A kind of ginkgo ketone ester solid self-microemulsion sustained-release pellets and preparation method thereof

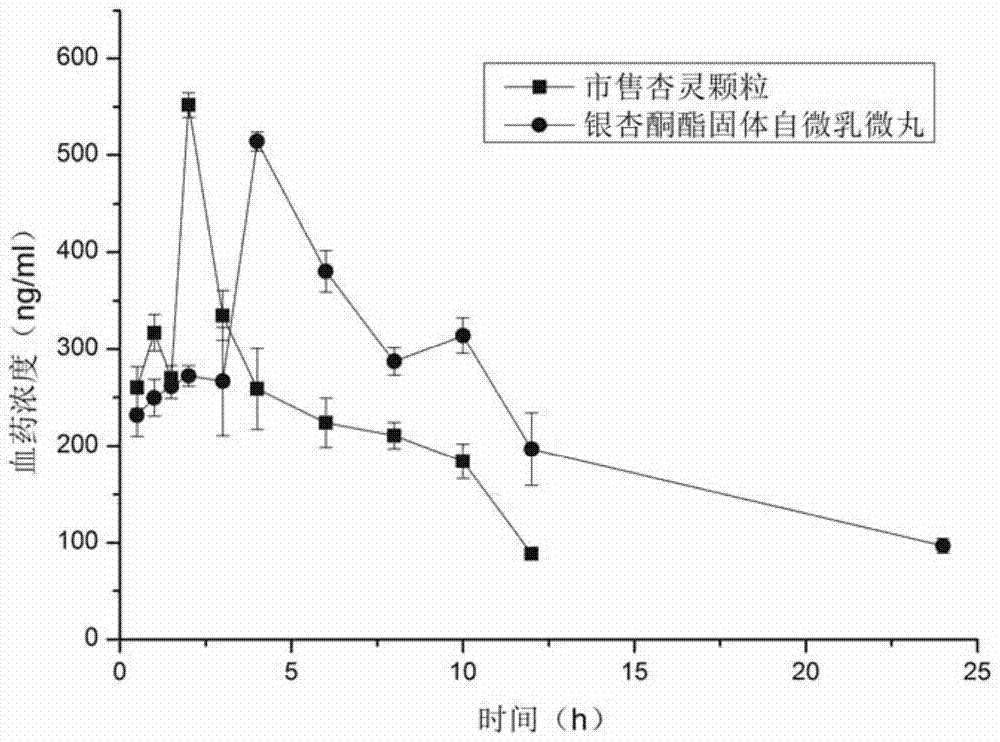

A technology of ginkgo ketone ester and sustained-release pellets is applied in the directions of medical raw materials derived from Ginkgo biloba, bulk delivery, cardiovascular system diseases, etc. It can improve the oral bioavailability, prolong the action time and improve the stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

