TiAl/Ti3SiC2 composite plate material and preparation method thereof

A composite plate, a combined technology, applied in chemical instruments and methods, layered products, ceramic layered products, etc., can solve the problems of blank preparation methods, and achieve the effects of good diffusion ability, less impurities, and uniform performance distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

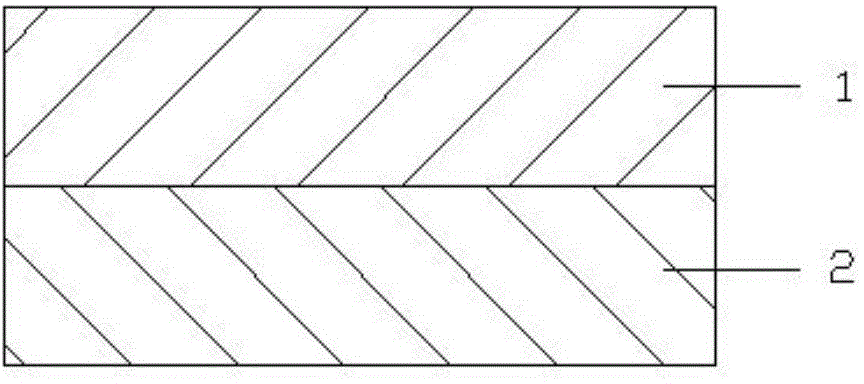

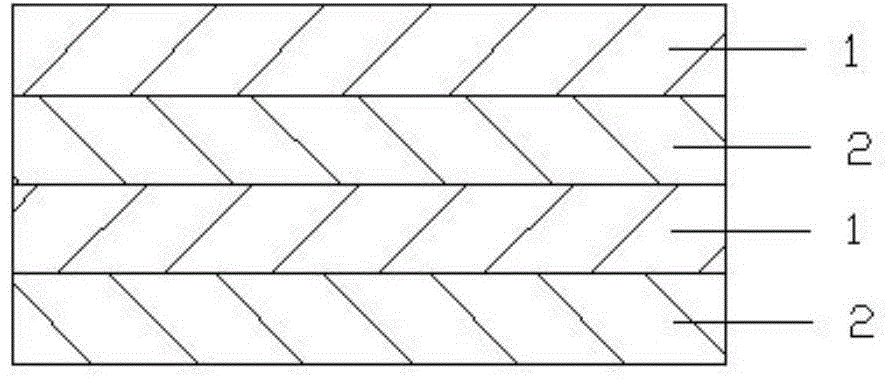

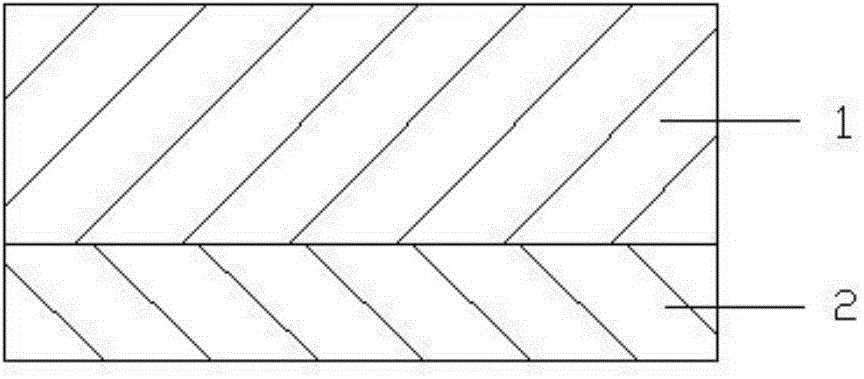

Image

Examples

Embodiment 1

[0026] Ti 3 SiC 2 The composition of the ceramic raw material powder is Ti, Si and C powder, wherein the molar percentage of Ti is 50%, the molar percentage of Si is 17%, and the molar percentage of C is 33%. The weighed powder is mixed with an appropriate amount of absolute ethanol, and then the mixture is placed on an electromagnetic stirring device for electromagnetic stirring. Stirring time is not less than 24 hours. After fully stirring, the mixture was put into a drying oven, and dried at 75° C. for 24 hours. After the powder is completely dry, take it out and put it into a Φ60mm graphite mold, use a tablet press to hold the pressure for 10 minutes under a pressure of 5MPa, and compact the powder to obtain Ti 3 SiC 2 The raw material of ceramics. The composition of the TiAl raw material powder is Ti powder and Al powder, wherein the mole percentage of Ti is 51%, and the mole percentage of Al is 49%. Mix the weighed powder with an appropriate amount of absolute etha...

Embodiment 2

[0035] (1) Ti 3 SiC 2 The composition of the ceramic raw material powder is Ti, Si and C powder, wherein the molar percentage of Ti is 50%, the molar percentage of Si is 17%, and the molar percentage of C is 33%. The weighed powder is mixed with an appropriate amount of absolute ethanol, and then the mixture is placed on an electromagnetic stirring device for electromagnetic stirring. Stirring time is not less than 24 hours. After fully stirring, the mixture was put into a drying oven, and dried at 75° C. for 24 hours. After the powder is completely dry, take it out and put it into a Φ60mm graphite mold, use a tablet press to hold the pressure for 10 minutes under a pressure of 5MPa, and compact the powder to obtain Ti 3 SiC 2 The raw material of ceramics. (2) The composition of the TiAl raw material powder is Ti powder and Al powder, wherein the molar percentage of Ti is 51%, and the molar percentage of Al is 49%. Mix the weighed powder with an appropriate amount of abs...

Embodiment 3

[0044] Ti 3 SiC 2 The composition of the ceramic raw material powder is Ti, Si and C powder, wherein the molar percentage of Ti is 50%, the molar percentage of Si is 17%, and the molar percentage of C is 33%. The weighed powder is mixed with an appropriate amount of absolute ethanol, and then the mixture is placed on an electromagnetic stirring device for electromagnetic stirring. Stirring time is not less than 24 hours. After fully stirring, the mixture was put into a drying oven, and dried at 75° C. for 24 hours. After the powder is completely dry, take it out and put it into a Φ60mm graphite mold, use a tablet press to hold the pressure for 10 minutes under a pressure of 5MPa, and compact the powder to obtain Ti 3 SiC 2 The raw material of ceramics. The composition of the TiAl raw material powder is Ti powder and Al powder, wherein the molar percentage of Ti is 51%, and the molar percentage of Al is 49%. Mix the weighed powder with an appropriate amount of absolute et...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com