Antihypertensive peptide P16 as well as preparation method and application thereof

A blood pressure-lowering peptide, P16 technology, applied in the field of peptides, can solve problems such as unstandardized product quality, achieve huge practical value and economic benefits, good blood pressure lowering effect, and the effect of inhibiting the activity of ACE enzymes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The amino acid sequence of the hypotensive peptide P16 provided in this example is shown in SEQ ID No.1.

[0031] The above-mentioned hypotensive peptide P16 is prepared by the following method:

[0032] (1) Add 4000mL of pure water to the beaker, stir at 200rpm, slowly add 1kg of casein (Fonterra food-grade imported casein, just listed, not limited to this) into the beaker, stir and dissolve at 40°C, Aqueous solution of casein;

[0033] (2) Adding trypsin to the aqueous solution of casein for enzymolysis, the enzymolysis conditions are: the amount of enzyme added is 0.1% of the total mass of casein, the reaction temperature is 40°C, the reaction time is 1h, and the pH is 7.0;

[0034] (3) Adjust the temperature to 80°C, keep it warm for 30 minutes, and sterilize;

[0035] (4) adjust the pH value to 4.0, and centrifuge at 3000r / min for 30min to remove unenzymolyzed macromolecular protein precipitates to obtain a supernatant containing highly active blood pressure-lowe...

Embodiment 2

[0058] The amino acid sequence of the hypotensive peptide P16 provided in this example is shown in SEQ ID No.1.

[0059] The above-mentioned high-purity hypotensive peptide P16 is prepared by the following method:

[0060] (1) Add 600mL of pure water to the beaker, stir at 200rpm, slowly put 100g of casein into the beaker, stir and dissolve at 50°C;

[0061] (2) Adding trypsin for enzymolysis, the enzymolysis conditions are: the amount of enzyme added is 0.2% of the casein mass, the reaction temperature is 50°C, the reaction time is 2h, and the pH is 9.0;

[0062] (3) Adjust the temperature to 90°C, keep it warm for 20 minutes, and inactivate the enzyme;

[0063] (4) adjust the pH value to 5.0, and centrifuge at 5000r / min for 20min to remove unenzymolyzed macromolecular protein precipitates;

