A kind of preparation method of hexagonal boron nitride nanosheet

A hexagonal boron nitride and nanosheet technology, applied in chemical instruments and methods, nanotechnology, nanotechnology, etc., can solve problems such as lowering synthesis temperature, and achieve the effects of improving crystallinity, reducing energy consumption, and uniform size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

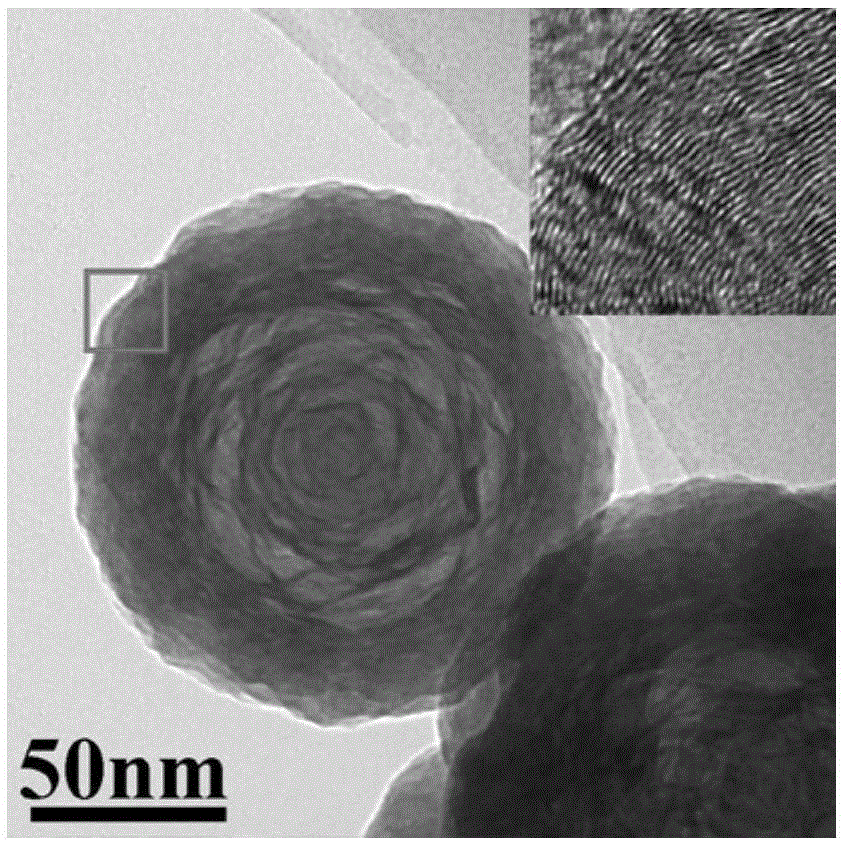

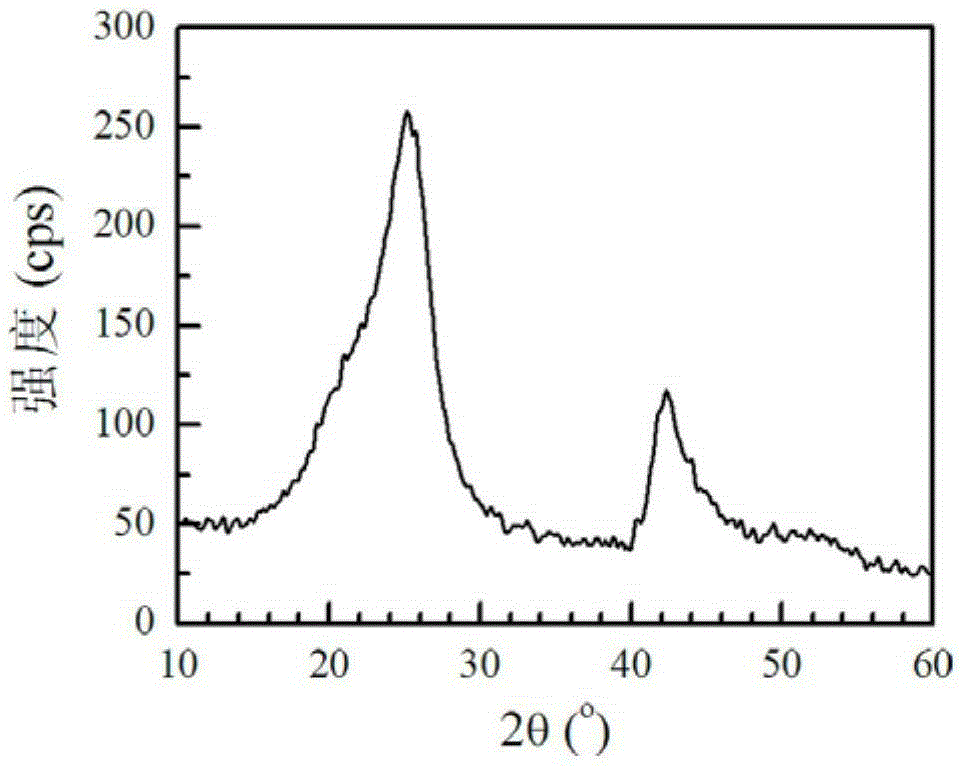

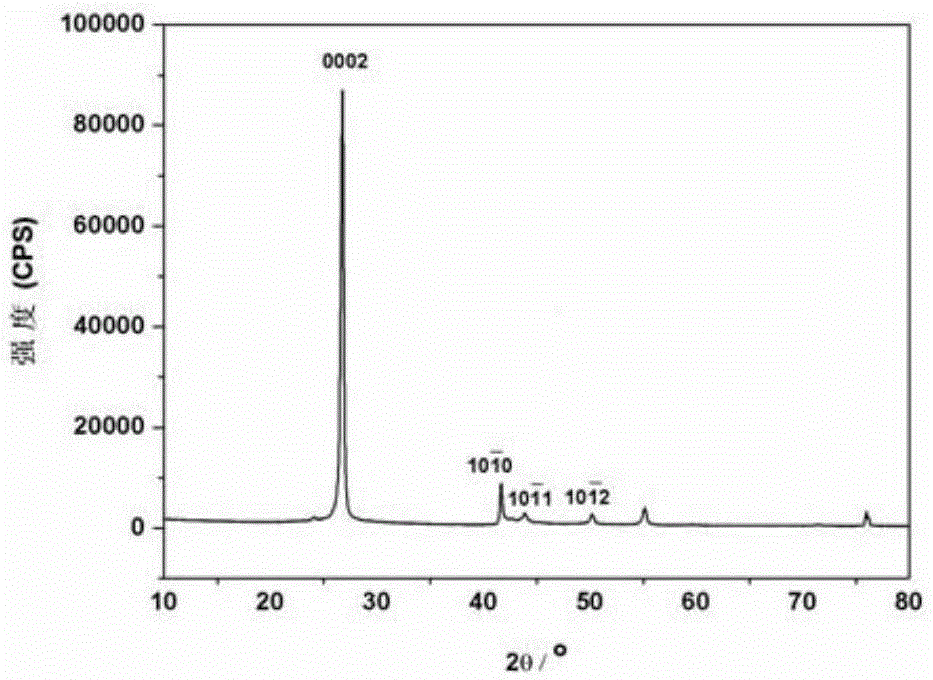

[0025] (1) Mix 1 gram of boron nitride balls with a particle size of about 100 nanometers and 1 gram of sodium chloride, and then stir the mixture for 1 hour at a speed of 1000 revolutions per minute; wherein, boron nitride nanospheres are used by Tang Chengchun and others. Chemical vapor deposition method, boron nitride material with onion sheet structure prepared from methyl borate and ammonia (C.C.Tang, Y.Bando, Y.Huang, C.Y.Zhi, D.Golberg, Adv.Func.Mater .,2008,18,3653-3661.), its microstructure is as figure 1 shown.

[0026] (2) The powder obtained in the step (1) is heat-treated under a nitrogen atmosphere. The technical route is as follows: the heat treatment temperature is 700°C, the heating rate is 10°C per minute, the holding time is 2 hours, the gas flow rate is 100 ml / min, and the temperature is lowered to room temperature in a nitrogen atmosphere. After the samples were taken out, they were washed with deionized water to remove excess metal chlorides. Then dry ...

Embodiment 2、 example 3、 example 4

[0029] Change the consumption of step (1) sodium chloride into 0.01 gram, 5 gram, 10 gram respectively in embodiment 1, other each operation is all identical with embodiment 1, obtains product with embodiment 1.

Embodiment 5、 example 6、 example 7、 example 8、 example 9、 example 10、 example 11、 example 12、 example 13

[0031] Step (2) metal chloride in embodiment 1 is respectively changed into lithium chloride, potassium chloride, calcium chloride, magnesium chloride, aluminum chloride, ferric chloride, ferrous chloride, zinc chloride, cupric chloride, Other operations are the same as in Example 1, and the product obtained is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com