Method for separating cis and trans carboxylic acids from mixed acids with cis and trans carboxylic acid isomers

An isomer and mixed acid technology, applied in the field of separating cis carboxylic acid and trans carboxylic acid, can solve the problems of difficulty in large-scale production and only use, and achieves high production cost, simple production process and low production cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

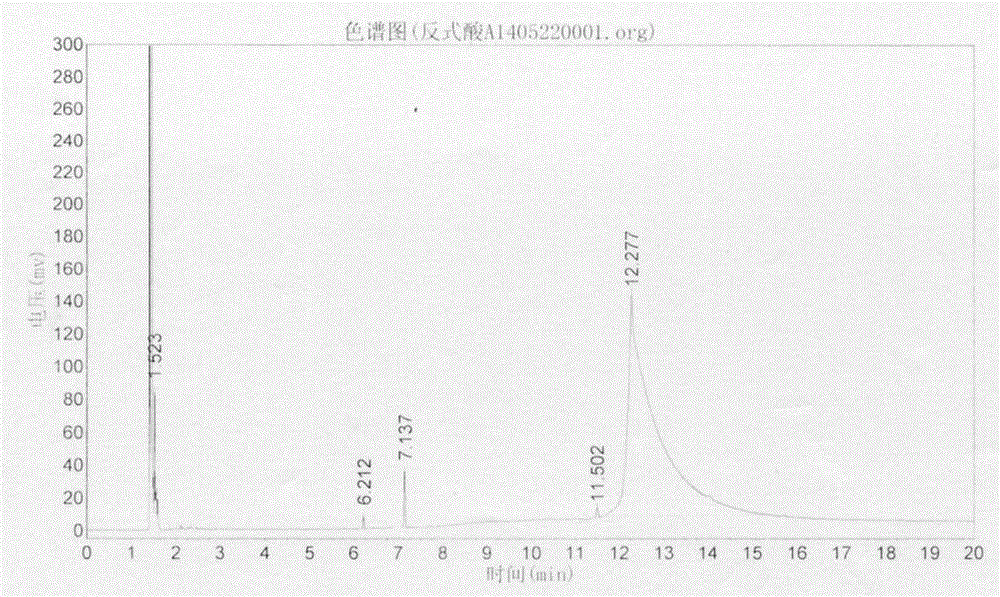

example 1

[0023] Add 250ml of anhydrous ether to a 500ml dry three-necked flask (equipped with a stirrer, thermometer, calcium chloride drying tube, and ventilation tube), add 50g of 11-methoxy-3,7,11-trimethyl-2, 4E-diene dodecanoic acid (a mixture of cis-acid and trans-acid), stir to dissolve, nitrogen gas is introduced into the vent pipe, ice-salt bath, the temperature of the material liquid is lowered to -5°C, and the vent pipe is changed to dry ammonia , the mass of ammonia gas introduced is 35.0g, and the process temperature cannot exceed 5°C. Keep stirring at -5~-2°C for 2 hours. Filter while cold to obtain filter cake and filtrate A. The filter cake was slurried with 50ml of cold diethyl ether and then filtered, and dried as much as possible by suction to obtain 35g of wet product and filtrate B. Put the wet product in a 500ml beaker, add 150ml of n-hexane and 50ml of water, stir to dissolve, adjust the pH of the solution to ≤1 with 20% sulfuric acid solution, let it stand for...

