Method for producing foam microcrystal thermal insulating decoration board by use of fluorite tailings

A technology of thermal insulation decorative panels and fluorite tailings, which is applied in the field of inorganic non-metallic materials, can solve environmental pollution, safety and other problems, and achieve significant economic benefits, huge economic benefits, and smooth surfaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

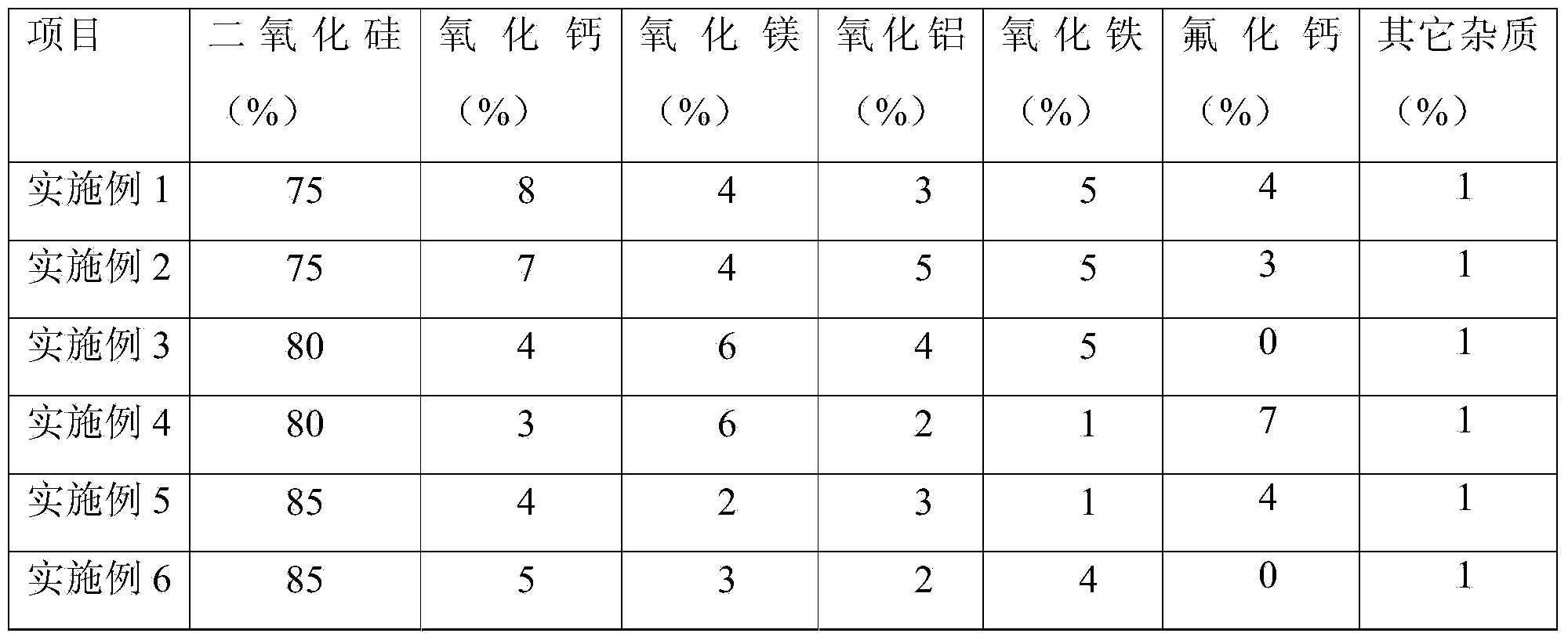

Embodiment 1

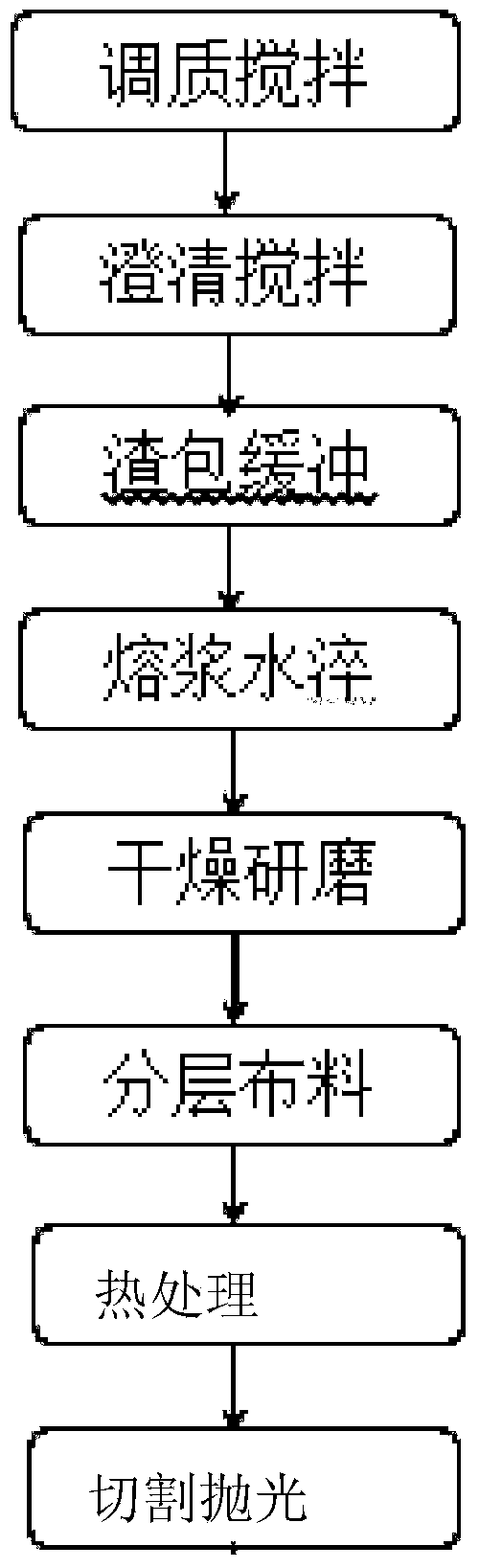

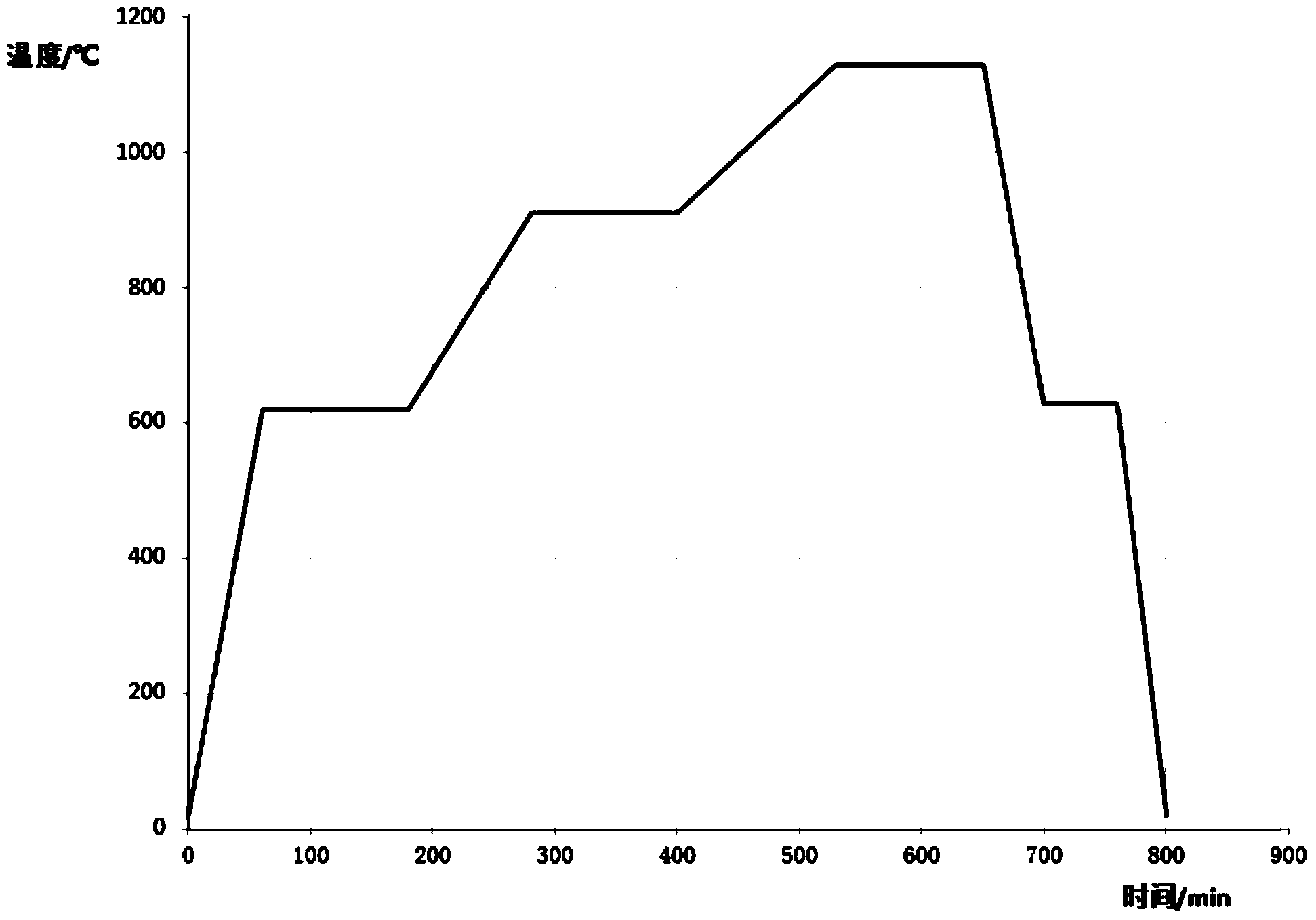

[0067] The present invention provides a process for producing foamed microcrystalline thermal insulation decorative panels using fluorite tailings, comprising the following steps:

[0068] (1) Melt the fluorite tailings at high temperature, add modifiers and clarifiers, stir evenly to ensure the melting temperature, the melting temperature is 1500-1550°C, and keep warm for 2 hours;

[0069] (2) The fluorite tailings lava enters the intermediate buffer bag from the molten pool first, and then flows into the water quenching pool from the lower nozzle of the buffer bag for water quenching treatment to form glass particles;

