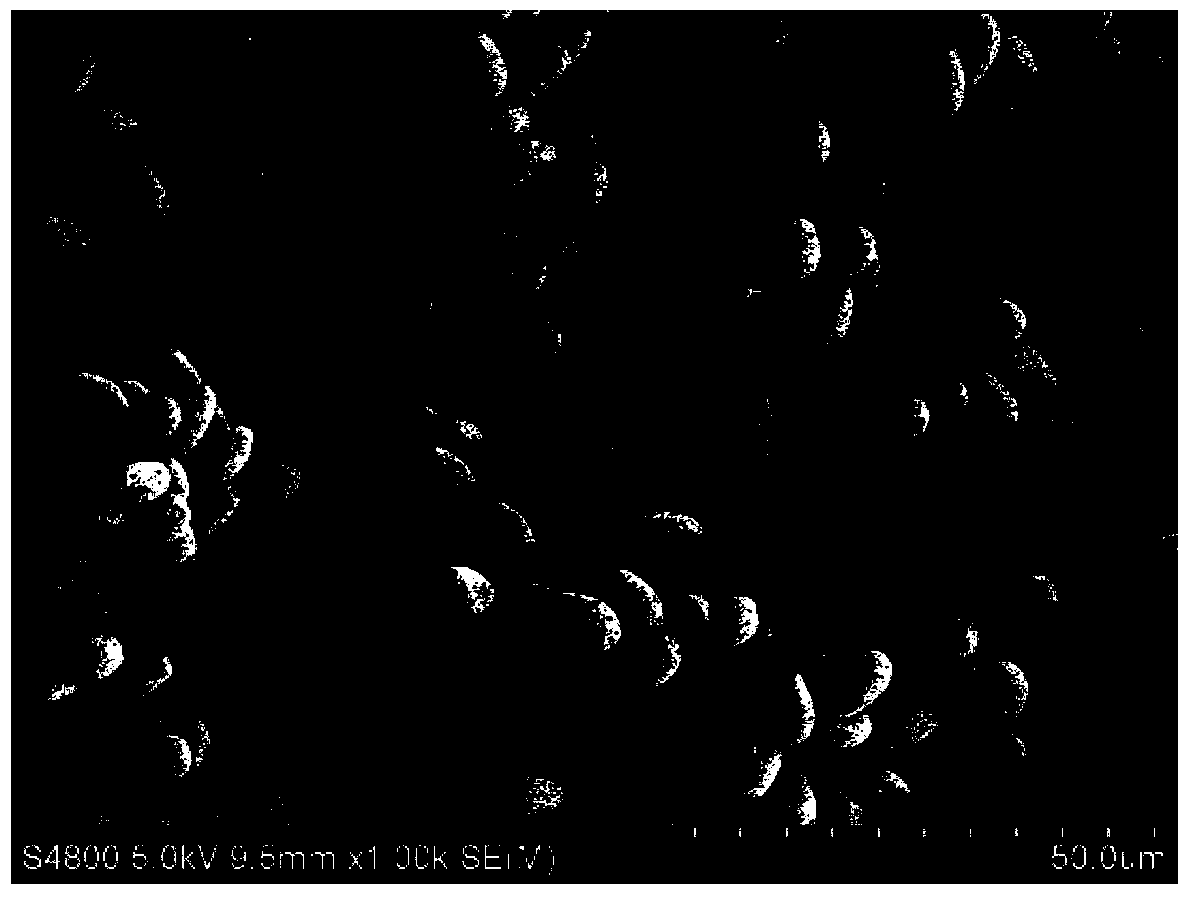

[0046] Electron microscope analysis of Ganoderma lucidum spores without any treatment, the results are as follows figure 1 shown. Take Ganoderma lucidum spores and analyze their water content, which is about 10%. They are processed by spray drying, freeze drying, vacuum drying, etc. to obtain a variety of Ganoderma lucidum spores with a water content ranging from 5% to 9%, and prepare for the spore wall breaking. . After testing, the Ganoderma lucidum polysaccharide content in the raw material Ganoderma lucidum spores (unbroken wall) is 3.32%, and the content of Ganoderma lucidum triterpenoids is 1.12%.

