Preparation method of protein feed

A technology of protein feed and fermented raw materials, applied in animal feed, animal feed, application, etc., can solve the problem of high production cost, achieve the effect of low production conditions, improve nutrition, and promote rapid growth and development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

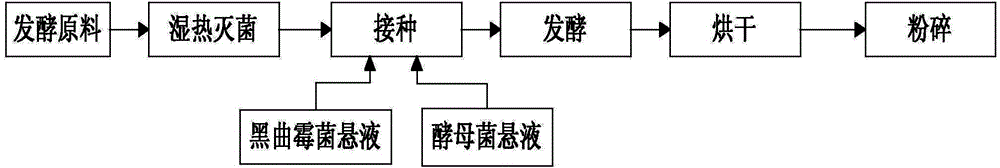

Method used

Image

Examples

Embodiment 1

[0030] The citrus pomace in this example is taken from Wenzhou satsuma.

[0031] 1) Raw material pretreatment: air half-dry 5Kg of citrus peels until the ignorant water is precipitated, remove mud, stones, bellflowers, leaves and other sundries, and then cut them into 1cm×1cm square blocks as fermentation raw materials;

[0032] Another 5Kg of citrus peels was air-dried until completely dry, and pulverized into a particle diameter of 40 mesh citrus peels powder as a raw material for Aspergillus niger fermentation.

[0033] 2) Cultivation of fermentation strains:

[0034] Cultivation of Aspergillus niger: Add 30g of citrus peel powder, 10g of bran, 15g of urea, 5g of (NH 4 ) 2 SO 4 , 5g of KH 2 PO 4 , 2g of MgSO 4 ·7H 2 0 and 1000mL sterile water, shake up, adjust the pH value to 6 with 0.35mol / L sodium hydroxide solution and / or 0.50mol / L hydrochloric acid solution to obtain the first fermentation raw material; after moist heat sterilization, insert Aspergillus niger for...

Embodiment 2

[0041] The citrus peel in the present embodiment is Jiangyong pomelo peel.

[0042] 1) Raw material pretreatment: Dry 5Kg of Jiangyong pomelo peel dregs in the air until the ignorant water precipitates out, remove mud, stones, platycodon grandiflora, leaves and other sundries, and then cut them into 1cm×1cm square blocks as fermentation raw materials;

[0043] Another 5 Kg of Jiangyong pomelo peel dregs were air-dried until completely dry, crushed into Jiangyong pomelo peel residue powder with a particle size of 40 mesh, and used as a raw material for Aspergillus niger fermentation.

[0044] 2) Cultivation of fermentation strains:

[0045] Cultivation of Aspergillus niger: Adding 30g particle diameter in the triangular flask is 40 mesh Jiangyong pomelo peel slag powder, 10g of bran, 15g of urea, 5g of (NH 4 ) 2 SO 4 , 5g of KH 2 PO 4 , 2g of MgSO 4 ·7H 2 0 and 1000mL sterile water, shake up, adjust the pH value to 6 with 0.35mol / L sodium hydroxide solution and / or 0.50mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com