[0070] (3) After the obtained glass-ceramics raw material is ground, screen out glass-ceramic pellets and glass-ceramics powder, add foaming agent calcium carbonate and 1% foaming agent accounting for 2% of the powder mass in the glass-ceramics powder The foam stabilizer borax and fully mixed to obtain a glass-ceramic mixture. The particle size of the glass-...

Embodiment 2

[0076] The present invention provides a process for producing foamed microcrystalline thermal insulation decorative panels using fluorite tailings, comprising the following steps:

[0077] (1) Melt the fluorite tailings at high temperature, add modifiers and clarifiers, stir evenly to ensure the melting temperature, the melting temperature is 1500-1550°C, and keep warm for 2 hours;

[0078] (2) The fluorite tailings lava enters the intermediate buffer bag from the molten pool first, and then flows into the water quenching pool from the lower nozzle of the buffer bag for water quenching treatment to form glass particles;

[0079] (3) After the obtained glass-ceramics raw material is ground, screen out glass-ceramic pellets and glass-ceramics powder, add foaming agent calcium carbonate and 1% foaming agent accounting for 2% of the powder mass in the glass-ceramics powder The foam stabilizer borax and fully mixed to obtain a glass-ceramic mixture. The particle size of the glass-...

Embodiment 3

[0085] The present invention provides a process for producing foamed microcrystalline thermal insulation decorative panels using fluorite tailings, comprising the following steps:

[0086] (1) Melt the fluorite tailings at high temperature, add modifiers and clarifiers, stir evenly to ensure the melting temperature, the melting temperature is 1500-1550°C, and keep warm for 2 hours;

[0087] (2) The fluorite tailings lava enters the intermediate buffer bag from the molten pool first, and then flows into the water quenching pool from the lower nozzle of the buffer bag for water quenching treatment to form glass particles;

[0088] (3) After the obtained glass-ceramics raw material is ground, screen out glass-ceramic pellets and glass-ceramics powder, add foaming agent calcium carbonate and 1% foaming agent accounting for 2% of the powder mass in the glass-ceramics powder The foam stabilizer borax and fully mixed to obtain a glass-ceramic mixture. The particle size of the glass-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com