Mesoporous hollow spherical titanium dioxide preparation method

A technology of hollow spherical titanium dioxide, applied in the field of preparation of mesoporous hollow spherical titanium dioxide, to achieve the effect of stable product shape, easy control of process conditions, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] (1) Accurately weigh 5g of commercially available TiOSO with an electronic balance 4 .xH 2 SO 4 .xH 2 O white powder, placed in a 500mL transparent beaker filled with 200mL deionized water, stirred with a glass rod to make it evenly dispersed in water, and then left to stand for more than 12h to completely dissolve to form a colorless transparent solution;

[0043] (2) TiOSO that will dissolve completely 4 Put the solution into a magnetic stirrer, put a stirring bar, turn on the power, and stir at a medium speed; at the same time, fix a 100mL constant pressure dropping funnel to the iron stand, and pour a certain volume of 3mol / L ammonia water; then Slowly open the glass cock, and drop the excess ammonia into the TiOSO 4 In the solution, use pH test paper to roughly measure the pH during the whole process until the pH of the white precipitate is 9-10;

[0044] (3) Transfer the white precipitate to a cleaned G4 sand core funnel, filter and wash it several times with...

Embodiment 2

[0049] (1) Adopt the equipment and operating steps of steps (1)~(4) and (6) in Example 1, prepare TiOSO by the same method 4 Sol, after aging for more than 6 hours, and dilute according to the volume ratio of sol and deionized water 1:1;

[0050] (2) Spray-dry the diluted sol, keep the compressed air for spray-drying at 0.30MPa, the inlet temperature at 120°C, and the feed flow rate at 400mL / h to obtain light yellow precursor powder;

[0051] (3) Put the obtained pale yellow precursor powder in a crucible, set the temperature program (5°C / min, 700°C for 2h), and calcinate at high temperature in a muffle furnace to obtain mesoporous hollow spherical titanium dioxide powder.

