High-wear-resistant and crack-resistant ceramic paint and preparation method thereof

A ceramic coating and anti-cracking technology, applied in the direction of coating, etc., can solve the problems of easy cracking of the coating film, poor wear resistance, affecting the long-term use of products, etc., and achieve the effect of good crack resistance and excellent wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

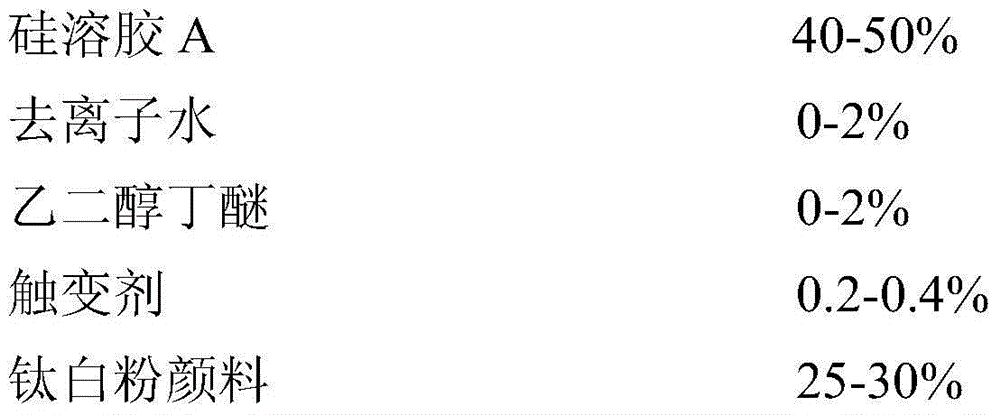

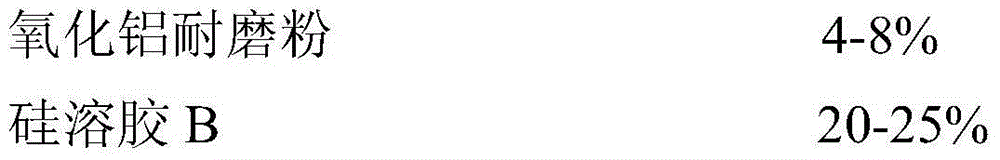

Method used

Image

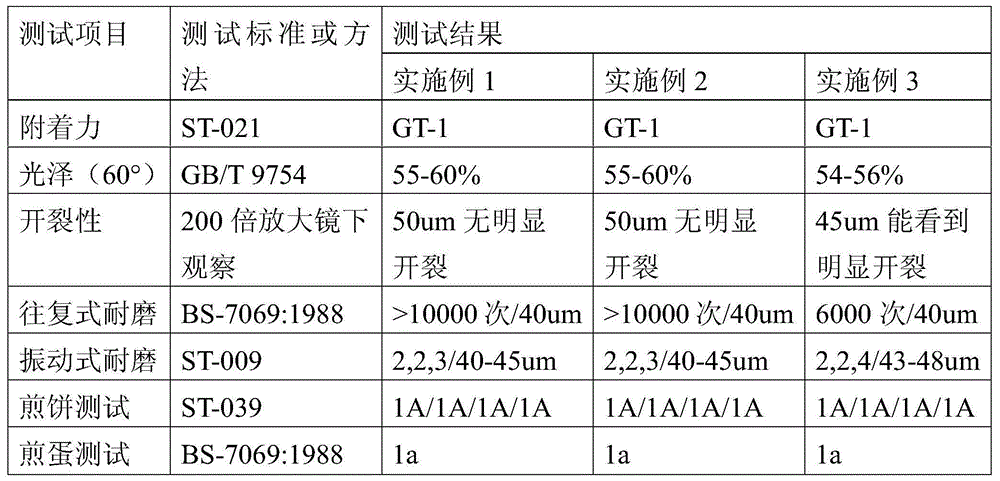

Examples

Embodiment 1

[0037] (1) Preparation of component A main agent:

[0038] ① First filter 530g of silica sol A with a 300-mesh nylon mesh and stir at a speed of 600r / min;

[0039] ②Add the mixture of 20g of deionized water and 22g of butyl glycol butyl ether that has been premixed uniformly to the silica sol A, and stir while adding;

[0040] ③Under stirring at 600r / min, add 3g of thixotropic agent to the mixture obtained in step ②, and disperse for 5 minutes at a speed of 800r / min;

[0041] ④ Under 600r / min stirring state, add 334g of titanium dioxide pigment and 78g of alumina wear-resistant powder to the mixture obtained in step ③, and disperse for 15 minutes at a speed of 1000r / min;

[0042] ⑤ Grind the mixture obtained in step ④ to a fineness of ≤15 μm with a basket sand machine, add 325 g of silica sol B under stirring at 600 r / min, and stir for 10 minutes to produce a finished product;

[0043] The viscosity of the component A is 12 seconds, measured with a DIN No. 4 cup at 23° C.; t...

Embodiment 2

[0051] (1) Preparation of component A main agent:

[0052] ① First filter 620g of silica sol A with a 300-mesh nylon mesh and stir at a speed of 700r / min;

[0053] ②Add the mixture of 25.4g deionized water and 25g butyl glycol butyl ether that has been premixed uniformly to the silica sol A, and stir while adding;

[0054] ③Under stirring at 700r / min, add 4g of thixotropic agent to the mixture obtained in step ②, and disperse at a speed of 1000r / min for 8 minutes;

[0055] ④Under stirring at 700r / min, add 360g of titanium dioxide pigment and 60g of alumina wear-resistant powder to the mixture obtained in step ③, and disperse for 20 minutes at a speed of 800r / min;

[0056] ⑤ Grind the mixture obtained in step ④ to a fineness ≤ 15 μm with a basket sand machine, add 280 g of silica sol B under stirring at 700 r / min, and stir for 5 minutes to produce a finished product;

[0057] The viscosity of the component A is 13 seconds, measured with a DIN No. 4 cup at 23° C.; the solid co...

Embodiment 3

[0065] (1) Preparation of component A main agent:

[0066] ① First filter 640g of silica sol A with a 300-mesh nylon mesh and stir at a speed of 800r / min;

[0067] ②Add the mixture of 26g of deionized water and 26g of butyl glycol butyl ether that has been premixed uniformly to the silica sol A, and stir while adding;

[0068] ③Under stirring at 800r / min, add 5g of thixotropic agent to the mixture obtained in step ②, and disperse at a speed of 1000r / min for 10 minutes;

[0069] ④Under stirring at 800r / min, add 380g of titanium dioxide pigment and 80g of alumina wear-resistant powder to the mixture obtained in step ③, and disperse for 18 minutes at a speed of 900r / min;

[0070] ⑤ Grind the mixture obtained in step ④ to a fineness of ≤15 μm with a basket sand machine, add 225 g of silica sol A under stirring at 800 r / min, and stir for 8 minutes to produce a finished product;

[0071] The viscosity of the component A is 14 seconds, measured with a DIN No. 4 cup at 23° C.; the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com