Preparation method of crystal whisker/fiber synergic reinforced ceramic-base composite material

A composite material and ceramic-based technology, which is applied in the field of preparation of ceramic-based composite materials, can solve problems such as poor bending strength and achieve the effect of improving strength and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

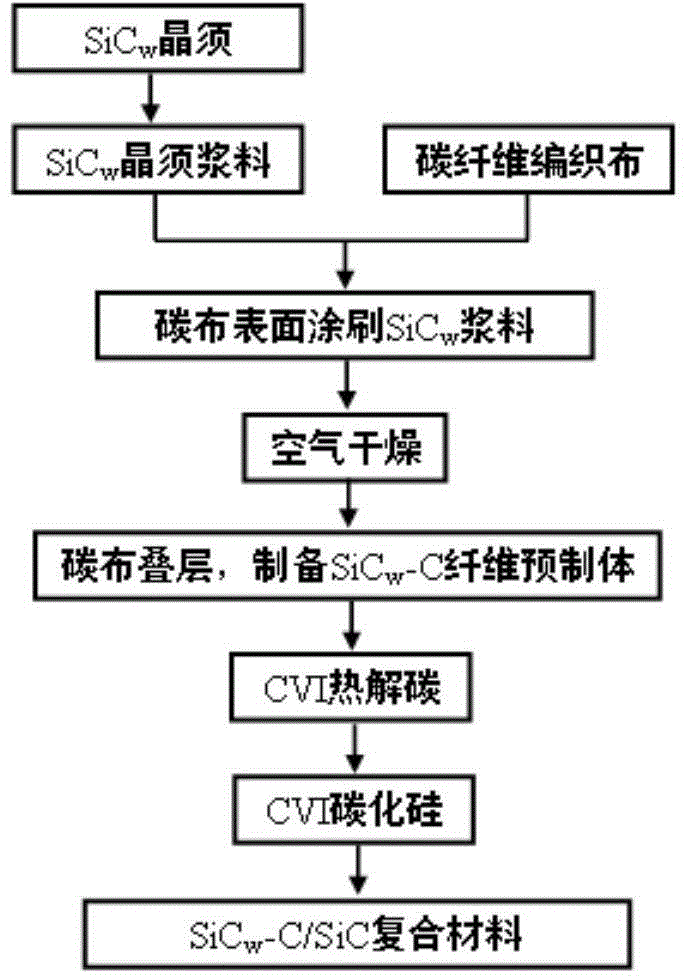

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: (1) SiC with an aspect ratio of 8 to 11 is used w Whiskers are used as a reinforcement, and the volume fraction is 20% alcohol as a solution, sonicated for 30 minutes, magnetically stirred for 2 hours, and dried;

[0025] (2) With isopropanol and toluene as solvent, SiC in step (1) w Whiskers are solutes, triethyl phosphate is used as a dispersant for ball milling for 10 hours, and the volume fraction of whiskers is controlled at 5%.

[0026] (3) Add polyvinyl butyral (PVB) as a binder and glycerol as a plasticizer to the slurry in step (2), and ball mill for 8 hours to obtain a stable SiC w slurry.

[0027] (4) Apply a layer of 5wt% SiC prepared in step (3) on 25 sheets of 2D[0° / 90°] carbon fiber cloth w Whisker slurry, dry naturally;