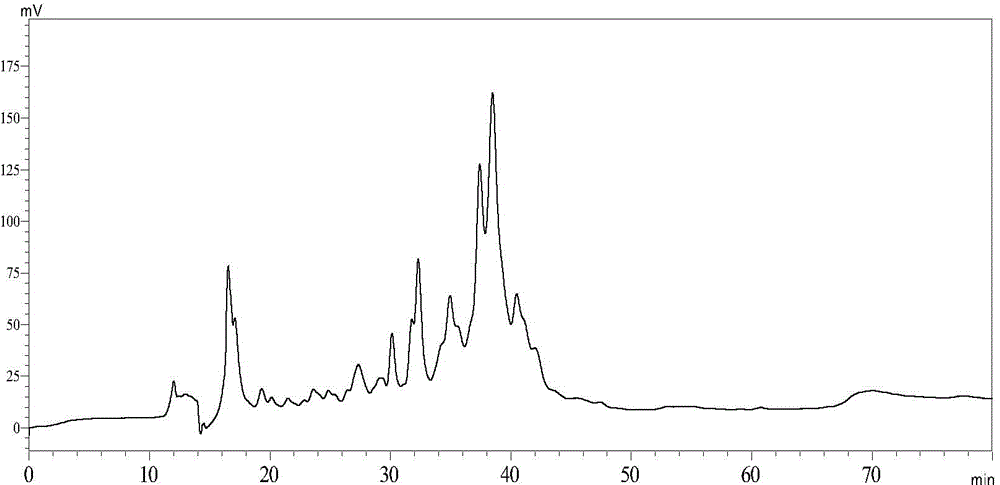

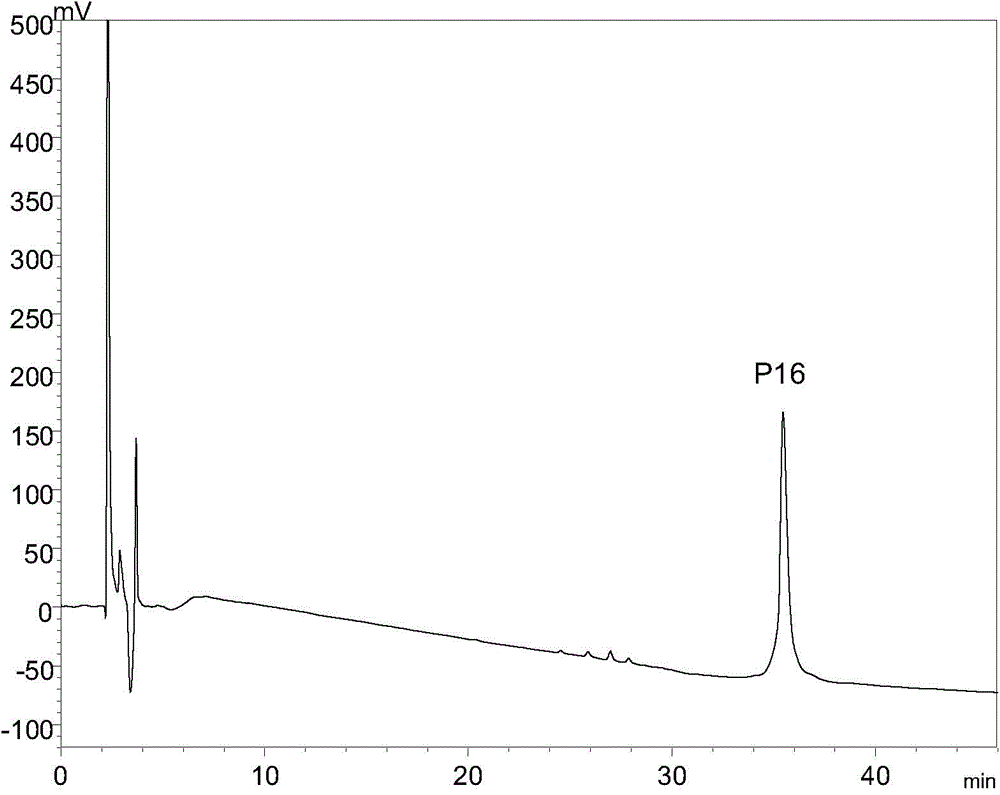

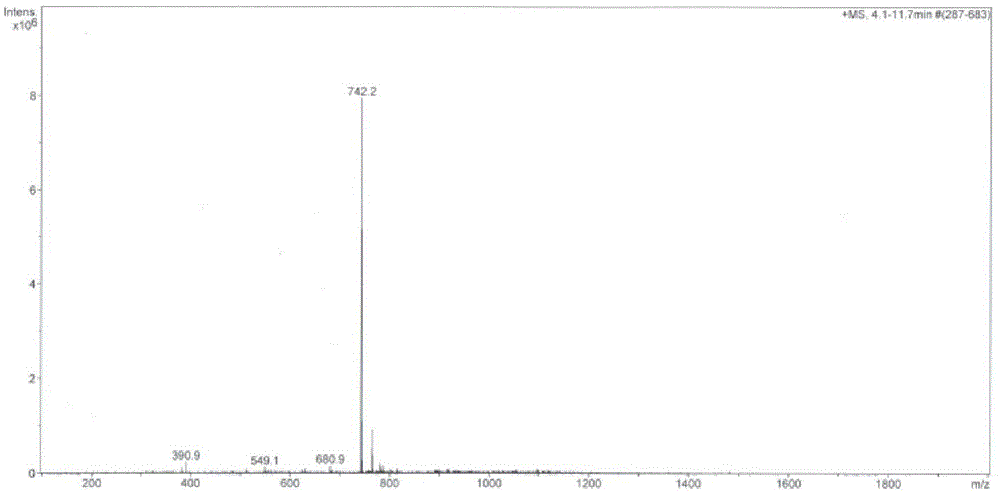

[0064] (5) Reversed-phase silica gel purification, the eluate is then purified by reverse-phase silica gel, HPLC system: LC-8A Shimadzu preparative high-performance liquid chromatograp...

Embodiment 3

[0071] The amino acid sequence of the hypotensive peptide P16 provided in this example is shown in SEQ ID No.1.

[0072] The above-mentioned high-purity hypotensive peptide P16 is prepared by the following method:

[0073] (1) Take casein and dissolve it with water to obtain an aqueous solution of casein, wherein the amount of water is 5 times the total mass of casein, and the dissolution temperature is 50°C;

[0074] (2) Add trypsin to the aqueous solution of casein for enzymolysis, the amount of trypsin added accounts for 0.15% of the total mass of casein, the enzymolysis temperature is 45°C, the enzymolysis time is 1.5h, and the pH value is 8.0. Enzyme inactivation treatment was carried out after the hydrolysis, the temperature during inactivation was 85°C, and the inactivation time was 25min to obtain an enzyme inactivation solution;

[0075] (3) Adjusting the pH value to 4.5 so that the unenzymolyzed macromolecules in the enzyme-inactivating solution are precipitated for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com