Subcritical extraction method capable of improving antioxidant activity of volatile oil in agarwood leaves

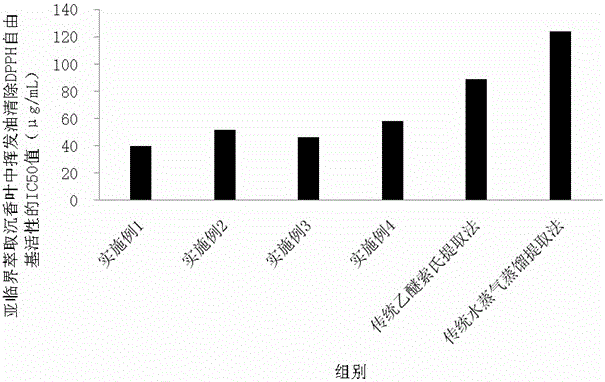

An oxidative activity, agarwood leaf technology, applied in the directions of essential oils/spices, fat generation, etc., can solve the problems of adverse effects of active substances, destruction of heat-sensitive components, low recovery rate, etc., achieves low scavenging activity, simplifies pretreatment steps, and recovers high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] (1) Clean, dry and remove the branches of Agarwood leaves, then place them in a vacuum drying oven at 45°C to dry to a moisture content of 8%, then adjust the temperature of the vacuum drying oven to 105°C and dry to constant weight, and crush to obtain 80 Purpose Agarwood leaf powder;

[0018] (2) Take the agarwood leaf powder from step (1) and put it in the extraction kettle, and after compacting it, put glass wool balls on the top of the extraction kettle to prevent the blown agarwood leaf powder from clogging the pipeline. According to the ratio of material to liquid (unit: g / mL) at a ratio of 1:60, add deionized water, carry out subcritical extraction for 14min under the extraction power of 3.0MPa, let stand to cool and carry out suction filtration, then repeat the extraction of the residue once, combine the two extracts, and then reduce Concentrate under pressure to obtain concentrated solution;

[0019] (3) After the concentrated solution obtained in step (2) is...

Embodiment 2

[0022] (1) Clean, dry and remove the branches of Agarwood leaves, then place them in a vacuum drying oven at 44°C to dry to a moisture content of 5%, then adjust the temperature of the vacuum drying oven to 106°C and dry to constant weight, crush to obtain 60 Purpose Agarwood leaf powder;

[0023] (2) Take the agarwood leaf powder from step (1) and put it in the extraction kettle, and after compacting it, put glass wool balls on the top of the extraction kettle to prevent the blown agarwood leaf powder from clogging the pipeline. According to the ratio of material to liquid (unit: g / mL) at a ratio of 1:40, add deionized water, carry out subcritical extraction for 10 min at an extraction power of 2.0 MPa, let stand to cool and then perform suction filtration, then repeat the extraction of the residue once, combine the two extracts, and then reduce Concentrate under pressure to obtain concentrated solution;

[0024] (3) After the concentrated solution obtained in step (2) is co...

Embodiment 3

[0027] (1) Clean, dry and remove the branches of Agarwood leaves, then put them in a vacuum drying oven and dry them at 46°C until the moisture content is 10%, then adjust the temperature of the vacuum drying oven to 104°C and dry them to a constant weight, and crush them to obtain 100 Purpose Agarwood leaf powder;

[0028] (2) Take the agarwood leaf powder from step (1) and put it in the extraction kettle, and after compacting it, put glass wool balls on the top of the extraction kettle to prevent the blown agarwood leaf powder from clogging the pipeline. According to the ratio of material to liquid (unit: g / mL) at a ratio of 1:80, add deionized water, carry out subcritical extraction for 18min under the extraction power of 4.0MPa, let stand to cool and carry out suction filtration, then repeat the extraction of the residue once, combine the two extracts, and then reduce Concentrate under pressure to obtain concentrated solution;

[0029] (3) After the concentrated solution ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com