Preparation method of straw-based super absorbent resin with nitrogen phosphorus fertilizer slow-release function

A technology of slow-release nitrogen-phosphorus fertilizer and superabsorbent resin, which is applied in the chemical and environmental fields, can solve the problems of low strength, poor salt tolerance and poor environmental friendliness, and achieve the effects of low cost, simple and convenient production process, and high water retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

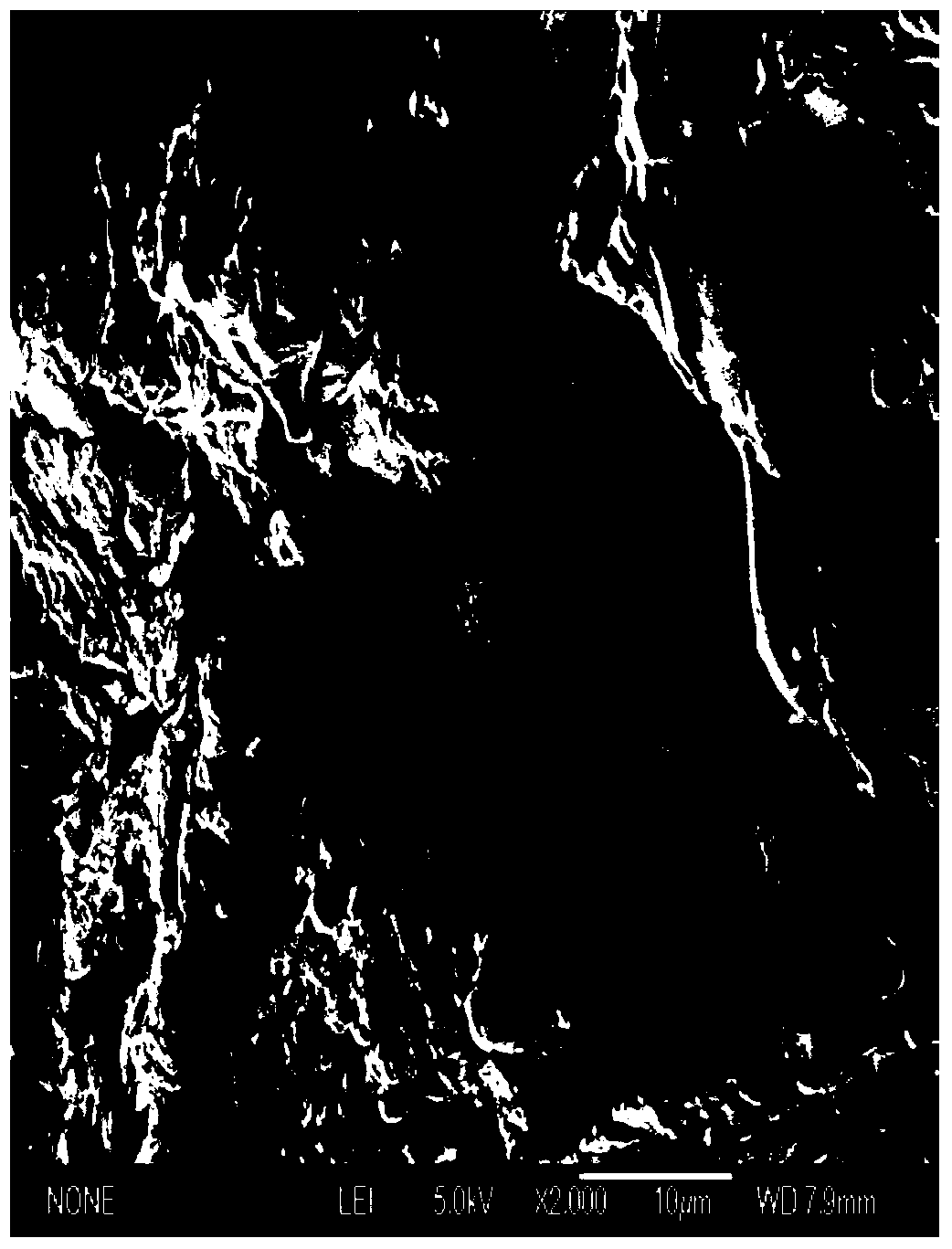

Image

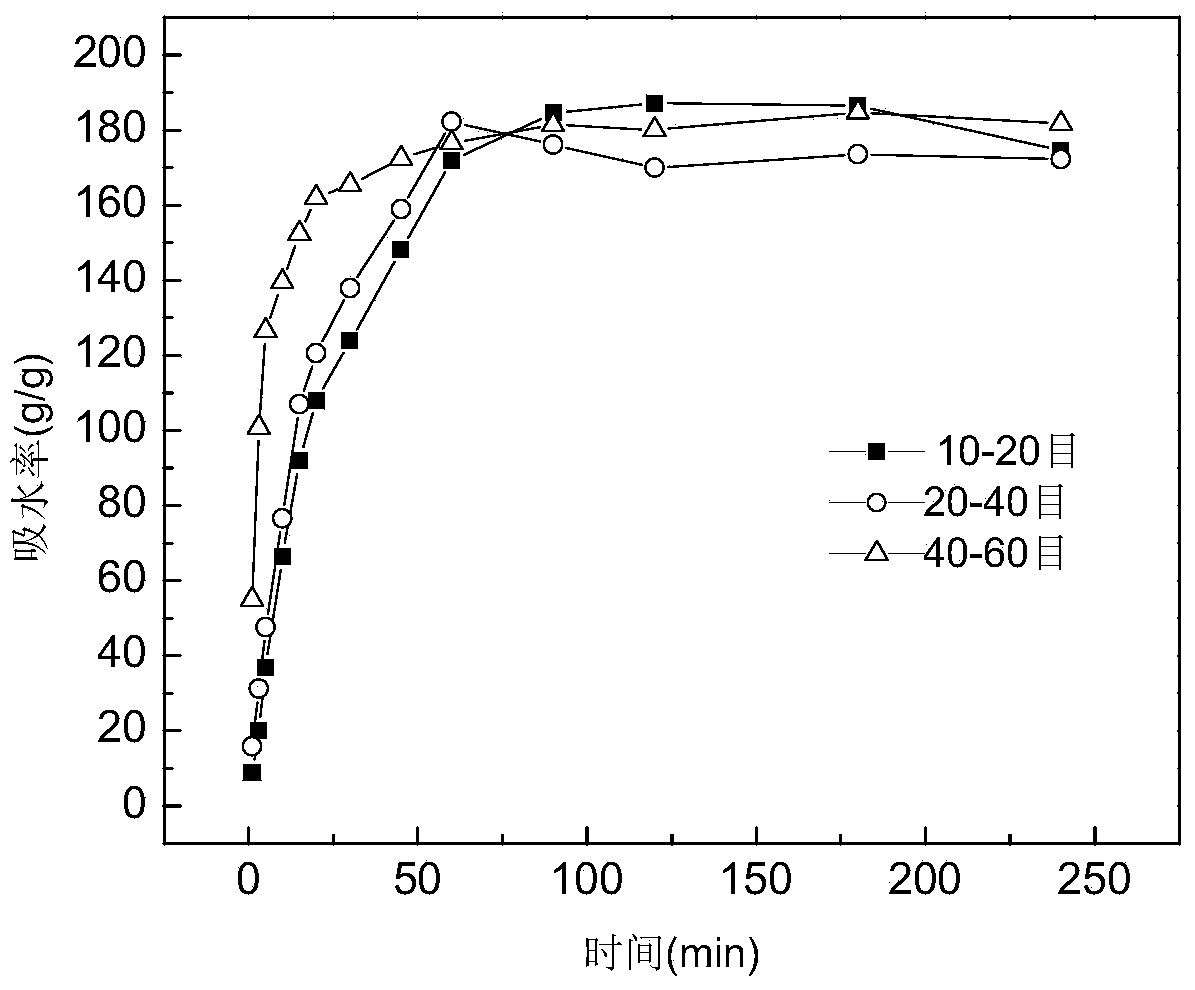

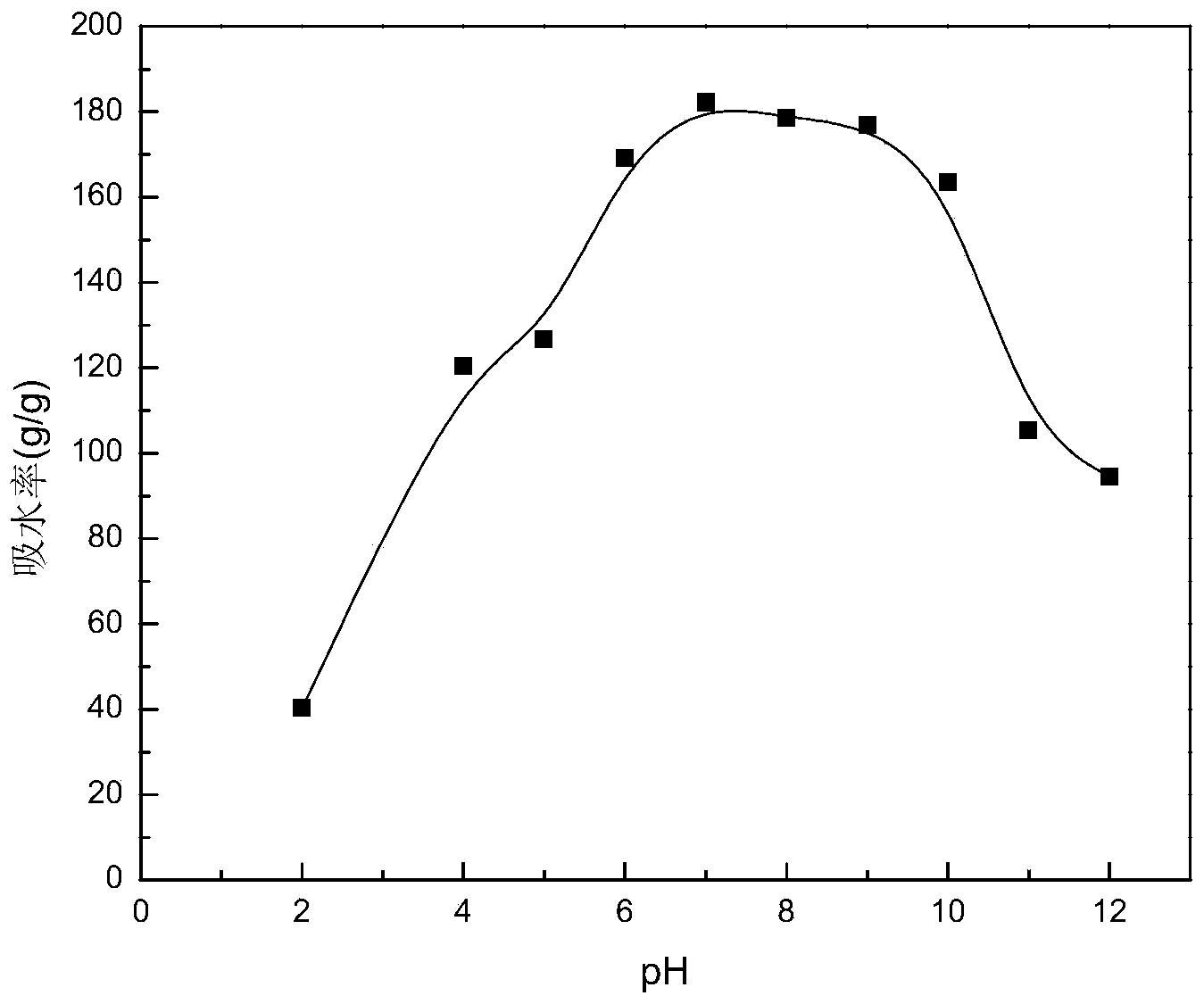

Examples

Embodiment 1

[0041]A method for preparing a straw-based superabsorbent resin with the function of slow-release nitrogen and phosphorus fertilizers, the steps are as follows:

[0042] (1) After washing the wheat straw, dry it at 70±5°C, then crush it and pass it through a 100-mesh sieve, and collect the sieved straw powder for subsequent use;

