A2O2-MBR sewage treatment process and device

A sewage treatment device and technology for sewage treatment, applied in water/sewage multi-stage treatment, oxidized water/sewage treatment, water/sludge/sewage treatment, etc. The efficiency cannot be further improved, and the area of the secondary sedimentation tank is large, so as to reduce the sludge production, improve the sludge-water separation effect, and improve the effluent quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

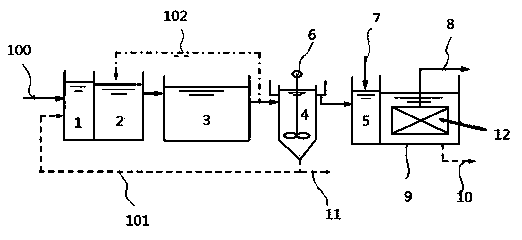

[0033] figure 1 The reference numbers in the drawings are: sewage input pipe 100; sludge return pipe 101; internal circulation pipe 102; anaerobic pool 1; anoxic pool 2; aerobic pool 3; sedimentation tank 4; ozone pre-oxidation zone 5; agitator 6. Ozone water input pipeline 7; drain pipe 8; MBR reaction tank 9; second excess sludge discharge pipe 10; first excess sludge discharge pipe 11; cross MBR membrane module 12;

[0034] The invention needs to solve the problems that the treatment efficiency of the traditional AAO process cannot be further improved, the occupied area is large, the concentration of suspended solids in the effluent after precipitation is high, and the sludge output is high. A new wastewater treatment process suitable for the upgrading and transformation of the AAO process is proposed, which can make full use of the advanta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com