Millimeter wave chip carrier based on high temperature co-fired ceramic and manufacturing method thereof

A technology of high-temperature co-fired ceramics and chip casings, which is applied in the manufacture of semiconductor/solid-state devices, electrical components, and electrical solid-state devices. It can solve the problems of high processing accuracy, limited application, high dielectric constant and dielectric loss, and achieve good isolation , to avoid the effect of resonance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

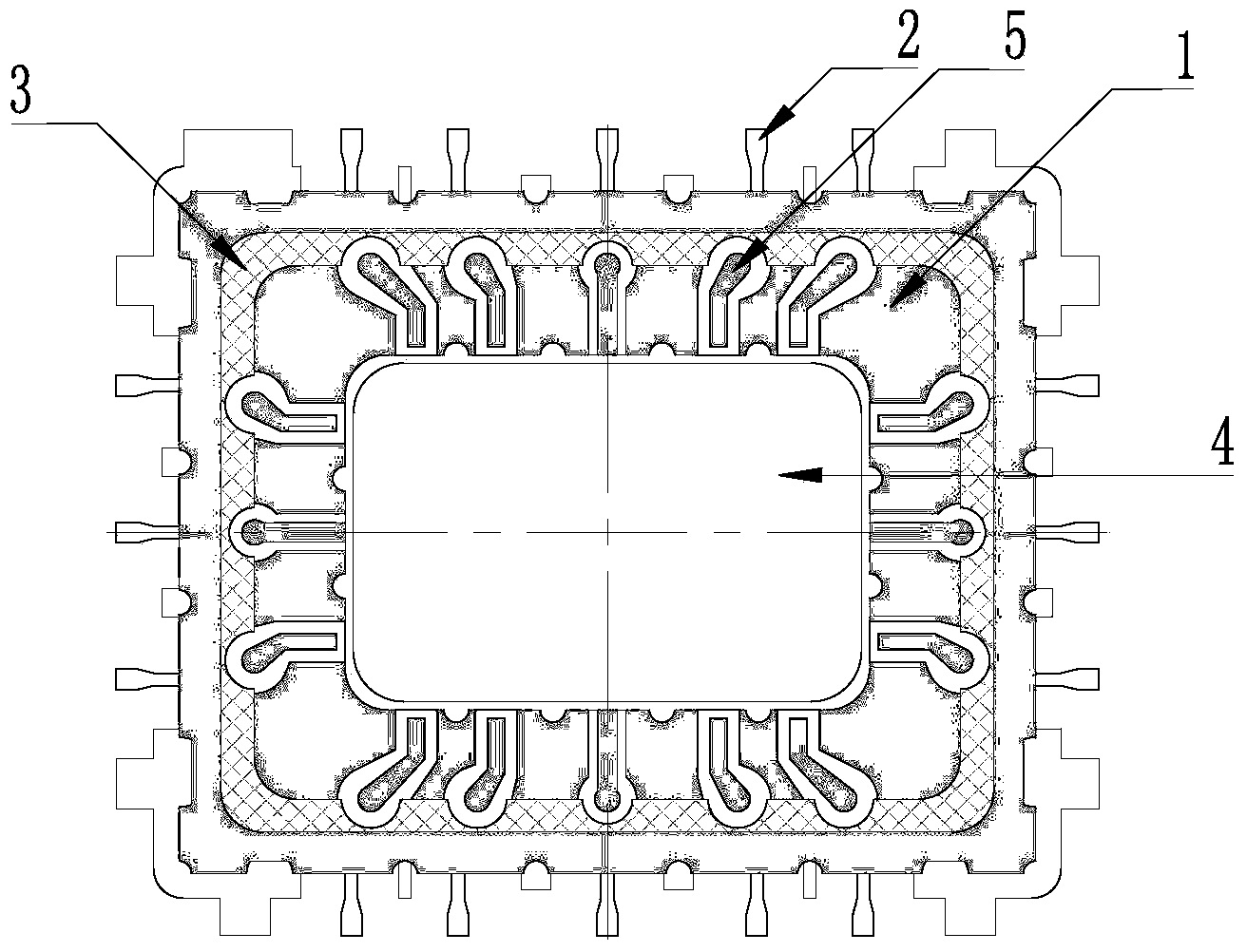

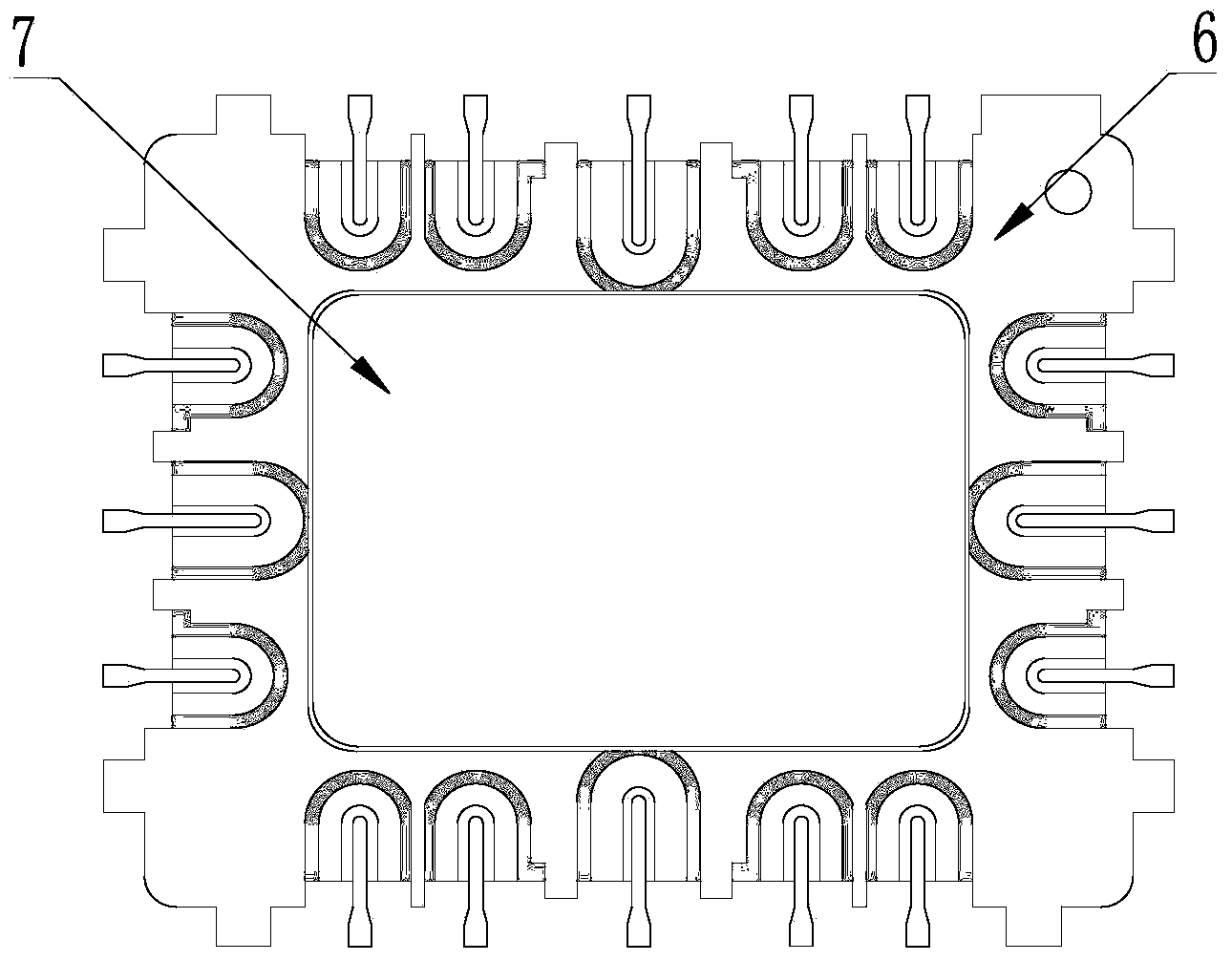

[0027] First refer to figure 1 and figure 2 The structure and outline drawing of the product, the molybdenum-copper gasket with the outline size of 6.05mm*4.10mm*0.35mm, the molybdenum-copper base of 7.13mm*5.18mm*0.15mm and