Lithium battery, lithium battery cathode material and manufacturing method thereof

A cathode material, lithium battery technology, applied in the field of electrochemistry, can solve the problems of poor rate performance and cycle performance, low discharge capacity, etc., and achieve the effect of good rate performance, cycle performance, and high discharge capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

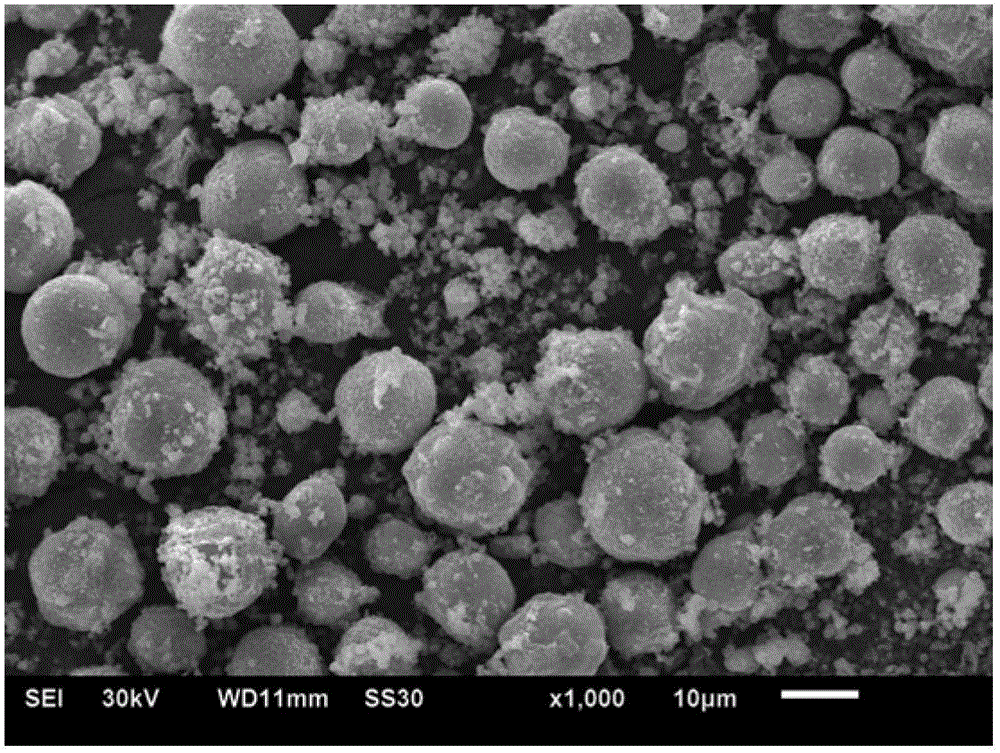

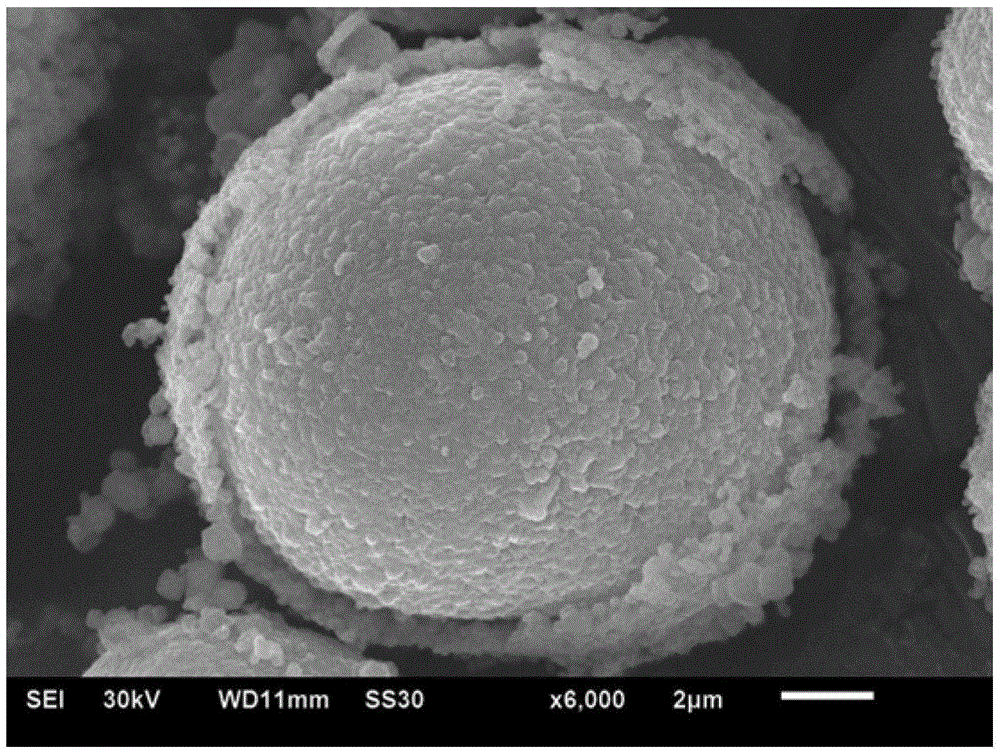

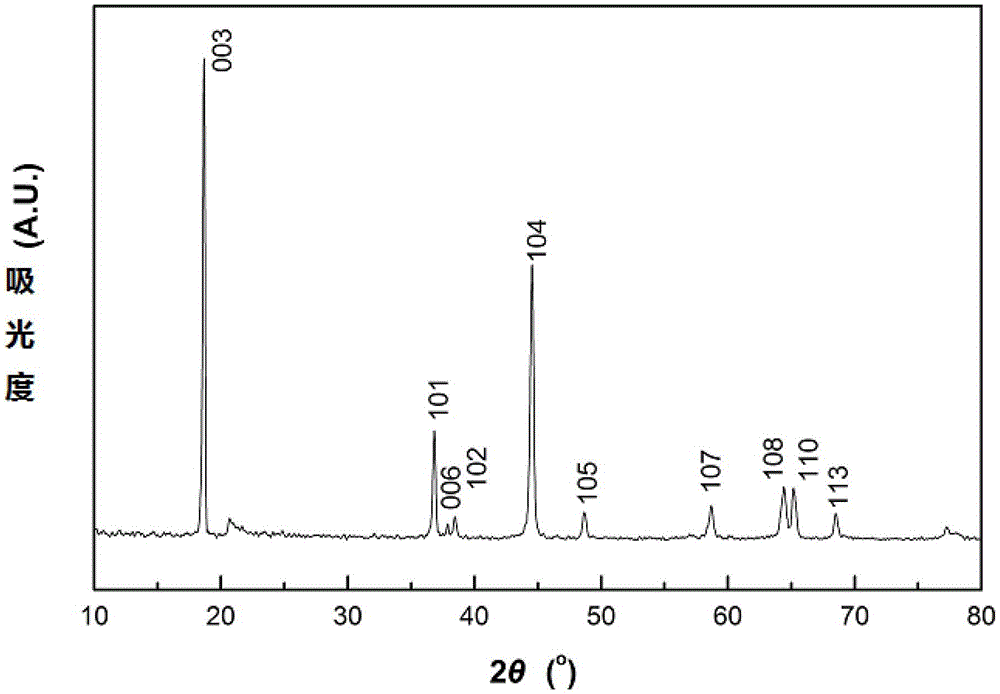

[0046] The lithium battery anode material that lithium battery adopts in the present embodiment is Li 1+a [Mn b (Mn x m 1-x ) 1-b ]O 2 ; Wherein: the value of a is 01+a [Mn b (Mn x m 1-x ) 1-b ]O 2 It is a spherical or quasi-spherical particle, and a single particle is composed of an inner core and an outer shell covering the inner core, the size of the particle is 2-20 μm, and the thickness of the outer shell is 5-2000 nm. See figure 1 and figure 2 The scanning electron microscope SEM image of the lithium battery positive electrode material shown; that is, the microscopic appearance of the positive electrode material prepared in this embodiment is spherical or spherical particles, and the spherical or spherical particles are composed of an inner core and an outer shell, forming a kind of The composite structure of the core and the shell can realize the complementary functions of the core and the shell through the synergistic effect of the core and the shell, so th...

Embodiment 2

[0051] In order to better understand the present invention, the present invention will be further described below in conjunction with a specific preparation method of the positive electrode material of a lithium battery; it should be understood that the positive electrode material in Example 1 is not limited to the following preparation method.

