A kind of preparation method of liquid piperylene petroleum resin

A technology of petroleum resin and pentadiene, which is applied in the field of liquid piperylene petroleum resin, can solve the problems of low resin softening point, achieve short reaction time, save electric energy, and improve economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

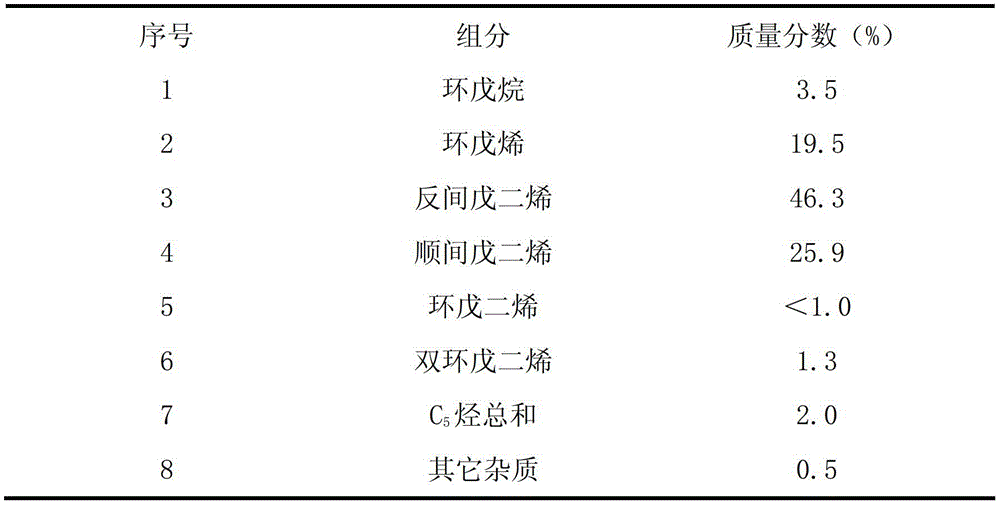

Method used

Image

Examples

Embodiment 1

[0027] 100 g of solvent toluene, 0.5 g of aluminum trichloride catalyst, 98 g of piperylene concentrate (containing 0.1 g of trace water) and 2.0 g of propenyltriethoxysilane were added dropwise in the reactor. The dropping rate is controlled, the dropping temperature is <20°C, the reaction temperature is 40°C, and the reaction time is 4h. Carry out one alkali wash, two water washes, and separate layers. After removing the catalyst from the upper layer, vacuumize at 200°C to obtain piperylene petroleum resin with a product yield of 85%, color number (Fe-Co)﹦3, softening point less than 20°C, and liquid state at room temperature.

Embodiment 2

[0029] Add 100 g of solvent toluene, 0.5 g of aluminum trichloride catalyst, 97 g of piperylene concentrate (containing a small amount of water 0.15 g), and 3.0 g of vinyltriacetoxysilane into the reaction kettle. The dropping rate is controlled, the dropping temperature is <20°C, the reaction temperature is 40°C, and the reaction time is 4h. Wash with alkali once, wash with water twice, and separate layers; the upper layer is vacuumed to remove the toluene solvent, and the piperylene petroleum resin is obtained. The product yield reaches 82%, the color number (Fe-Co) <3, and the softening point is less than 20°C , liquid at room temperature.

Embodiment 3

[0031] 100 g of solvent toluene, 0.5 g of aluminum trichloride catalyst, 98 g of piperylene concentrate (containing 0.2 g of trace water) and 2.0 g of vinyltriethoxysilane were added dropwise into the reaction kettle. Control the dropping speed, dropping temperature <20°C. The reaction temperature is 40°C, and the reaction time is 4h. Wash with alkali once, wash with water twice, and separate layers; the upper layer is vacuumed to remove the toluene solvent, and the piperylene petroleum resin is obtained. The product yield reaches 84%, the color number (Fe-Co) <3, and the softening point is less than 20°C , liquid at room temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com