Method for preparing graphene oxide/carbon nano tube/cellulose composite gel from ionic liquid

A carbon nanotube and ionic liquid technology, applied in the field of preparation of cellulose composite gel, can solve problems such as easy deformation of gel and solvent pollution, and achieve the effects of good stability, small solvent loss and excellent electrical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

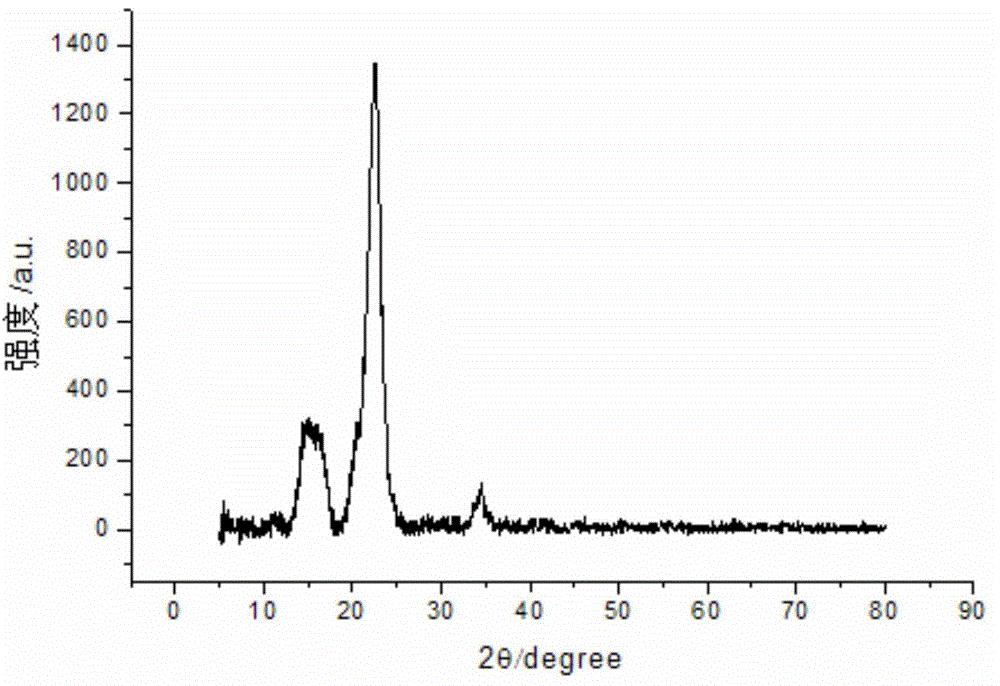

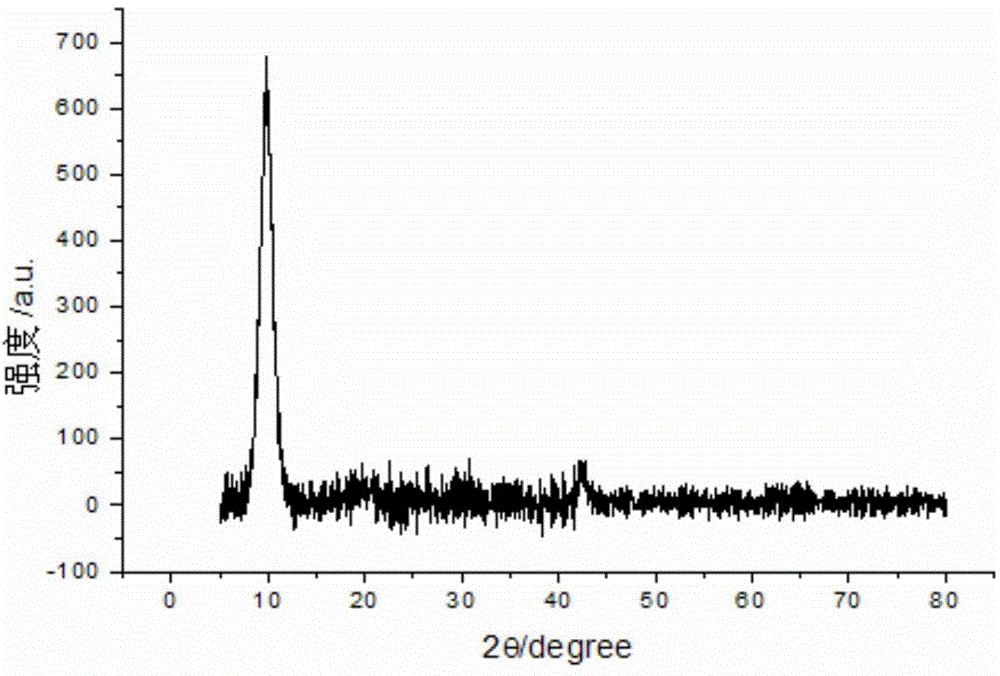

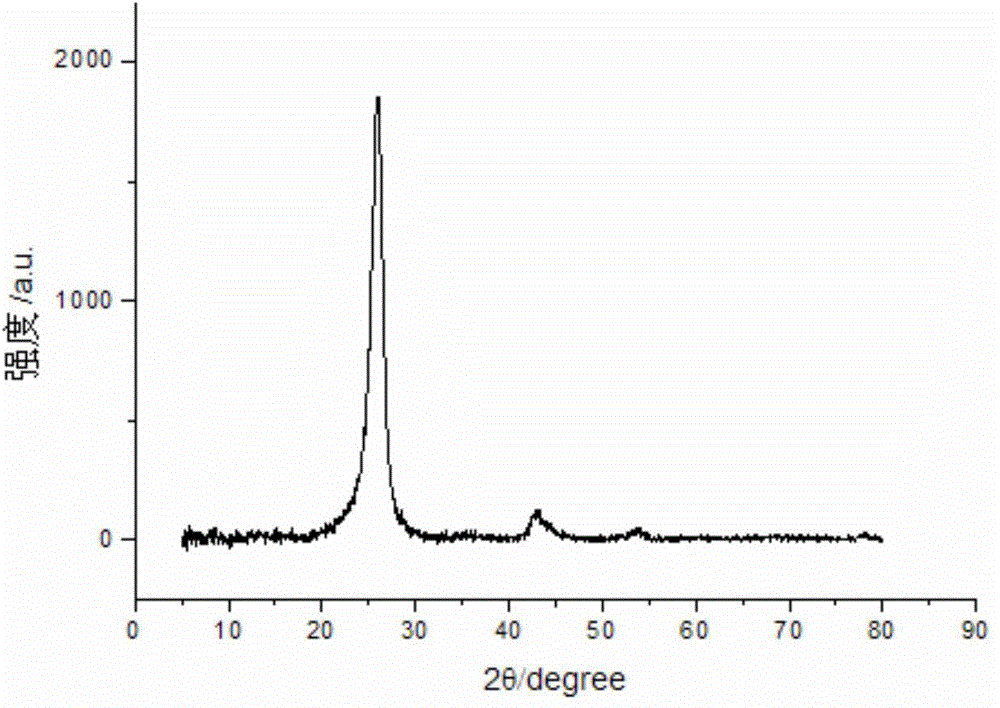

[0026] Specific embodiment one: the method for preparing graphene oxide / carbon nanotube / cellulose composite gel using ionic liquid in this embodiment is carried out according to the following steps:

[0027] 1. Weigh 0.5-10 parts by weight of cellulose and add it to 100 parts by weight of ionic liquid, stir and dissolve in an oil bath at 70-100°C for 8-12 hours to obtain a cellulose solution;

[0028] 2. Add graphene oxide and carbon nanotubes into the solvent respectively, and ultrasonically treat them to disperse them evenly, so as to obtain graphene oxide dispersion liquid and carbon nanotube dispersion liquid;

[0029] 3. Add the graphene oxide dispersion and the carbon nanotube dispersion to the cellulose solution prepared in step 1, and stir at 80-100°C for 12-24 hours to obtain a cellulose mixture;

[0030] 4. Pour the cellulose mixture obtained in step 3 into the mold, and after standing to cool down, immerse the mold together with the cellulose mixture in the deionize...

specific Embodiment approach 2

[0032] Embodiment 2: This embodiment is different from Embodiment 1 in that the cellulose described in step 1 is α-cellulose. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0033] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the ionic liquid described in step 1 is 1-butyl-3-methylimidazolium chloride. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com