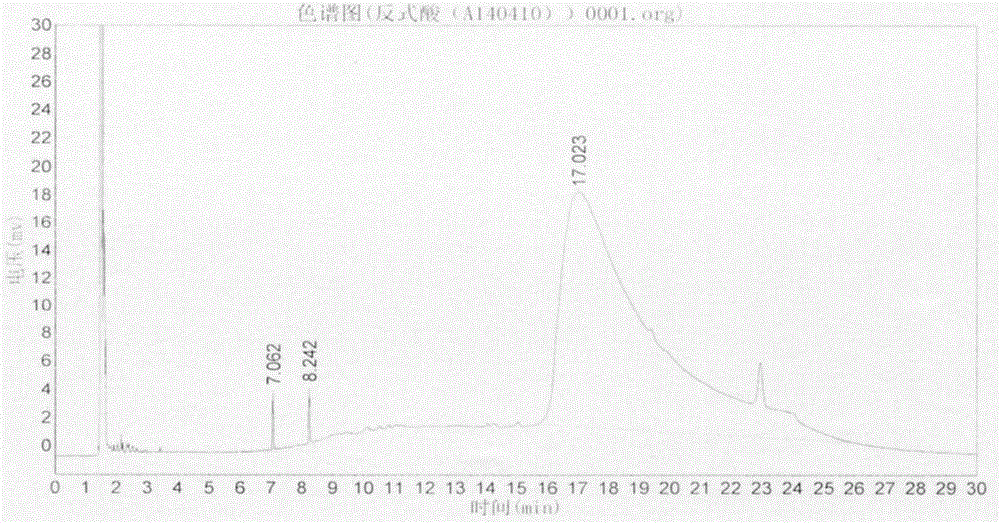

example 2

[0025] Add 250ml of anhydrous n-hexane to a 500ml dry three-neck flask (equipped with a stirrer, thermometer, calcium chloride drying tube, vent tube), and add 50g of 11-methoxy-3,7,11-trimethyl-2 , 4E-diene dodecanoic acid (a mixture of cis-acid and trans-acid), stir to dissolve, nitrogen gas into the vent pipe, ice-salt bath, the temperature of the material liquid is reduced to -5 ° C, the vent pipe is changed to dry ammonia Gas, the quality of passing through the ammonia gas is 35.0g, and the process temperature cannot exceed 5°C. Keep stirring at -5~-2°C for 2 hours. Filter while cold, wait until the filter cake and filtrate A. The filter cake was slurried with 50ml of cold n-hexane and then filtered, and dried as much as possible by suction to obtain 38g of wet product and filtrate B. Put the wet product in a 500ml beaker, add 150ml of n-hexane and 50ml of water, stir to dissolve, adjust the pH of the solution to ≤1 with 20% sulfuric acid solution, let it stand for 30 m...

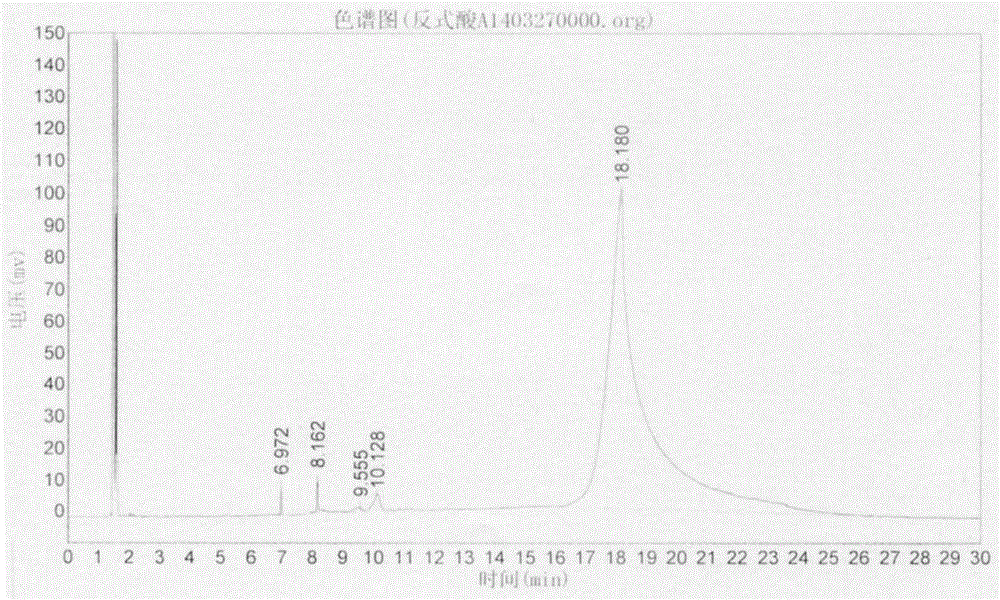

example 3

[0027]Add 250ml of anhydrous toluene to a 500ml dry three-necked flask (equipped with stirrer, thermometer, calcium chloride drying tube, vent tube), add 50g11-methoxyl-3,7,11-trimethyl-2, 4E-diene dodecanoic acid (a mixture of cis-acid and trans-acid), stir to dissolve, nitrogen gas is introduced into the vent pipe, ice-salt bath, the temperature of the material liquid is lowered to -5°C, and the vent pipe is changed to dry ammonia , the mass of ammonia gas introduced is 35.0g, and the process temperature cannot exceed 5°C. Keep stirring at -5~-2°C for 2 hours. Filter while cold, wait until the filter cake and filtrate A. The filter cake was slurried with 50ml of cold toluene and then filtered, and dried as much as possible to obtain 40.5g of wet product and filtrate B. Put the wet product in a 500ml beaker, add 150ml of n-hexane and 50ml of water, stir to dissolve, adjust the pH of the solution to ≤1 with 20% sulfuric acid solution, let it stand for 30 minutes, separate th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com