A safe production process for large-scale production of high-purity phosphine trihydrogen

A phosphorous trihydride, safe production technology, applied in sustainable manufacturing/processing, chemical industry, phosphine, etc., to reduce the entry of impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

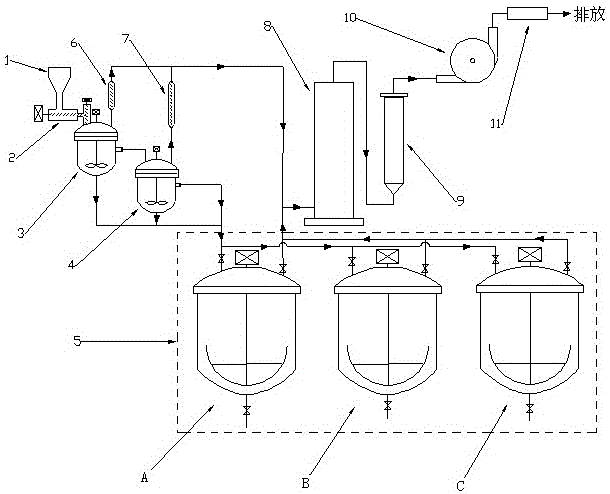

[0031] A safe production process for large-scale production of high-purity phosphine trihydrogen, using aluminum phosphide and deionized water as raw materials, under closed reaction conditions, using sealed solid feed, negative pressure three-stage series reactor reaction, low temperature and low pressure Capture and purification, tail gas oxidation to remove trivalent phosphorus, and lye and activated carbon to absorb phosphorus pentoxide. The specific realization of the process is as follows: figure 1 As shown, it is a flow chart of a safe production process for large-scale production of high-purity phosphine trihydrogen, including a hopper 1, a screw solid feeder 2, a first-stage reactor 3, a second-stage reactor 4, and a third-stage reactor 5. The first condensing reflux device 6, the second condensing reflux device 7, the low-temperature and low-pressure trapping purifier 8, the absorber 9, the vacuum pump 10 and the catalytic oxidizer 11; wherein the bottom of the hopper ...

Embodiment 2

[0076]The safety production process device of large-scale manufacture of high-purity phosphine trihydrogen in Example 1 is used to prepare phosphine trihydrogen, and the vacuum degree of the control three-stage series reactor is 100-200mmHg, wherein the first-stage reactor 3, the second-stage reaction The temperature of the reactor 4 is 40-45°C, the temperature of the third-stage reactor 5 is 25°C, and the operating condition of the low-temperature and low-pressure trapping purifier 8 is an operating pressure of 100-200mmHg; operating temperature: purifier: -50°C; receiver : -95°C; trap: -160°C, other control conditions are the same as in Example 1. The yield of solid phosphine trihydrogen trapped by the cryogenic trap is calculated by the same method as in Example 1: between 86-90% (weight).

Embodiment 3

[0078] Adopt the safety production process device of large-scale preparation of phosphine trihydrogen of embodiment 1 to prepare phosphine trihydrogen, control the vacuum degree of the three-stage series reactor to be 500-600mmHg, wherein the first-stage reactor 3, the second-stage reactor 4 The temperature is 45-55°C, the temperature of the third-stage reactor 5 is 25°C, and the operating condition of the low-temperature and low-pressure trapping purifier 8 is an operating pressure of 500-600mmHg; operating temperature: purifier: -55°C; receiver: - 100°C; trap: -155°C, other control conditions are the same as in Example 1. The yield of the solid-state phosphorus trihydride trapped by the cryogenic trap is calculated by the same method as in Example 1: between 88-91% (weight).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com