Heating system for airport bituminous concrete runway

A technology of asphalt concrete and heating system, which is applied in the direction of roads, roads, pavement details, etc., can solve the problems of affecting road surface heating, incomplete deicing and snow removal, and high cost, so as to ensure safe taxiing, high effective utilization of heat, and maintenance low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

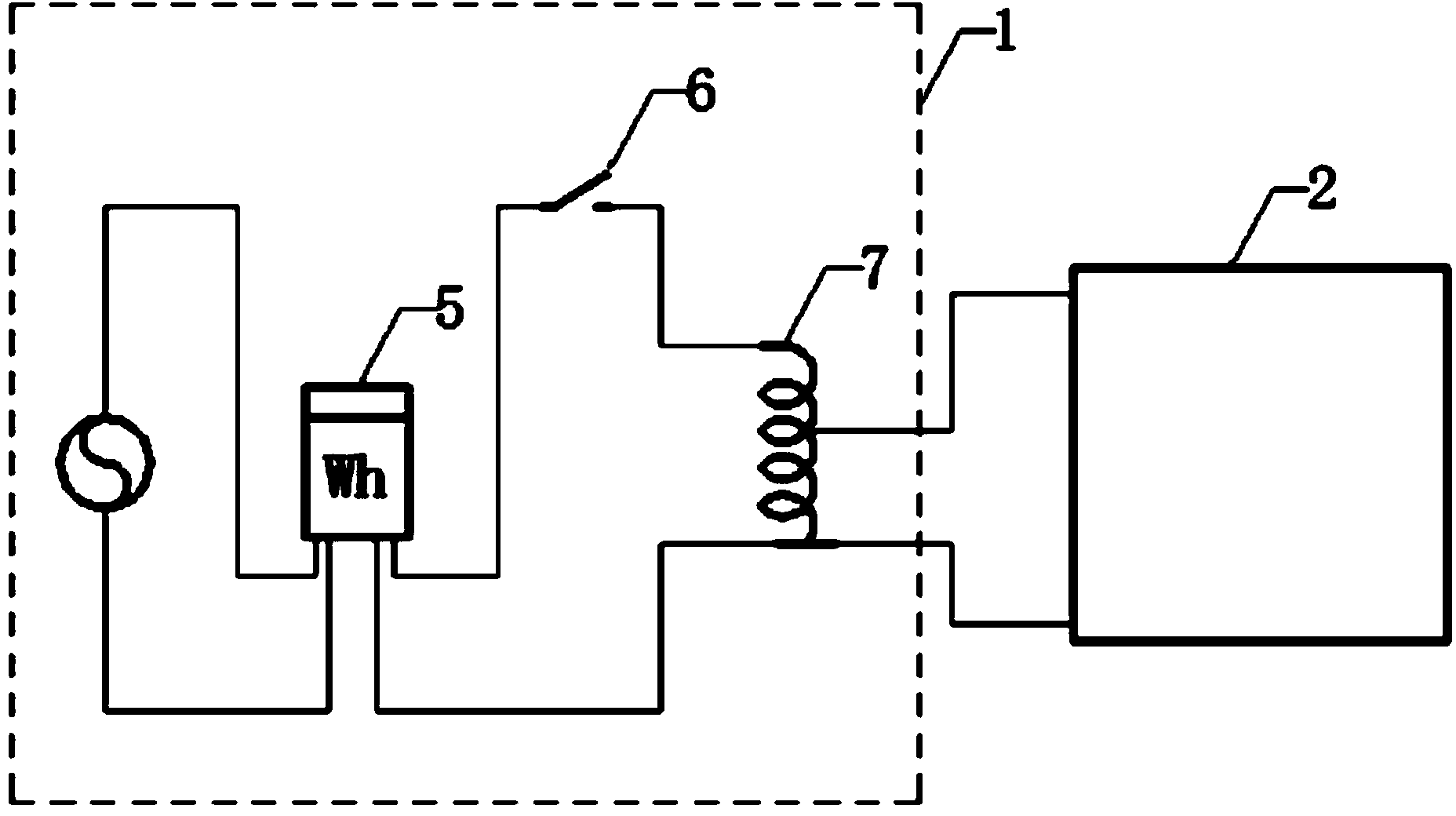

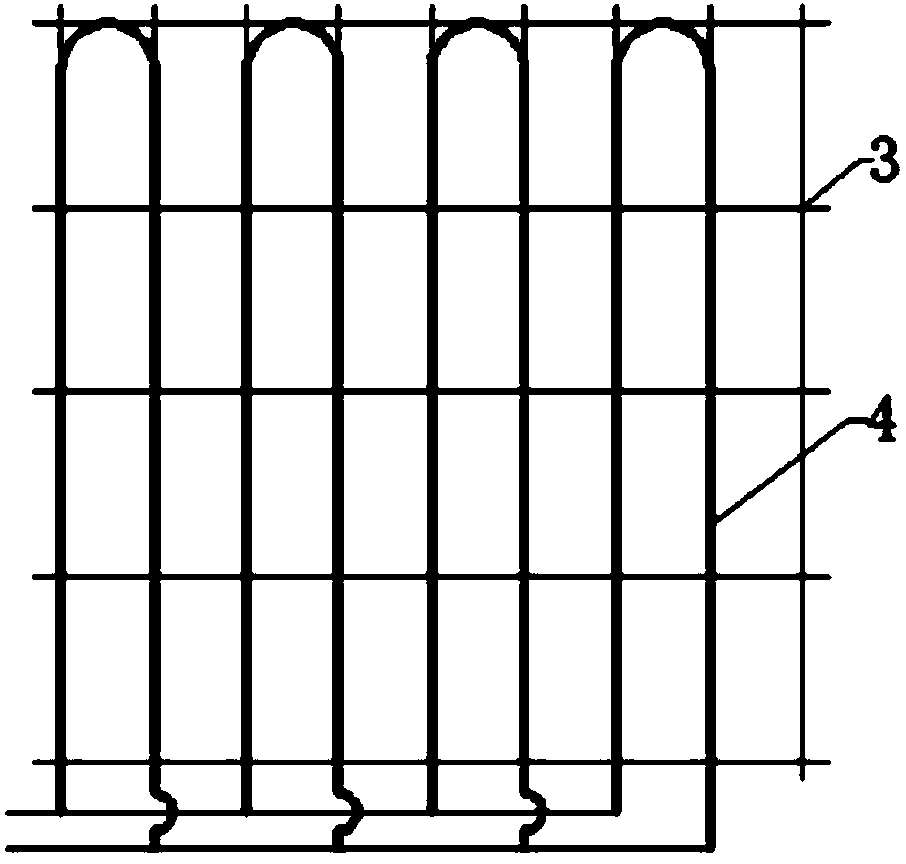

[0015] Such as figure 1 , 2 As shown, the airport asphalt concrete pavement heating system of the present invention includes an electric heating layer 2 located inside the airport asphalt concrete pavement, and a heating circuit 1 connected to the electric heating layer 2; the electric heating layer 2 includes steel wire mesh or geogrid The grid 3 and the carbon fiber heating wire 4 are arranged in a serpentine shape along the steel wire mesh or geogrid 3.

[0016] The spacing of the carbon fiber heating wires 4 is 4 cm to 15 cm.

[0017] The carbon fiber heating wire 4 includes carbon fiber threads, the surface of which is provided with a Teflon layer, the outer surface of the Teflon is covered with a protective film, and the outer surface of the protective film is covered with a stainless steel wire mesh.

[0018] The heating circuit 1 includes an electric energy meter 5, a manual switch 6 and an AC voltage regulator 7; the two input ends of the electric energy meter 5 are connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com