Hypereutectic high-chromium white cast iron and preparation method thereof

A high-chromium white cast iron and hypereutectic technology, applied in the direction of improving process efficiency, etc., can solve the problems of porosity in castings, limited refinement of hypereutectic high-chromium cast iron, low toughness of high-chromium cast iron with nitrogen addition, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

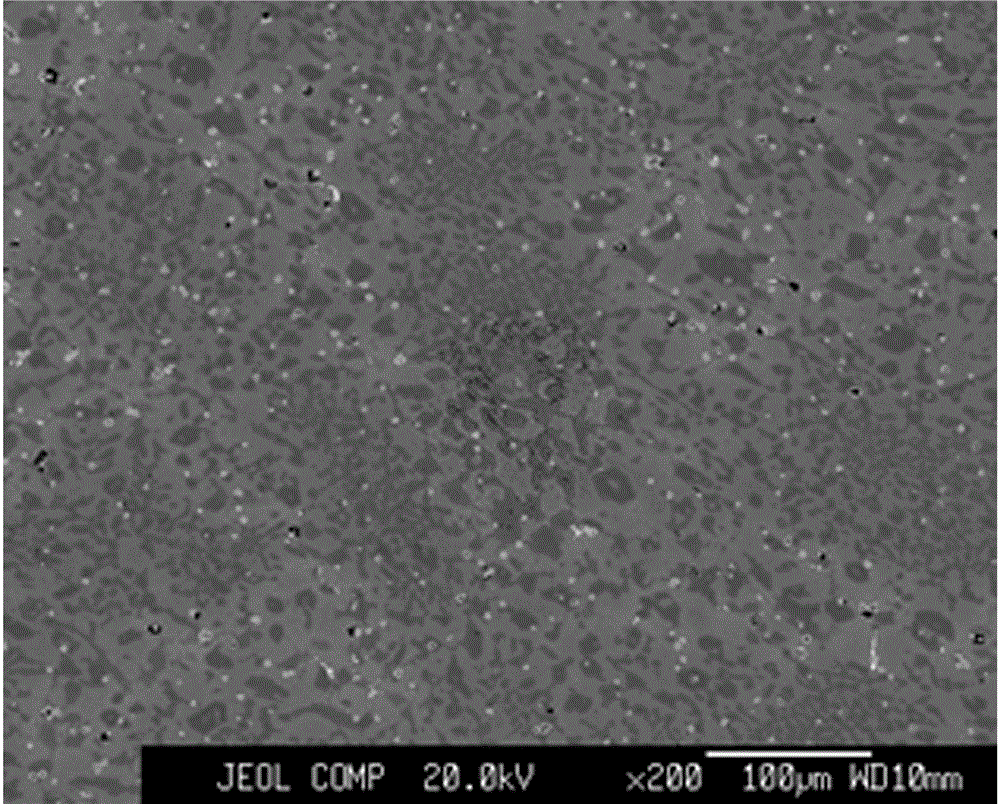

Image

Examples

Embodiment 1

[0034] Hypereutectic high chromium white cast iron composition and mass percentage: C: 3.7%, Cr: 29%, Si: 0.6%, Mn: 0.6%, Ti: 1.9%, W: 3.8%, P, S≤0.04% , Al: 0.025%, Y: 0.2%, and the balance is Fe.

[0035] Put lime in the bottom of the furnace, add steel scrap, high-carbon ferrochrome, and pig iron into the medium-frequency induction furnace with vacuum system in proportion, open the furnace cover to transmit electricity, add slag-forming materials when molten iron is seen in the furnace, and when the furnace charge is completely melted, Scrape slag-making materials to make new slag, add ferrosilicon and ferromanganese into the furnace for pre-deoxidation according to the weight percentage of 1.5%, wait for 8 minutes, take the pre-furnace sample for analysis, and adjust the hypereutectic high-chromium white according to the analysis results of the pre-furnace sample. Cast iron composition, after the composition is qualified, the furnace slag is grilled, and new slag is made a...

Embodiment 2

[0039] Hypereutectic high chromium white cast iron composition and mass percentage: C: 4.0%, Cr: 28%, Si: 0.6%, Mn: 0.6%, Ti: 2.1%, W: 4.2%, P, S≤0.04% , Al: 0.025%, Y: 0.25%, and the balance is Fe.

[0040] Put lime in the bottom of the furnace, add steel scrap, high-carbon ferrochrome, and pig iron into the medium-frequency induction furnace with vacuum system in proportion, open the furnace cover to transmit electricity, add slag-forming materials when molten iron is seen in the furnace, and when the furnace charge is completely melted, Scrape slag-making materials to make new slag, add ferrosilicon and ferromanganese into the furnace for pre-deoxidation according to the weight percentage of 1.5%, wait for 8 minutes, take the pre-furnace sample for analysis, and adjust the hypereutectic high-chromium white according to the analysis results of the pre-furnace sample. After the composition is qualified, the furnace slag is grilled and new slag is made at the same time. The te...

Embodiment 3

[0044] Hypereutectic high chromium white cast iron composition and mass percentage: C: 4.3%, Cr: 27%, Si: 0.6%, Mn: 0.6%, Ti: 2.3%, W: 4.6%, P, S≤0.04% , Al: 0.025%, Y: 0.25%, and the balance is Fe.

[0045] Put lime in the bottom of the furnace, add steel scrap, high-carbon ferrochrome, and pig iron into the intermediate frequency induction furnace with vacuum system in proportion, open the furnace cover to transmit electricity, add slag-forming materials when molten iron is seen in the furnace, and when the furnace charge is completely melted, Scrape slag-making materials to make new slag, add ferrosilicon and ferromanganese into the furnace for pre-deoxidation according to the weight percentage of 1.5%, wait for 8 minutes, take the pre-furnace sample for analysis, and adjust the hypereutectic high-chromium white according to the analysis results of the pre-furnace sample. After the composition is qualified, the furnace slag is grilled and new slag is made at the same time. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com