Water-in-oil type polyamide emulsifier for drilling fluid and synthetizing method thereof

A water-in-oil type, synthetic method technology, applied in chemical instruments and methods, drilling compositions, preparation of carboxylic acid amides, etc. Small, solve the effect of poor rheological properties and good rheological properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

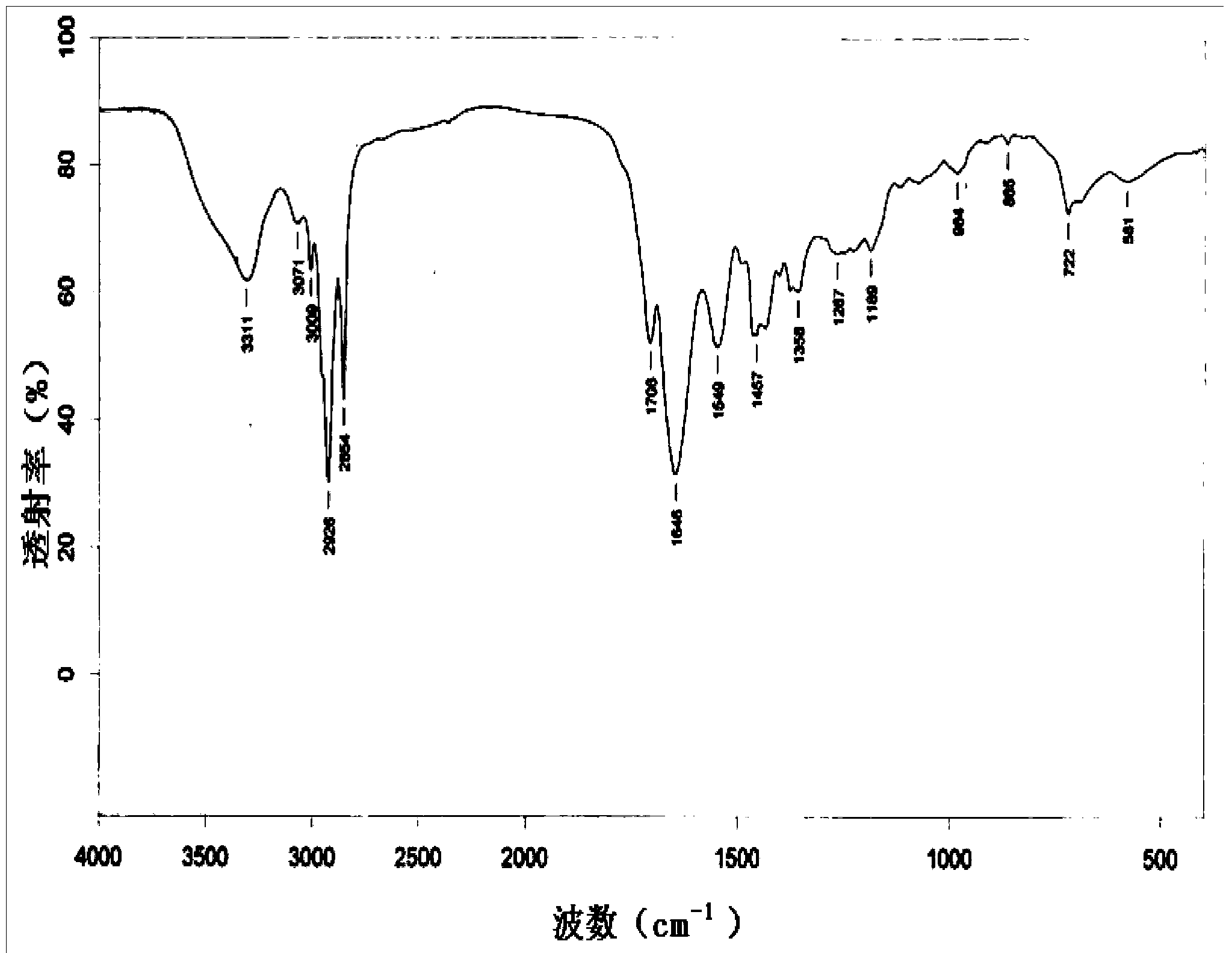

Image

Examples

specific Embodiment approach 1

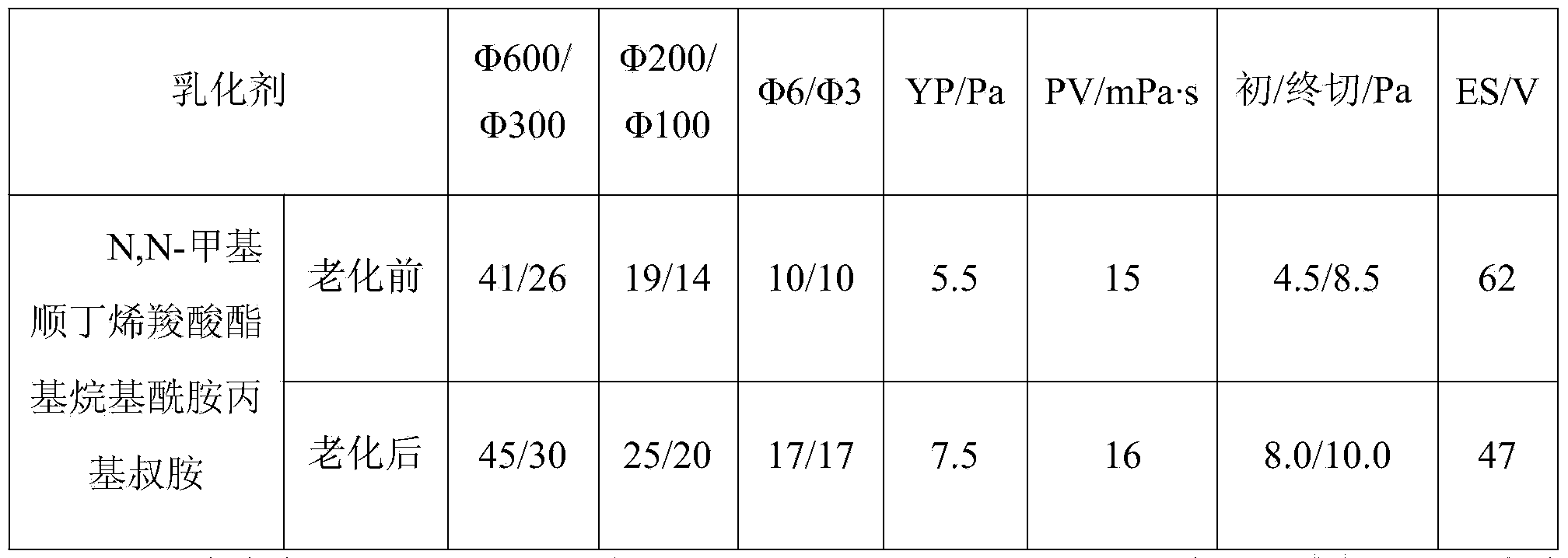

[0018] Specific Embodiment 1: In this embodiment, a water-in-oil polyamide emulsifier for drilling fluid is prepared from N-methyl-1,3-propylenediamine, oleic acid and maleic anhydride as raw materials. The name is N,N-methylmaleic acid ester alkyl amidopropyl tertiary amine, and the general structure is HOOC-CH=CH-CO-N(CH 3 )-(CH 2 ) 3 -NH-CO-R; where R is CH 3 (CH 2 ) 2 -CH=CH-(CH 2 ) 7 -.

specific Embodiment approach 2

[0019] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the synthetic method of the water-in-oil type polyamide emulsifier for the drilling fluid is carried out according to the following steps:

[0020] 1. Add N-methyl-1,3-propanediamine and oleic acid into the three-necked bottle, fix the three-necked bottle in the electric heating mantle, insert the stirring rod into the straight mouth of the three-necked bottle, fix the stirring device, three-necked The other two ports of the bottle are respectively equipped with a thermometer and a water-splitting condensing device, and the temperature is raised from room temperature to 100°C to 110°C under the condition of stirring, and after keeping for 1 hour, the temperature is raised from 100°C to 110°C to 150°C ~170°C, keep warm for 10h~17h to obtain N-methylalkylamidopropyl secondary amine; the molar ratio of N-methyl-1,3-propanediamine to oleic acid is (0.6~1.2):1 ; The structural for...

specific Embodiment approach 3

[0029] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that in step 1, the temperature is raised from 110°C to 160°C. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com