[0043] (2) Soak the straw powder collected in step (1) in ammonia water with a concentration of 10wt% for 48±5 hours, wherein the mass ratio of straw powder and ammonia water is 1:12, suction filter, and wash the solid with water until the water is cleaned. Collect straw powder when it is colorless and dry it at 70±5°C;

[0044] (3) Take the straw powder dried in step (2), treat it in 1mol / L nitric acid solution at 100±2°C for 45±5min, filter it with suction, wash the solid with water until the washed water is colorless Collect the straw powder and dry it at 70±5°C; grind the dried straw powder with a mortar, pass through a 100-mesh sieve, and colle...

Embodiment 2

[0050] A method for preparing a straw-based superabsorbent resin with the function of slow-release nitrogen and phosphorus fertilizers. The preparation steps are the same as in Example 1, except that the amount of crosslinking agent is changed: adding 3ml of N,N'-sub- Methyl bisacrylamide solution, all the other operations, consumption are identical with embodiment 1.

[0051] It is determined that the maximum water absorption rate of the obtained superabsorbent resin can reach 175.05g / g, and the maximum salt water absorption rate can reach 22.15g / g.

Embodiment 3

[0053] A method for preparing a straw-based superabsorbent resin with the function of slow-release nitrogen and phosphorus fertilizers, the steps are as follows:

[0054] (1) drying the wheat straw after cleaning, pulverizing, passing through a 100-mesh sieve, and collecting the sieved straw powder for subsequent use;

[0055] (2) Soak the stalk powder obtained in step (1) in 10wt% ammonia water for 40 hours, suction filter, wash the solid with water, and dry at 65°C. The stalk powder obtained in the step (1) and ammonia water The mass ratio is 1:10;

[0056] (3) Take the straw powder obtained after drying in step (2), treat it in 2mol / L nitric acid solution at 95°C for 40min, filter with suction, wash the solid with water, dry at 65°C, grind, and pass through 100 mesh sieve, spare;

[0057] (4) Put the straw powder prepared in step (3) into a three-necked flask, add an initiator, and initiate for 15 minutes; add urea and acrylic acid with a neutralization degree of 55%; add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com