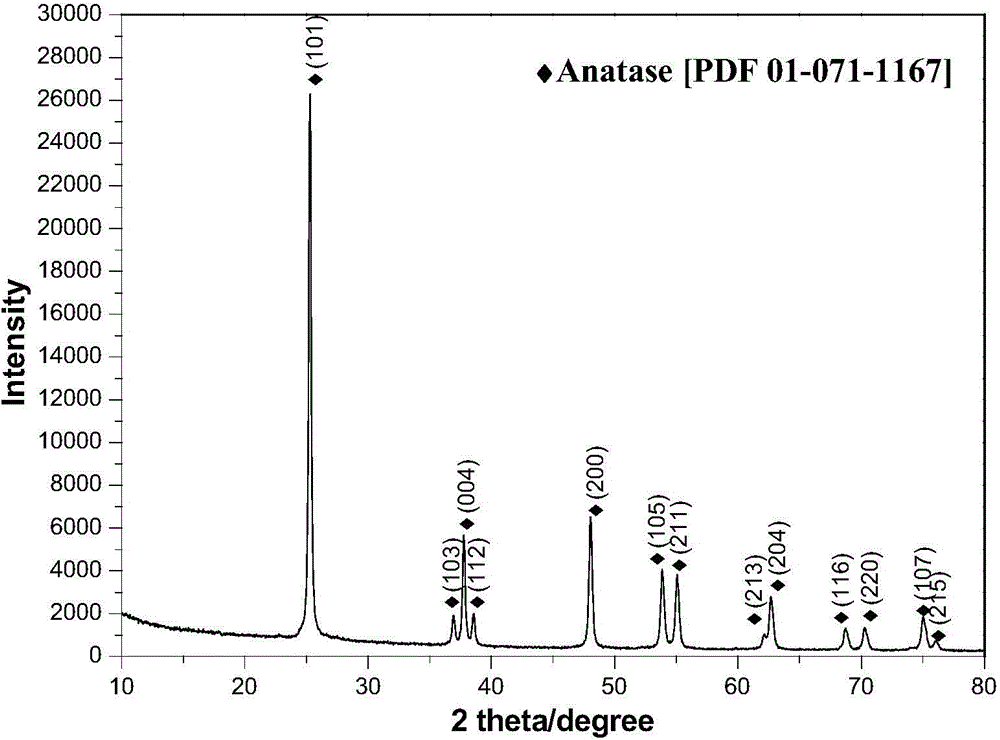

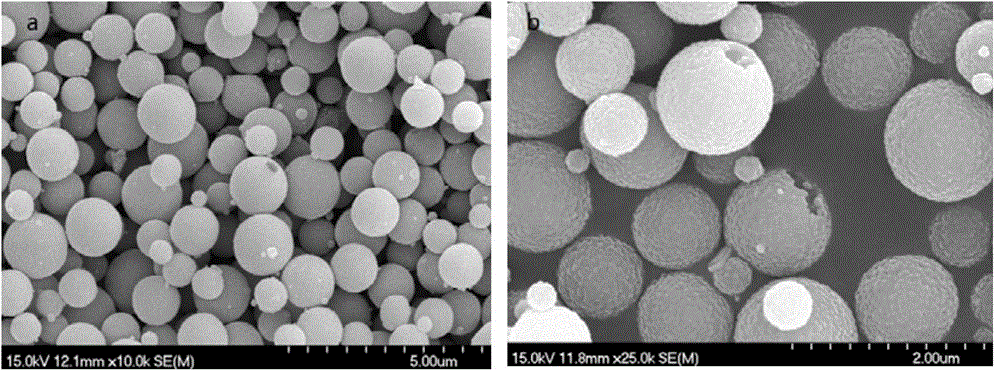

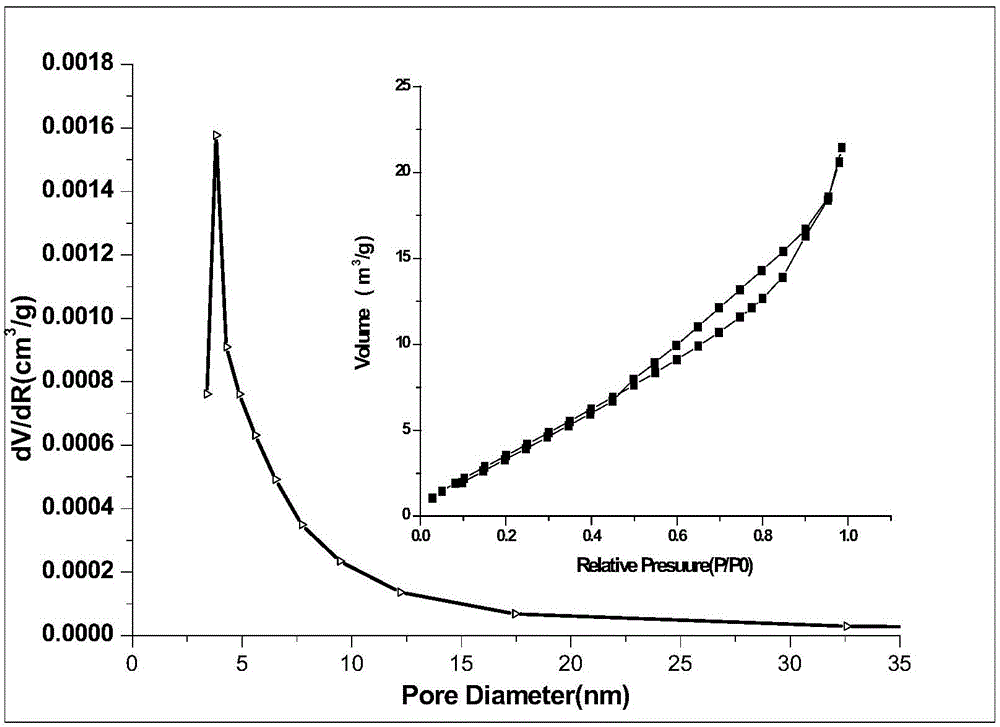

[0052] (4) Characterized by the crystal phase composition of the X'Pert PRO X-ray diffractometer (XRD) sample produced by Holland PANalytical Company, the XRD results are as follows Figure 4 Shown; Hitachi S-4700II type field emission scanning electron microscope is used to characterize the morphology of...

Embodiment 3

[0054] (1) Adopt the equipment and operating steps of steps (1)~(4) and (6) in Example 1, prepare TiOSO by the same method 4 Sol, after aging for more than 24 hours, and dilute according to the volume ratio of sol and deionized water 1:1;

[0055] (2) Spray-dry the diluted sol, keep the compressed air for spray-drying at 0.30MPa, the inlet temperature at 180°C, and the feed flow rate at 900mL / h to obtain light yellow precursor powder;

[0056] (3) Put the obtained pale yellow precursor powder in a crucible, set the temperature program (5°C / min, 700°C for 2h), and calcinate at high temperature in a muffle furnace to obtain mesoporous hollow spherical titanium dioxide powder.

[0057] (4) Characterized by the crystal phase composition of the X'Pert PRO X-ray diffractometer (XRD) sample produced by Holland PANalytical Company, the XRD results are as follows Figure 6 Shown; Hitachi S-4700II type field emission scanning electron microscope is used to characterize the morphology o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com