Method for preparing ammonium chloride

A technology of ammonium chloride and magnesium chloride, applied in ammonium halide, magnesium hydroxide and other directions, can solve the problem of complex and high cost of flame-retardant magnesium oxide process, and achieve the effects of easy filtration and washing, high purity, and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

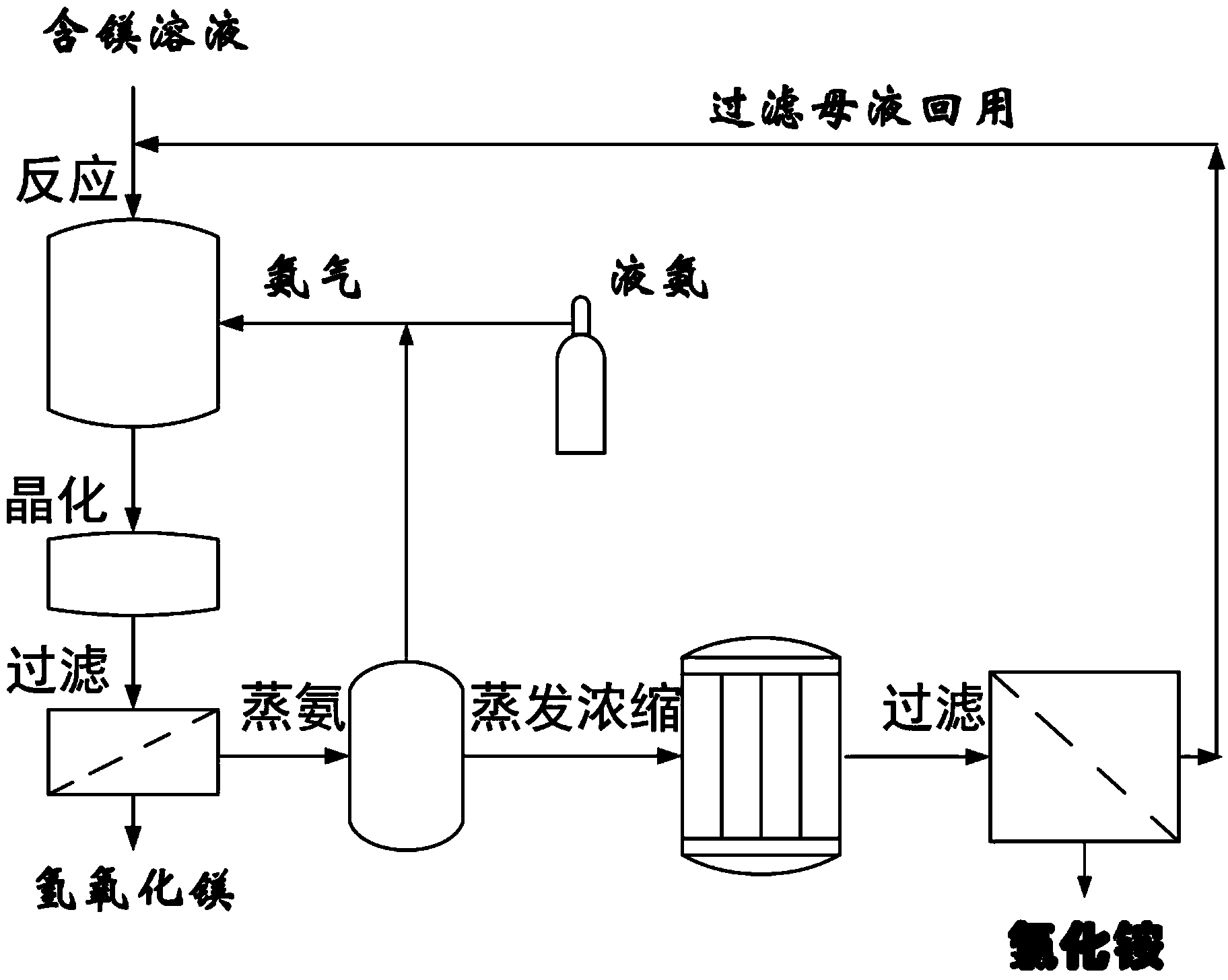

[0026] see figure 1 , according to a certain ratio, mix the old bittern for extracting potassium, evaporate the mother liquor and water, so that the concentration of magnesium chloride reaches 15% (w / w), and add it to a 2L stirring reactor according to the feed rate of 0.8L / h, and the liquid ammonia According to the speed of 1.4mol / h, it is passed from the bottom of the reaction kettle, the stirring intensity is 650rpm, the reaction is carried out at 40°C, and the reaction mother liquor containing magnesium hydroxide precipitate is obtained through overflow.

[0027] The above reaction mother liquor was filtered to obtain magnesium hydroxide solid and primary mother liquor, and the obtained magnesium hydroxide precipitate was washed and dried to obtain a magnesium hydroxide product with a purity of 99.8% and a median particle size D50 of 35.1 μm.

[0028] After the primary mother liquor is distilled under reduced pressure, the secondary mother liquor is obtained, and the obtai...

Embodiment 2

[0031] According to a certain ratio, mix the old bittern for extracting potassium, evaporate the mother liquor and water, make the concentration of magnesium chloride reach 20% (w / w), join in the stirred reaction kettle of 5L according to the feeding speed of 5.0L / h, liquid ammonia according to The speed of 18mol / h is passed from the bottom of the reaction kettle, the stirring intensity is 600rpm, the reaction is carried out at 60°C, and the reaction mother liquor containing magnesium hydroxide precipitate is obtained through overflow.

[0032] The above reaction mother liquor was filtered to obtain magnesium hydroxide solid and primary mother liquor, and the obtained magnesium hydroxide precipitate was washed and dried to obtain a magnesium hydroxide product with a purity of 99.6% and a median particle size D50 of 29.3 μm.

[0033] After the primary mother liquor is distilled under reduced pressure, the secondary mother liquor is obtained, and the obtained ammonia gas is absor...

Embodiment 3

[0036] According to a certain ratio, mix the old bittern for potassium extraction, evaporate the mother liquor and water, so that the concentration of magnesium chloride reaches 25% (w / w), and add it into a 10L stirring reactor according to the feed rate of 15L / h, and the liquid ammonia is 95mol The speed of / h is passed from the bottom of the reactor, the stirring intensity is 244rpm, the reaction is carried out at 90°C, and the reaction mother liquor containing magnesium hydroxide precipitate is obtained through overflow.

[0037] The above reaction mother liquor was filtered to obtain magnesium hydroxide and primary mother liquor, and the obtained magnesium hydroxide precipitate was washed and dried to obtain a magnesium hydroxide product with a purity of 99.2% and a median particle size D50 of 23.5 μm.

[0038] After the primary mother liquor is distilled under reduced pressure, the secondary mother liquor is obtained, and the obtained ammonia gas is absorbed by the potassi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com