Embodiment 2

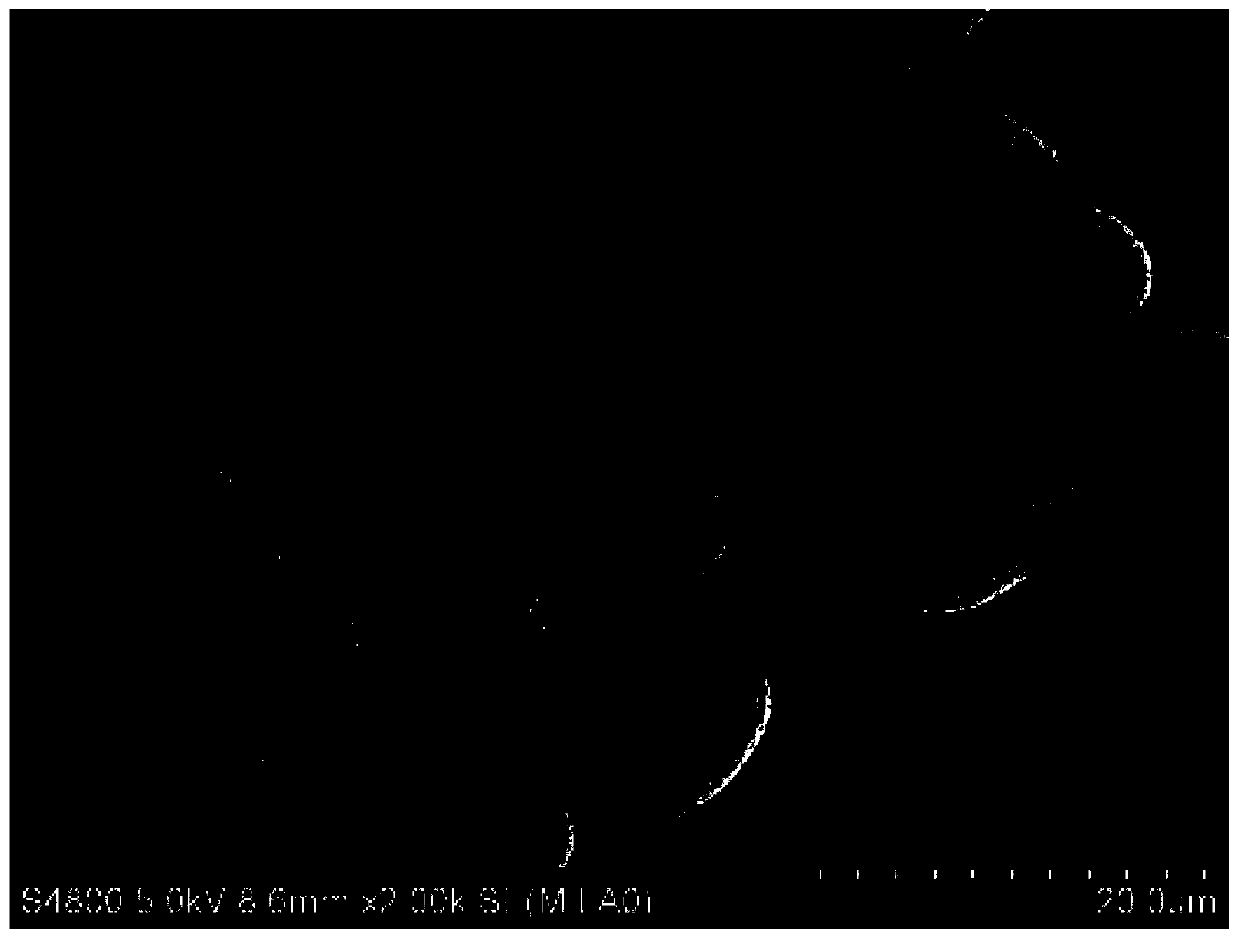

[0048] The ganoderma lucidum spores were taken, the water content of the ganoderma lucidum spores was analyzed and determined to be 10%, and then freeze-dried to a water content of 5%. Low-temperature vacuum microwave treatment of Ganoderma lucidum spores, the temperature is 5-50°C, the microwave power is 500-1000W, and the treatment time varies from 10 minutes to 1 hour. The pretreated Ganoderma lucidum spores are subjected to airflow crushing at a pressure of 0.5-2 MPa and circulated for 20 minutes to obtain the broken Ganoderma lucidum spore powder. The color of the spore powder is sauce brown, the taste is delicate, and the taste is slightly bitter, and the bitterness can be ignored after flushing. Electron microscope analysis, the results of electron microscope analysis of Ganoderma lucidum spores after the low-temperature vacuum microwave pretreatment of group 204 in this embodiment 2 for 20 minutes, such as figure 2 shown. After the ganoderma lucidum spores of groupi...