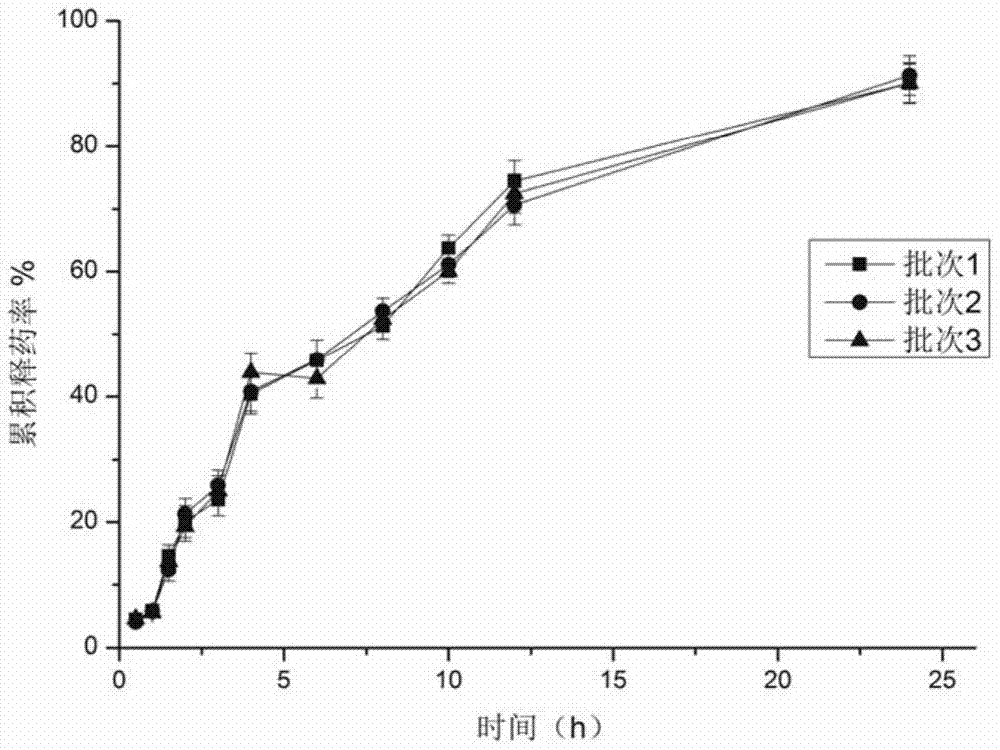

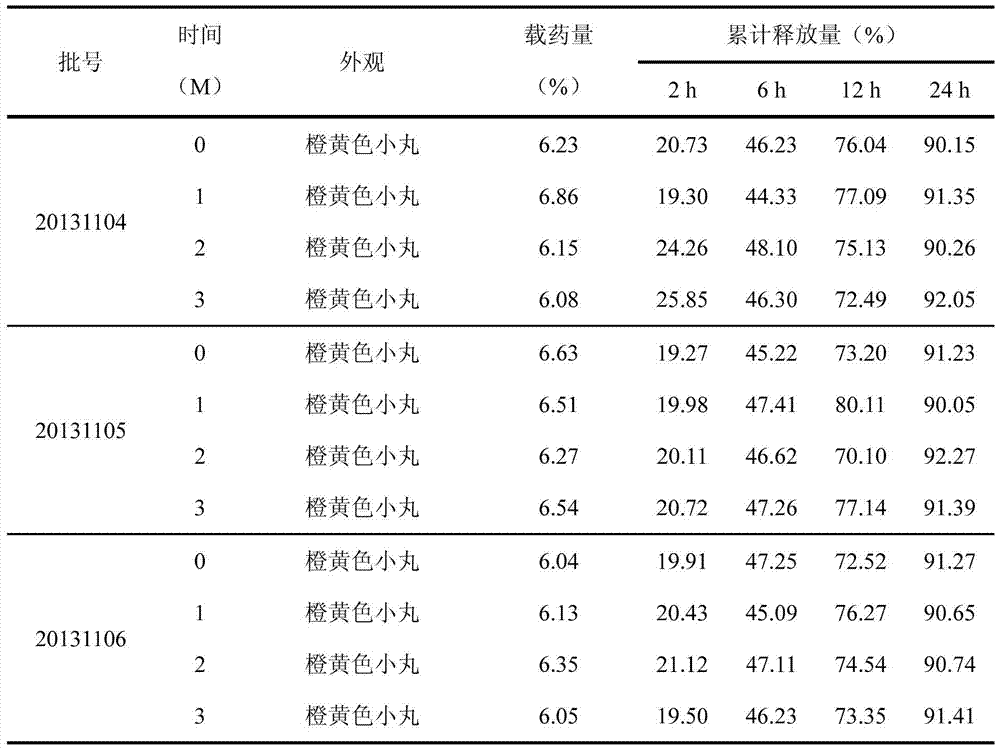

Embodiment 1

[0026] Weigh 45g of polyoxyethylene castor oil EL35, 45g of polyethylene glycol 400 and 10g of medium chain oil, stir evenly, add 10g of ginkgo ketone ester, stir for 24h, and filter to obtain ginkgo ketone ester self-microemulsion. In addition, 90 g of microcrystalline cellulose and 10 g of crospovidone were weighed, mixed evenly, and the above-mentioned ginkgo ketone ester self-microemulsion was added to prepare a soft material, which was extruded and spheronized to obtain a drug-containing pill core. Dry the pellet core containing the drug in a drying oven at 60°C for 2 hours, and take it out.

[0027] Preparation of coating solution: ethyl cellulose 1g, talc powder 0.3g and PEG4000 0.9g, dissolved in 100mL absolute ethanol solution to obtain coating solution; weigh 100g containing pill core, put it into extrusion spheronization coating machine for preheating After 10 minutes, coat with coating solution. After coating, the coated pellets were taken out and dried in a dryin...

Embodiment 2

[0029] Weigh 40 g of polyoxyethylene castor oil EL35, 40 g of polyethylene glycol 400 and 20 g of medium chain oil, stir well, add 20 g of ginkgo ketone ester, stir for 24 hours, and filter to obtain ginkgo ketone ester self-microemulsion. In addition, 90 g of microcrystalline cellulose and 10 g of crospovidone were weighed, mixed evenly, and the above-mentioned ginkgo ketone ester self-microemulsion was added to prepare a soft material, which was extruded and spheronized to obtain a drug-containing pill core. Dry the pellet core containing the drug in a drying oven at 60°C for 2 hours, and take it out.

[0030] Preparation of coating solution: ethyl cellulose 3g, talc powder 0.45g, PEG4000 0.4g, dissolved in 100mL absolute ethanol solution to obtain coating solution; weigh 100g containing pill core, put it into extrusion spheronization coating machine for preheating After 10 minutes, coat with coating solution. After coating, the coated pellets were taken out and dried in a ...

Embodiment 3

[0032] Weigh 42.5g of polyoxyethylene castor oil EL35, 42.5g of polyethylene glycol 400 and 15g of medium chain oil, stir evenly, add 20g of ginkgo ketone ester, stir for 24h, and filter to obtain ginkgo ketone ester self-microemulsion. In addition, 80 g of microcrystalline cellulose and 20 g of crospovidone were weighed, mixed evenly, and the above-mentioned ginkgo ketone ester self-microemulsion was added to prepare a soft material, which was extruded and spheronized to obtain a drug-containing pill core. Dry the pellet core containing the drug in a drying oven at 60°C for 2 hours, and take it out.

[0033] Preparation of coating liquid: ethyl cellulose 3g, talc powder 1.2g, PEG4000 0.6g, dissolved in 100mL absolute ethanol solution to obtain coating liquid; weigh 100g containing pill core, put it into extrusion spheronizing coating machine for preheating After 10 minutes, coat with coating solution. After coating, the coated pellets were taken out and dried in a drying ove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com