Method for preparing LED by means of quantum dot composite fluorescent particles

A composite fluorescent and quantum dot technology, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of phosphor powder production cost and high energy consumption, narrow color gamut of LED technology, low color rendering index, etc., and achieve fluorescent thermal stability Good performance, wide excitation wavelength range, and high luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Using ZnTe quantum dots and Sr 0.5 Ca 0.5 MoO 4 Preparation of Inorganic Fluorescent Particles to Obtain Composite Fluorescent Particles Sr 0.5 Ca 0.5 MoO 4 / ZnTe is used as a yellow phosphor, mixed in silica gel at a ratio of 5:100, and directly coated on the blue light chip. Filling glue, after the filling glue is cured at 100°C for 100 minutes, the LED device can be obtained, such as figure 1 As shown, this LED device emits yellow light.

Embodiment 2

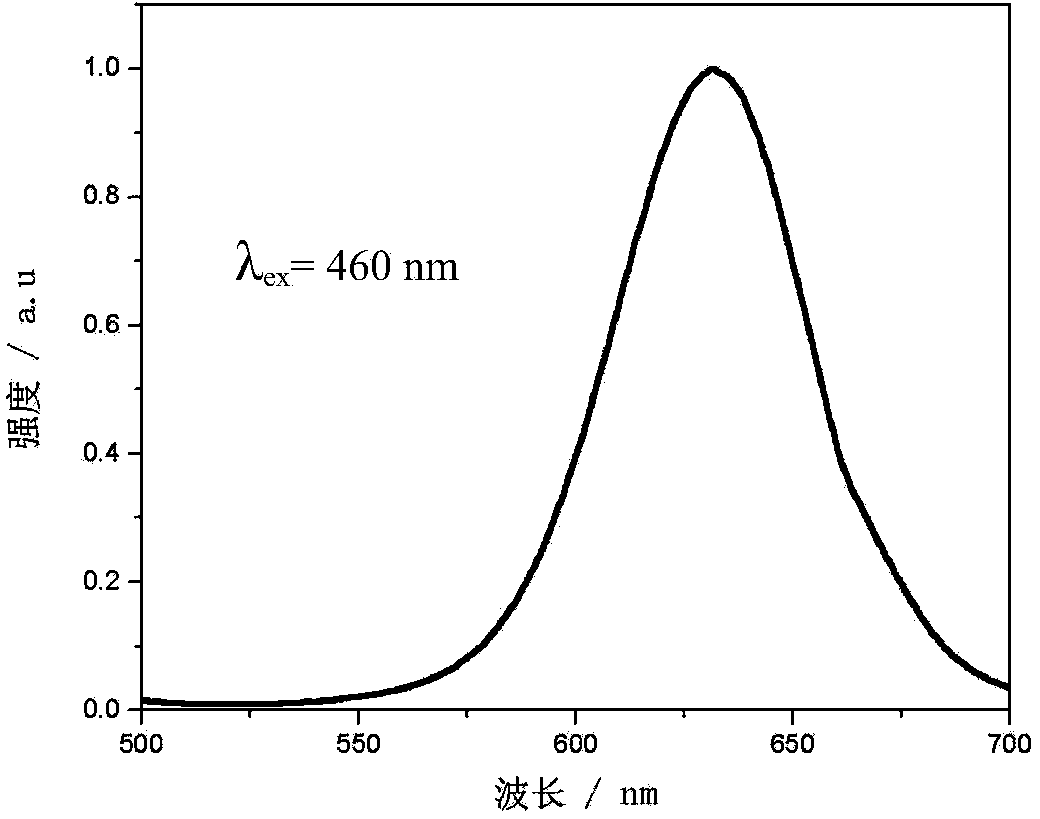

[0023] Using red fluorescent CdTe quantum dots and NaLa(MoO 4 ) 2 Preparation of inorganic fluorescent particles to obtain composite fluorescent particles NaLa(MoO 4 ) 2 / CdTe is used as red phosphor, mixed in silica gel at a ratio of 10:100, and coated on the blue light chip. After the silica gel is cured in an oven at 105°C for 105 minutes, the light-taking lens is covered on the blue light chip and filled. Glue, the filling glue is cured at 105°C for 105 minutes to obtain a red LED. Such as figure 2 As shown, it can be seen that the composite fluorescent particle NaLa(MoO 4 ) 2 / CdTe as a red phosphor has higher fluorescence emission intensity and better fluorescence performance.

