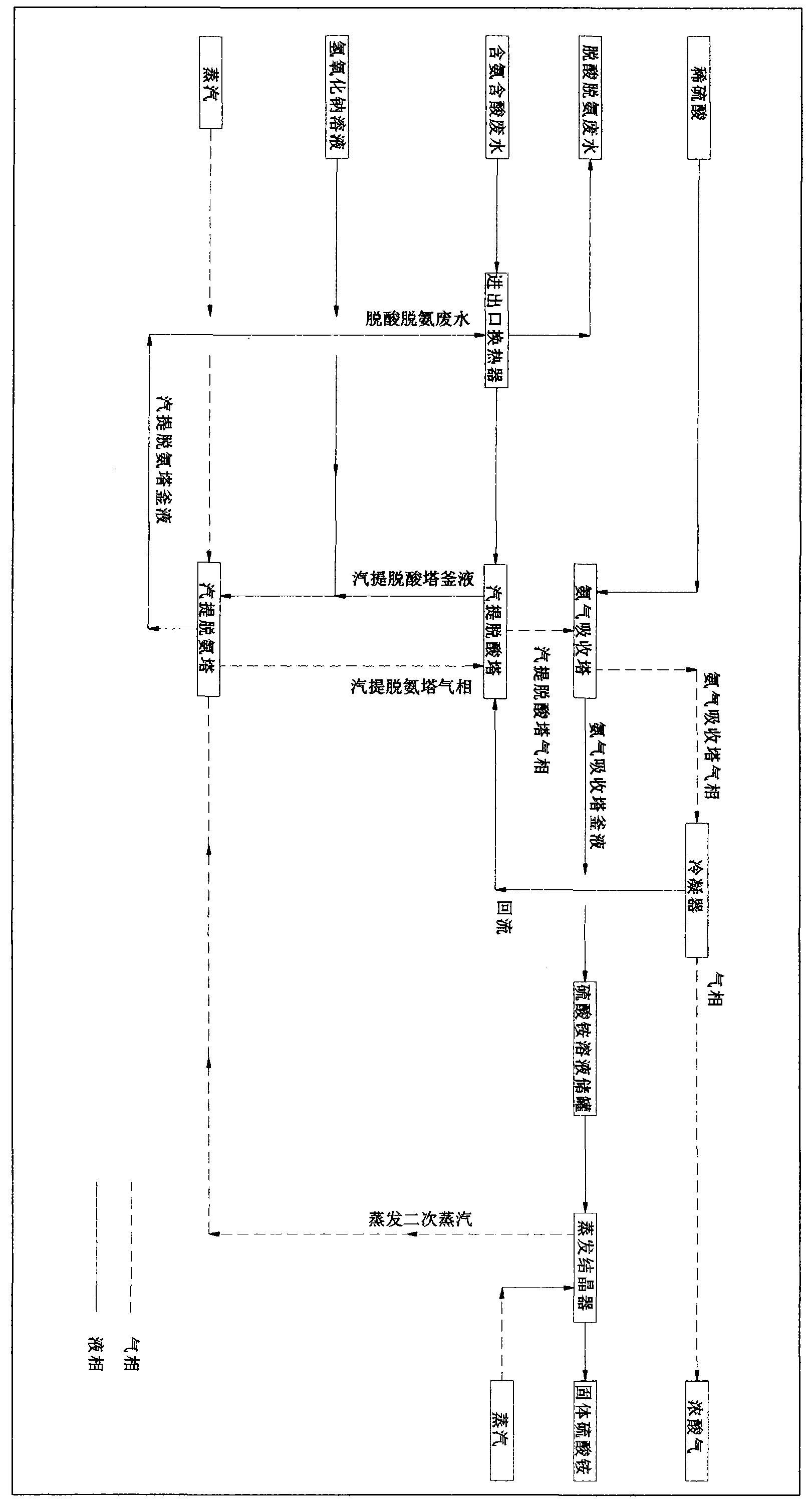

Technology method for steam stripping deacidification and deamination of waste water

A technology for stripping and deammonia and a process method is applied in the field of industrial wastewater emission reduction and resource utilization, and can solve the problems of narrow ammonia nitrogen treatment range, effluent ammonia nitrogen concentration not reaching the national first-class emission standard, and high energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Using the present invention to treat ammonia-containing and acid-containing waste water, the imported ammonia nitrogen concentration is 1800mg / L, the sulfide concentration is 780mg / L, and the treatment capacity is 1m 3 / h. Using Nessler's reagent colorimetric method (GB7479-87) and methylene blue spectrophotometry (GB / T16489-1996) analysis, the ammonia nitrogen concentration in the treated wastewater is 2.7mg / L, the hydrogen sulfide content is 5mg / L, and the steam consumption It is 132kg / ton of waste water.

Embodiment 2

[0033] Using the present invention to treat ammonia-containing and acid-containing waste water, the imported ammonia nitrogen concentration is 10100mg / L, the sulfide concentration is 6400mg / L, and the treatment capacity is 120m 3 / h. Using Nessler's reagent colorimetric method (GB7479-87,) and methylene blue spectrophotometry (GB / T16489-1996) analysis, the ammonia nitrogen concentration in the treated wastewater is 8.0mg / L, the hydrogen sulfide content is 14mg / L, and the steam consumption The amount is 120kg / ton of waste water.

Embodiment 3

[0035] Using the present invention to treat ammonia-containing and acid-containing wastewater, the imported ammonia nitrogen concentration is 38300 mg / L, the sulfide concentration is 1500 mg / L, and the treatment capacity is 30 3 / h. Using Nessler's reagent colorimetry (GB7479-87) and methylene blue spectrophotometry (GB / T16489-1996) analysis, the ammonia nitrogen concentration in the treated wastewater is 6.5mg / L, the hydrogen sulfide content is 13mg / L, and the steam consumption It is 126kg / ton of waste water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com