the possible cutting leads. Routine cleaning is carried out to the above-mentioned metal parts, and they are used after nickel plating.

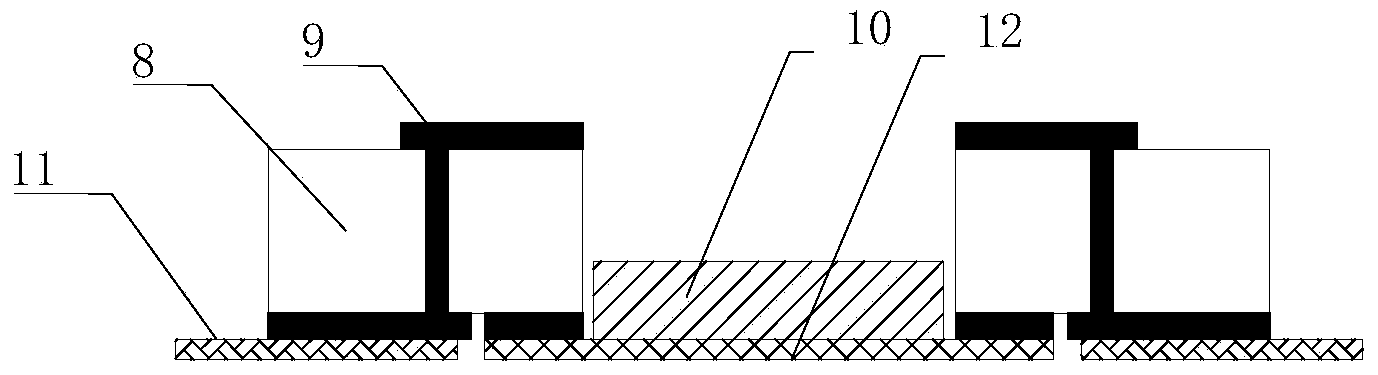

[0028] Second, follow the Figure 5 In the HTCC process shown, the taped raw ceramic tape made of special low-loss ceramic material is used to produce alumina ceramics with a size of 10.21mm*8.25mm*0.5mm, and the internal wiring meets the requirements, and it is nickel-plated for use.

[0029] then follow figure 1 , 2 As shown, the nickel-plated Kovar lead and the molybdenum-copper base are welded to the back of the ceramic part by Ag-Cu solder at a high temperature of about 800 ° C, and then the molybdenum-copper gasket is welded to the front side under the same conditions. in the lumen.

[0030] The above-menti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com