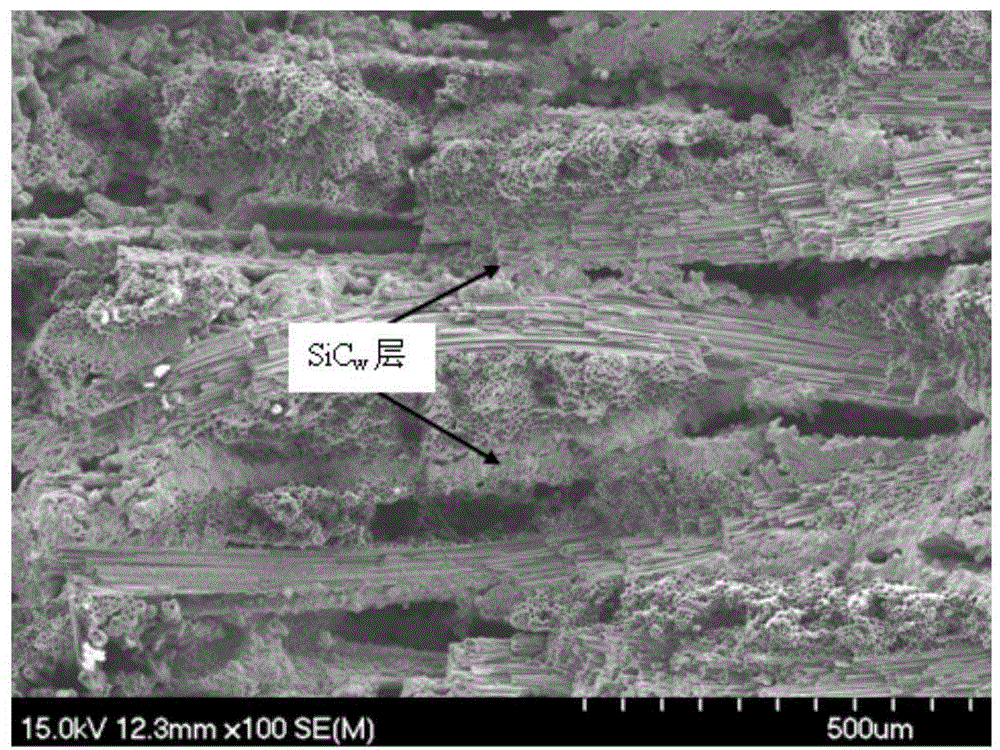

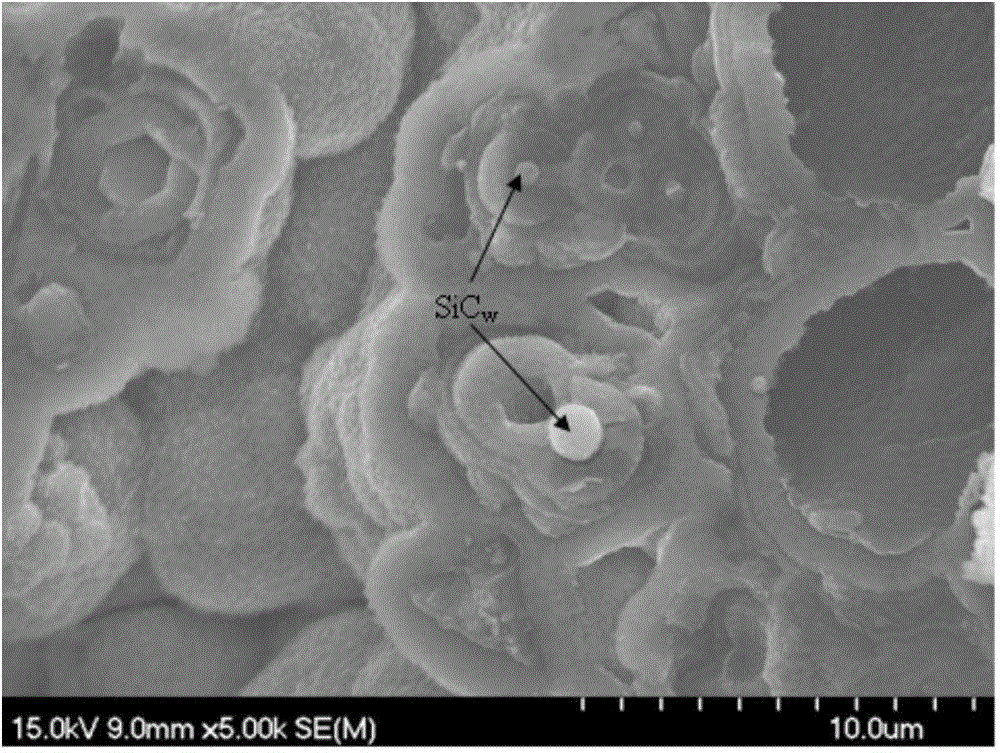

[0028] (5) with 5wt% SiC in step (4) w The 2D [0° / 90°] carbon fiber cloth of the whisker is stacked sequentially; from figure 2 SiC can be seen w Whisker layers and carbon cloth layers are alternately stacked.

[...

Embodiment 2

[0035] Embodiment 2: (1) SiC with an aspect ratio of 8 to 11 is used w Whiskers are used as a reinforcement, and the volume fraction is 20% alcohol as a solution, sonicated for 30 minutes, magnetically stirred for 2 hours, and dried;

[0036] (2) With isopropanol and toluene as solvent, SiC in step (1) w Whiskers are solutes, triethyl phosphate is used as a dispersant for ball milling for 10 hours, and the volume fraction of whiskers is controlled at 15%.

[0037] (3) Add polyvinyl butyral (PVB) as a binder and glycerol as a plasticizer to the slurry in step (2), and ball mill for 8 hours to obtain a stable SiC w slurry.

[0038](4) Apply a layer of 15wt% SiC prepared in step (3) on 25 sheets of 2D[0° / 90°] carbon fiber cloth w Whisker slurry, dry naturally;

[0039] (5) with 15wt% SiC in step (4) w The 2D [0° / 90°] carbon fiber cloth of the whiskers is stacked sequentially.

[0040] (6) Clamp the above-mentioned carbon fiber cloth stack with two porous shaped graphite tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com