Method for preparing micro intercommunicated hole structure transmission electron microscope sample

A technology of transmission electron microscope samples and interconnecting through holes, which is applied in the preparation of test samples, etc., can solve the problems of complicated operation process, easy introduction of pollution, expensive equipment, etc., and achieves simple process flow, no ion pollution, and convenient operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

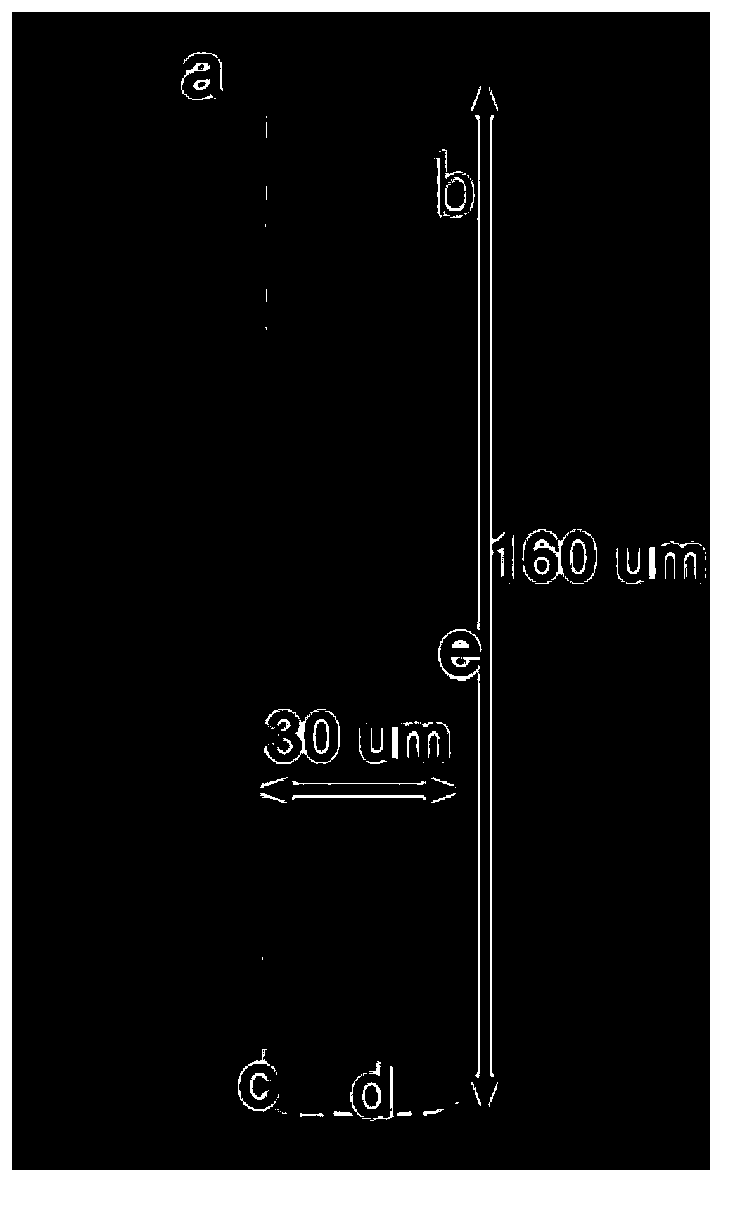

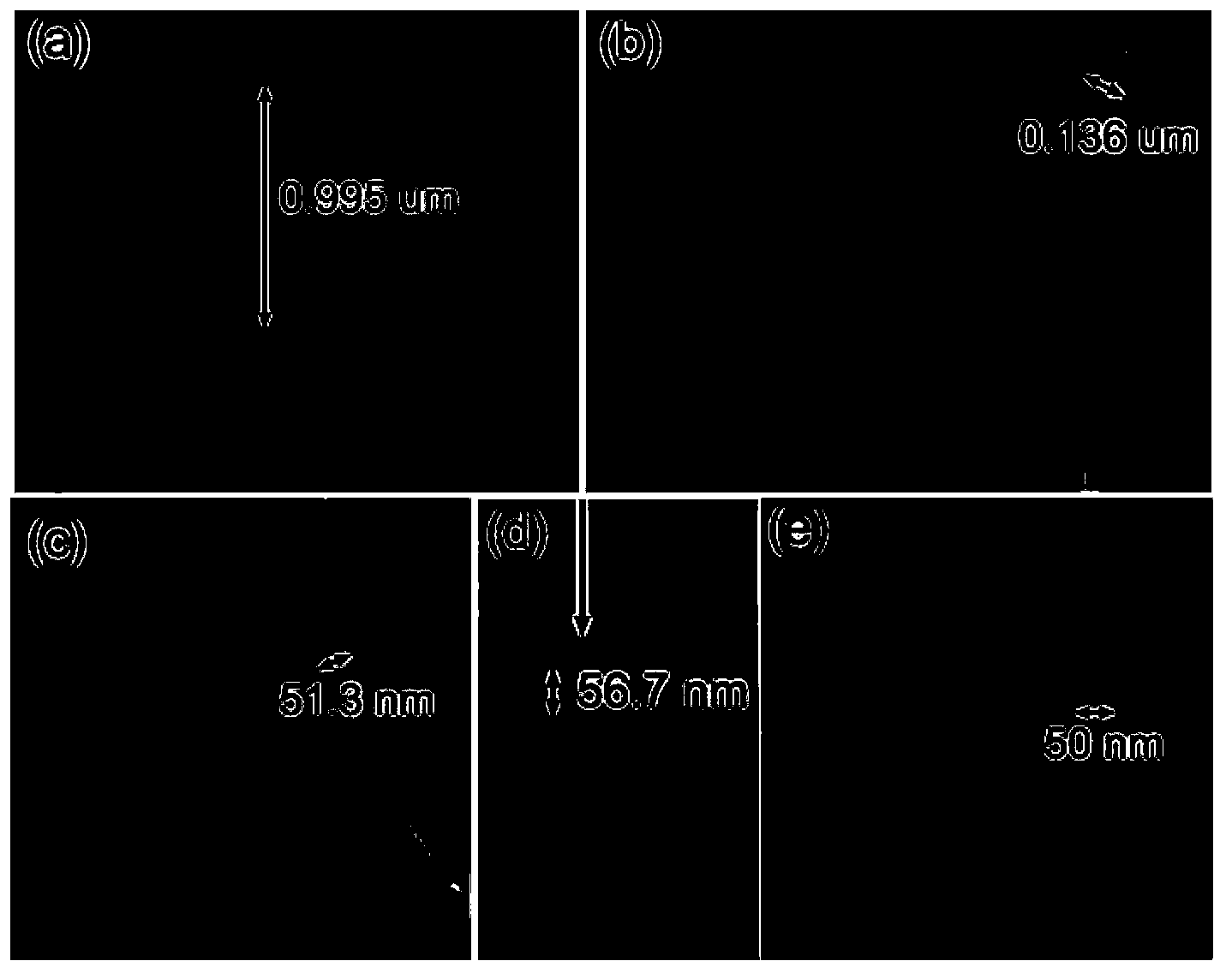

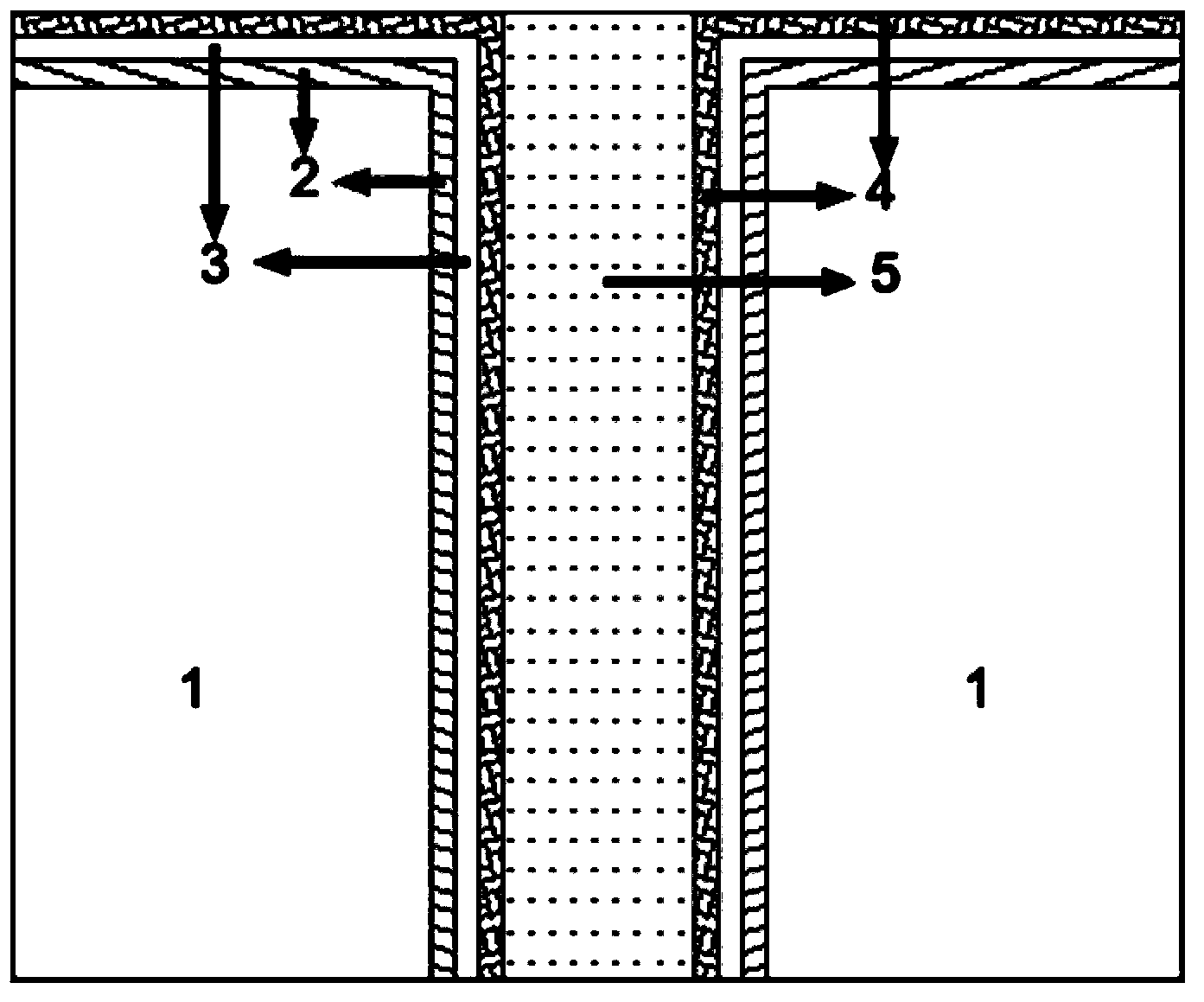

[0041] (1) The TSV through hole is a blind hole, and the size of the through hole is: 30 μm in diameter and 160 μm in depth.

[0042] (2) The TEM sample preparation of the surface position of the TSV, the upper surface of two samples of the same size are directly bonded to make a cross-sectional sample; among them, the adhesive is 502 adhesive with α-ethyl cyanoacrylate as the main component, and with The volume ratio of acetone is 1:20; use 2000# sandpaper to grind the sample to the thickness required for thinning. In this example, the thickness is 30 μm, and then use Gatan691.HA200 ion thinner for thinning.