Embodiment 3

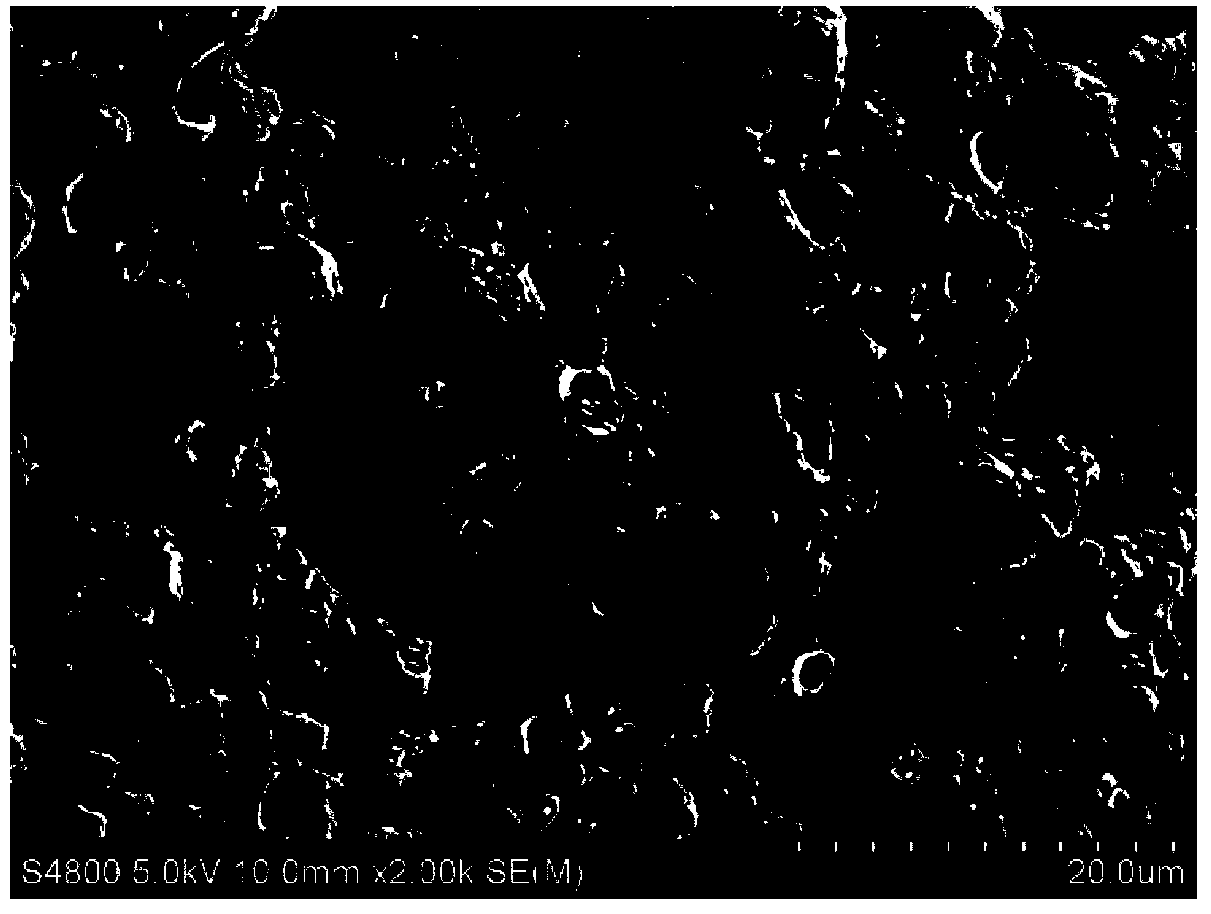

[0056] Take the Ganoderma lucidum spores (water content 5%-10%) treated in Example 1 and irradiate them with a 500-2000W ultraviolet lamp for a total of 10-30 minutes. The wavelength of ultraviolet light is 240-270nm. The distance between the ultraviolet light source and the spore powder is 10-30 cm. Grouping 302 in embodiment 3, the ganoderma lucidum spore electron microscope analysis result after ultraviolet light illumination treatment is as follows Figure 4 shown. The pretreated Ganoderma lucidum spores are subjected to jet crushing at a pressure of 1-2 MPa, and after 25 minutes of circulation, the broken Ganoderma lucidum spore powder is obtained. Example 3 Grouping experiment parameters are shown in Table 3. The scoring results are shown in Table 4.

[0057] table 3

[0058]

[0059] The scoring results are as follows:

[0060] Table 4

[0061] group

[0062] After ultraviolet radiation pretreatment, the nutritional components of Ganoderma lucidum sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Molar concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com