Embodiment 3

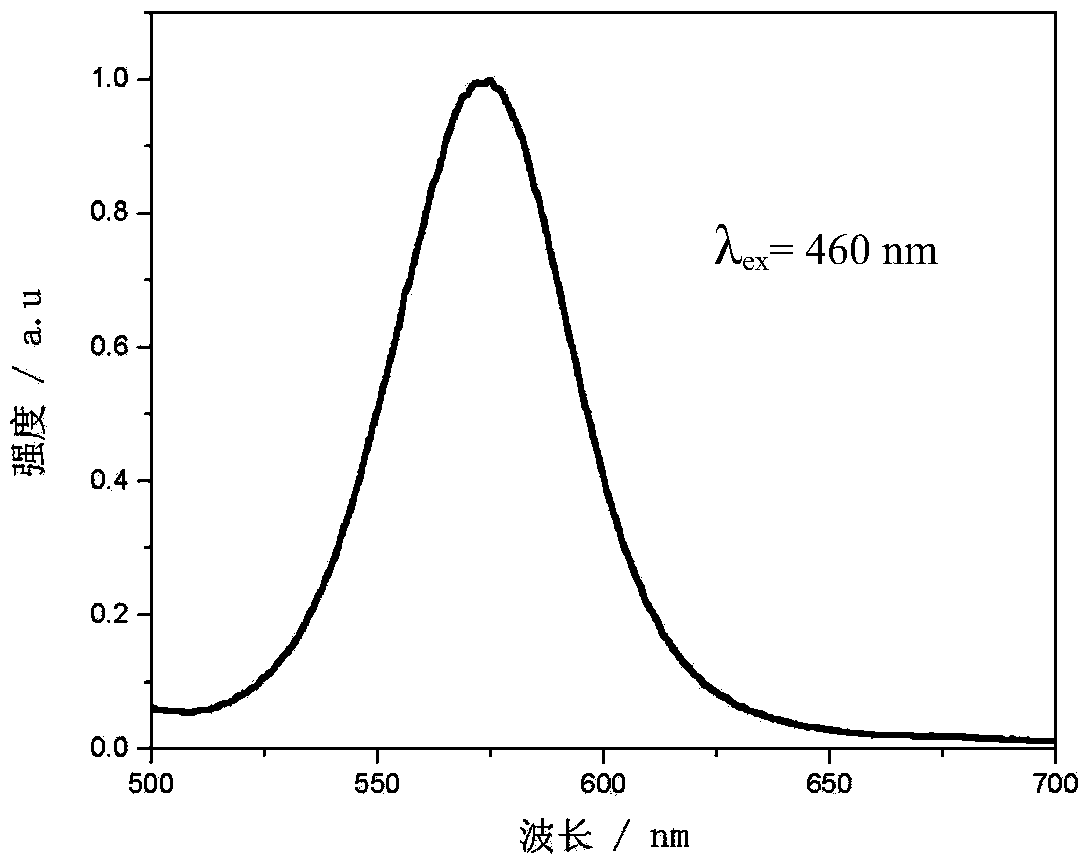

[0025] CdSe Quantum Dots and BaMoO Using Yellow Fluorescent Emission 4 Preparation of Inorganic Fluorescent Particles to Obtain Composite Fluorescent Particle BaMoO 4 / CdSe is used as a yellow phosphor, mixed in silica gel at a ratio of 20:100, and coated on the purple light chip. Filling glue, the filling glue is cured at 110°C for 110 minutes to obtain a yellow LED. Such as image 3 As shown, it can be seen that the composite fluorescent particles BaMoO 4 / CdSe as a yellow phosphor has higher fluorescence emission intensity and better fluorescence performance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com