[0043] (3) Technical parameters of Gatan691.HA200 ion thinner during thinning: the thinning voltage is 5KV, the thinning current is 5-30μA, the thinning angle is 5°, and the thinning time varies with the thickness of the sample.

[0044] (4) Select the JEM2100 transmission electron microscope as the observation equipment, put the material into the transmission electron ...

Embodiment 2

[0046] (1) The TSV through hole is a blind hole, and the size of the through hole is: 30 μm in diameter and 160 μm in depth.

[0047] (2) Preparation of the transmission electron microscope sample at the upper part of the TSV (the distance from the upper surface of the through hole is 5 μm), and the large through-hole structure substrate is cut into 4×4mm with a glass knife 2 Put the small pieces into the adhesive diluted with acetone and soak for 5 minutes.

[0048] (3) Vibrate the sample placed in the adhesive diluted with acetone with an ultrasonic cleaner; wherein, the adhesive is 502 adhesive with α-ethyl cyanoacrylate as the main component, and the volume ratio of the adhesive to acetone is 10 ﹪; take out the ultrasonically sounded sample and place it in the air, after the acetone is completely evaporated, the liquid adhesive solidifies in the TSV.

[0049] (4) The surface of the sample is stuck on a glass sheet of a certain thickness, and the sample is ground to the th...

Embodiment 3

[0052] (1) The TSV through hole is a blind hole, and the size of the through hole is: 50 μm in diameter and 100 μm in depth.

[0053] (2) The preparation of the transmission electron microscope sample at the middle position of the TSV (the distance from the upper surface of the through hole is 50 μm) will be cut into 5×5mm with a glass knife 2 Small pieces of samples with TSVs were placed in an adhesive diluted with acetone and soaked for 10 minutes.

[0054] (3) Use an ultrasonic cleaner to oscillate the sample placed in the acetone-diluted adhesive (oscillate for 5 minutes); wherein, the adhesive is 502 adhesive mainly composed of α-ethyl cyanoacrylate, and the volume ratio of adhesive to acetone is 1: 5. Take out the ultrasonically sounded sample and place it in the air, so that the liquid adhesive solidifies in the TSV after the acetone is completely evaporated.

[0055] (4) Stick the lower surface of the sample on a glass sheet of a certain thickness, grind the sample to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com