System and method for treating slightly alkaline secondary effluent through magnetic ion exchange resin coupled catalytic ozonation circulating reflux

An exchange resin, ozone oxidation technology, applied in ion exchange water/sewage treatment, chemical instruments and methods, oxidized water/sewage treatment, etc. The effect of small equipment footprint, increased water treatment volume, and improved treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

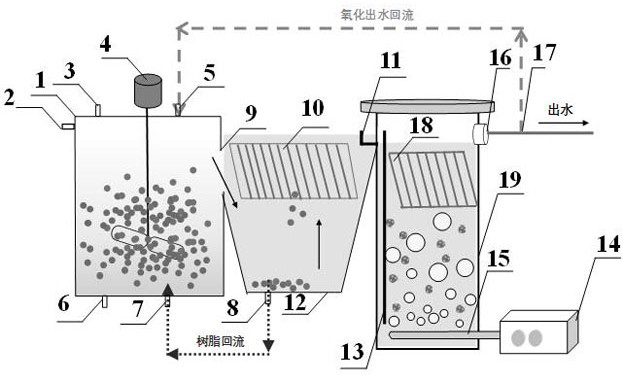

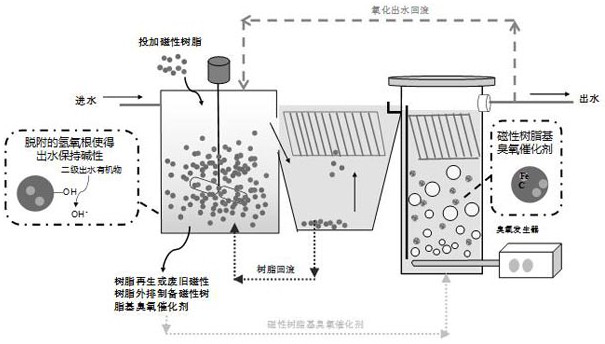

[0040] The slightly alkaline secondary effluent (pH=7~9) that meets the first-level A standard of "GB 18918-2002 Pollutant Discharge Standard for Urban Sewage Treatment Plants" is injected into the high-density resin mixing tank 1 through the water inlet 2, and the magnetic resin passes through The regenerated resin enters the high-density resin mixing pool 1 through the inlet 3, and the magnetic resin is stirred and mixed with the secondary effluent by the mechanical stirrer 4, and the secondary effluent is treated with the magnetic resin. The magnetic resin is a spherical magnetic acrylic anion resin with a diameter of 180 microns to 200 microns, the resin is chlorine type and hydroxide type, and the high-density resin mixing tank 1 is filled with a volume ratio of 60%, and the regeneration solution of the resin It is a mixed regeneration solution of sodium chloride and sodium hydroxide. When the resin needs to be regenerated or the waste resin is used to prepare a catalyst,...

Embodiment 2

[0042] The slightly alkaline secondary effluent (pH=7~9) that meets the first-level A standard of "GB 18918-2002 Pollutant Discharge Standard for Urban Sewage Treatment Plants" is injected into the high-density resin mixing tank 1 through the water inlet 2, and the magnetic resin passes through The regenerated resin enters the high-density resin mixing pool 1 through the inlet 3, and the magnetic resin is stirred and mixed with the secondary effluent by the mechanical stirrer 4, and the secondary effluent is treated with the magnetic resin. The magnetic resin is a spherical magnetic acrylic anion resin and a magnetic acrylic cation resin with a diameter of 100 microns to 200 microns, the resins are sodium type, chlorine type and hydroxide radical type, and the filling volume ratio of the high-density resin mixing pool is 60%, the proportion of the two resins is 80% for anion and 20% for cation, and the regeneration liquid of the magnetic resin is a mixed regeneration liquid of ...

Embodiment 3

[0044]The slightly alkaline secondary effluent (pH=7~9) that meets the "GB 18918-2002 Pollutant Discharge Standard for Urban Sewage Treatment Plants" Class I B standard is injected into the high-density resin mixing tank 1 through the water inlet 2, and the magnetic resin passes through The regenerated resin enters the high-density resin mixing pool 1 through the inlet 3, and the magnetic resin is stirred and mixed with the secondary effluent by the mechanical stirrer 4, and the secondary effluent is treated with the magnetic resin. Described magnetic resin diameter is the spherical magnetic styrene series anion resin of 50 microns to 300 microns, magnetic acrylic series cationic resin and magnetic phenolic series amphoteric ion exchange resin, and magnetic resin is sodium type, chlorine type and hydroxide radical type, The filling volume ratio of the high-density resin mixing pool is 70%, the ratio of the three resins is 70% for anion, 20% for cation, and 10% for amphoteric io...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com