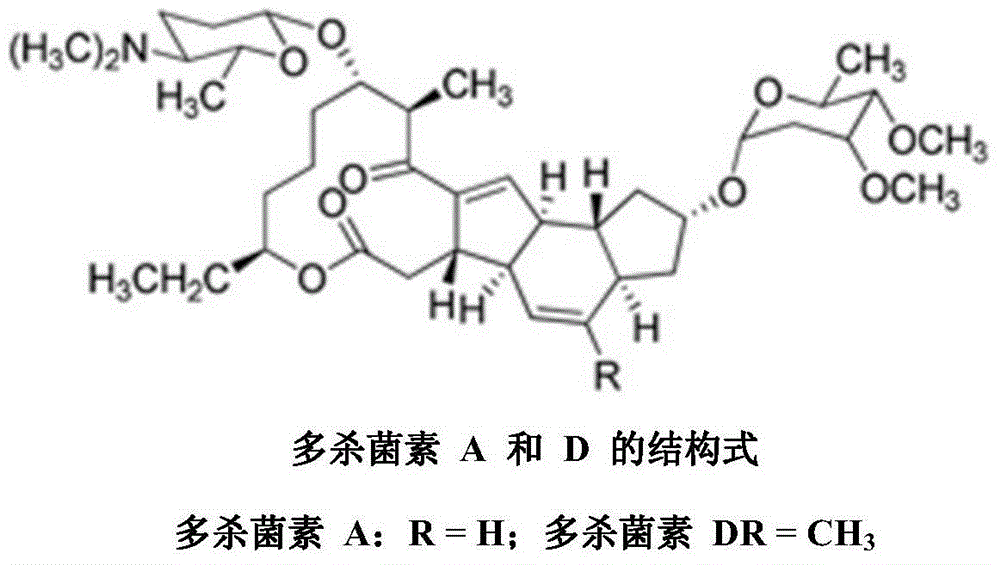

Method for extracting pleocidin from saccharopolyspora spinosa fermentation liquor

A technology of Saccharopolyspora spinosa and spinosad, which is applied in the field of spinosad extraction, can solve the problems of serious environmental pollution, high difficulty in wastewater treatment, and large usage, so as to achieve safe operation, reduce the difficulty of wastewater treatment, and reduce the The effect of usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

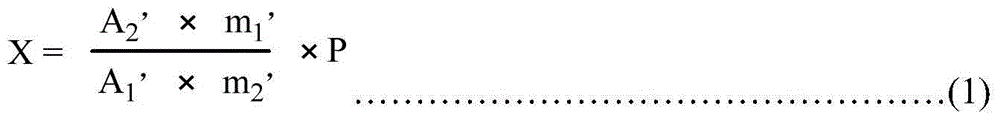

[0024] ①Add 1000mL of fermentation broth (containing 0.56g of spinosad) to the alkalization kettle, adjust the pH of the fermentation broth to 9 with 30% NaOH solution, stir at room temperature for 30 minutes and centrifuge to obtain 52g of solid; ②Add to the water phase after one centrifugation 50g of bentonite, stirred at room temperature for 30min, centrifuged to obtain 56g of solid, and the second centrifuge liquid was sent to waste water for treatment; ③Combine the solid after the first and second centrifugation, and dry it under vacuum (1.33kPa) at 50°C for 5h to obtain 93g of dry solid; ④Use cable 186g n-pentane was added, refluxed for 3h; ⑤ under reduced pressure (1.33kPa) precipitation, adding 5g n-pentane recrystallization, to get 0.47g spinosad product, content 90.0% (liquid chromatography, external standard; Component A84.7%, component D5.3%), yield 76.2%.

Embodiment 2

[0026] ① Add 1000mL of fermentation broth (containing 0.56g of spinosad) to the alkalization kettle, adjust the pH of the fermentation broth to 8 with 20% NaOH solution, stir at room temperature for 15 minutes and then centrifuge to obtain 52g of solid; ② Add to the water phase after one centrifugation 50g of activated carbon was centrifuged at 5°C for 60min to obtain 58g of solid, and the second centrifuge was sent to waste water for treatment; ③Combine the solid after the first and second centrifugation, and dry it under vacuum (1.33kPa) at 30°C for 8h to obtain 92g of dry solid; ④Use Soxhlet extraction method, add 92g methanol, reflux 8h; ⑤ desolvation under reduced pressure (1.33kPa), add 5g cyclohexane recrystallization, get 0.71g spinosad product, content 75.0% (liquid chromatography, external standard; Component A70.7%, component D4.3%), yield 95.0%.

Embodiment 3

[0028] ①Add 1000mL of fermentation broth (containing 0.56g of spinosad) to the alkalization kettle, adjust the pH of the fermentation broth to 10 with 50% NaOH solution, stir at room temperature for 15 minutes and then centrifuge to obtain 53g of solid; ②Add to the water phase after one centrifugation 50g of macroporous resin was centrifuged at 50°C for 15 minutes to obtain 57g of solid, and the second centrifugal liquid was sent to waste water for treatment; ③Combine the solid after the first and second centrifugation, and dry it under vacuum (1.33kPa) at 80°C for 1 hour to obtain 91g of dry solid; 4. Adopt Soxhlet extraction method, add 455g ethanol, reflux 1h; 5.Desolvation under reduced pressure (1.33kPa), add 5g n-hexane recrystallization, get 0.47g spinosad product, content 84.0% (liquid chromatography, external standard; Component A79.1%, component D4.9%), yield 70.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com