[0052] See Figure 8 As shown, the preparation method of lithium battery positive electrode material in the present embodiment comprises:

[0053] Step 801: Prepare spherical or spherical-like [Mn x m 1-x ](OH) 2 or [Mn x m 1-x ]CO 3 , which can also be referred to as the core material of the positive electrode material, wherein the M is at least one of Co, Ni, Al, Ti, Fe, Mg, Cr, and the value of x is 0≤x≤0.5;

[0054] Step 802: Prepare a lithium-containing Mn-based shell gel material, which can also be called the shell material of the positive electrode material; it is worth noting that there is no strict timing restriction be...

Embodiment 3

[0065] In this embodiment, nickel sulfate (NiSO 4 ·6H 2 O), manganese sulfate (MnSO 4 ·H 2 O), cobalt sulfate (NiSO 4 ·7H 2 O) prepare the core material as an example to illustrate, specifically as follows:

[0066] Step 1: nickel sulfate (NiSO 4 ·6H 2 O), manganese sulfate (MnSO 4 ·H 2 O), cobalt sulfate (NiSO 4 ·7H 2 O) Mix according to the ratio of Ni:Mn:Co (molar ratio)=1:1:1, dissolve in deionized water, and prepare a total metal ion concentration of 1.6mol / L (of course, it can also be configured as 0.1mol / L or 3.50.1mol / L) mixed salt solution A; 2 CO 3 Alkali solution and ammonia water with a concentration of 0.32mol / L;

[0067] Step 2: Add the mixed solution A into the reactor through a constant flow pump, Na 2 CO 3 Alkaline solution and ammonia water are respectively fed into the reaction kettle in parallel through a constant flow pump, and the stirring speed is controlled to be 1000rpm (or any other value between 50-1500rpm), and the reaction temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com