Preparation method of middle flavor snus

A medium-flavor and snus technology, applied in the field of tobacco, can solve the problems of health threats, short shelf life, high moisture content, etc., and achieve rich taste, satisfy the preference of fragrance, and be easy to accept

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

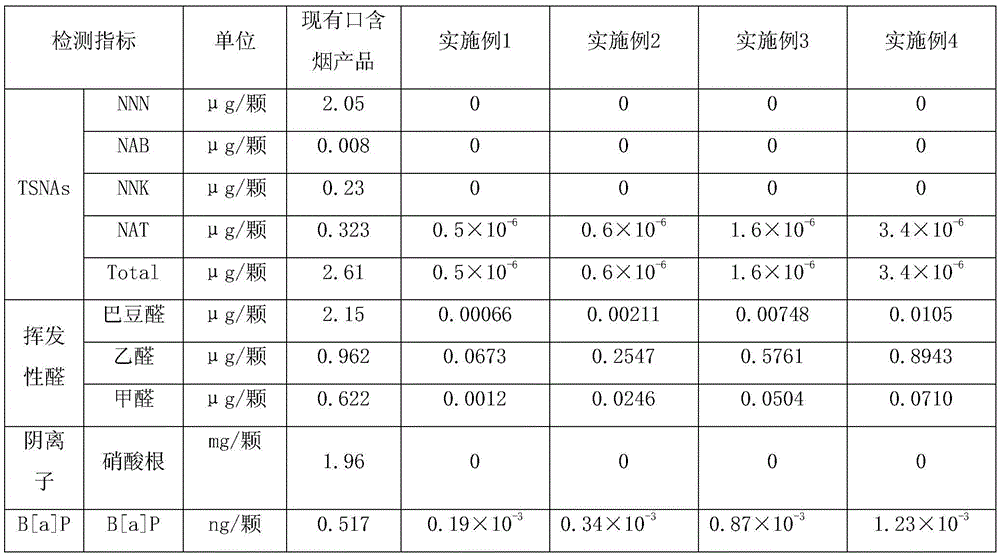

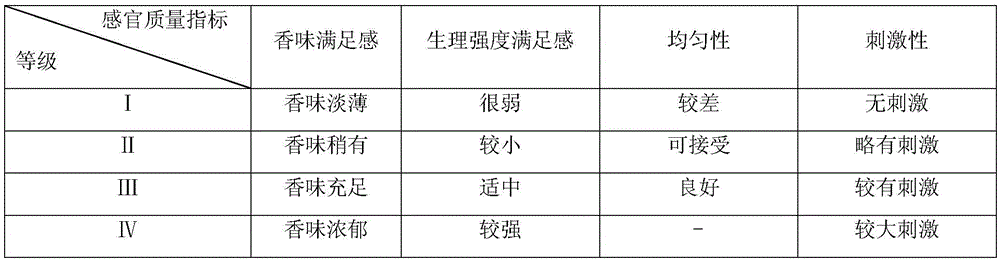

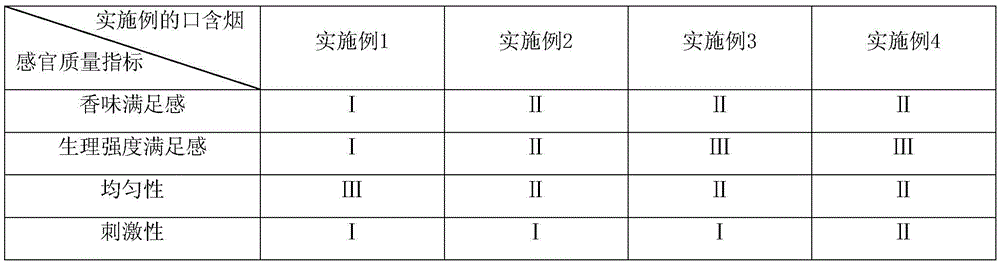

Examples

Embodiment 1

[0019] A method for preparing middle-flavor snus, which comprises the following steps:

[0020] Step 1. Select middle-flavor flue-cured tobacco leaves and place them in an oven at a temperature of 30-60°C for 2-12 hours, then crush and sieve the dried tobacco leaves to obtain 30-80 mesh tobacco powder; weigh Add 48-52 parts of tobacco powder in grams to 590-610 parts in milliliters of deionized water, soak for 0.5-3 hours, ultrasonically extract for 20-90 minutes, and then filter to obtain the water extract. The water extract A water-oil azeotropic tobacco extract containing aroma components and nicotine is obtained by steam distillation. In the steam distillation method, heat and reflux is used for 70 to 300 minutes, and then the tobacco extract is placed at a temperature of -28 to -32 ° C. Vacuum freeze drying for 18-108 hours to obtain concentrated tobacco extract.

[0021] Step 2. Mix 7-9 parts of agar in grams and 210-230 parts of gelatin in grams evenly, and add 38-100 ...

Embodiment 2

[0024] A method for preparing middle-flavor snus, comprising:

[0025] 1) Preparation of tobacco extract: select typical middle-flavor flue-cured tobacco leaves whose place of production is Xianfeng, Hubei, and whose part grade is B2F, dry and pulverize them, pass through a 40-mesh sieve to obtain tobacco powder, weigh 50 parts of tobacco powder in grams and add in milliliters A total of 600 parts of deionized water were mixed, soaked at room temperature for 0.6 hours, ultrasonically extracted for 25 minutes, and the filtered water extract was obtained by steam distillation to obtain a water-oil azeotropic extract containing aroma components and nicotine, which was analyzed by continuous flow Method (YC / T162-2002) detects that the total nicotine content in the extract is 1.94mg / ml. In order to further increase its concentration and make it meet the requirements of the candy preparation process, the aqueous solution of the extract is vacuum-treated at -30°C Freeze-dry for 18 ho...

Embodiment 3

[0032] A method for preparing middle-flavor snus, comprising:

[0033] 1) Preparation of tobacco extract: Select the typical middle-flavor flue-cured tobacco leaves whose place of production is Xianfeng, Hubei, and the part grade is B2F, dry and pulverize them, pass through a 35-mesh sieve to obtain tobacco powder, weigh 50 parts of tobacco powder in grams and add in milliliters A total of 600 parts of deionized water were mixed, soaked at room temperature for 2 hours, ultrasonically extracted for 30 minutes, and the filtered water extract was obtained by steam distillation to obtain a water-oil azeotropic extract containing aroma components and nicotine. In order to further increase its concentration To make it meet the requirements of the candy preparation process, the aqueous extract solution was vacuum freeze-dried at -31°C for 36 hours to obtain a concentrated product, and the concentrated tobacco extract was detected by continuous flow analysis (YC / T162-2002) The total n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com