Multifunctional polyamide 6 fiber and making method thereof

A manufacturing method and multi-functional technology, applied in fiber processing, rayon manufacturing, fiber chemical characteristics, etc., can solve problems such as increased production cost, insufficient anti-radiation effect, and increased sewage discharge.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

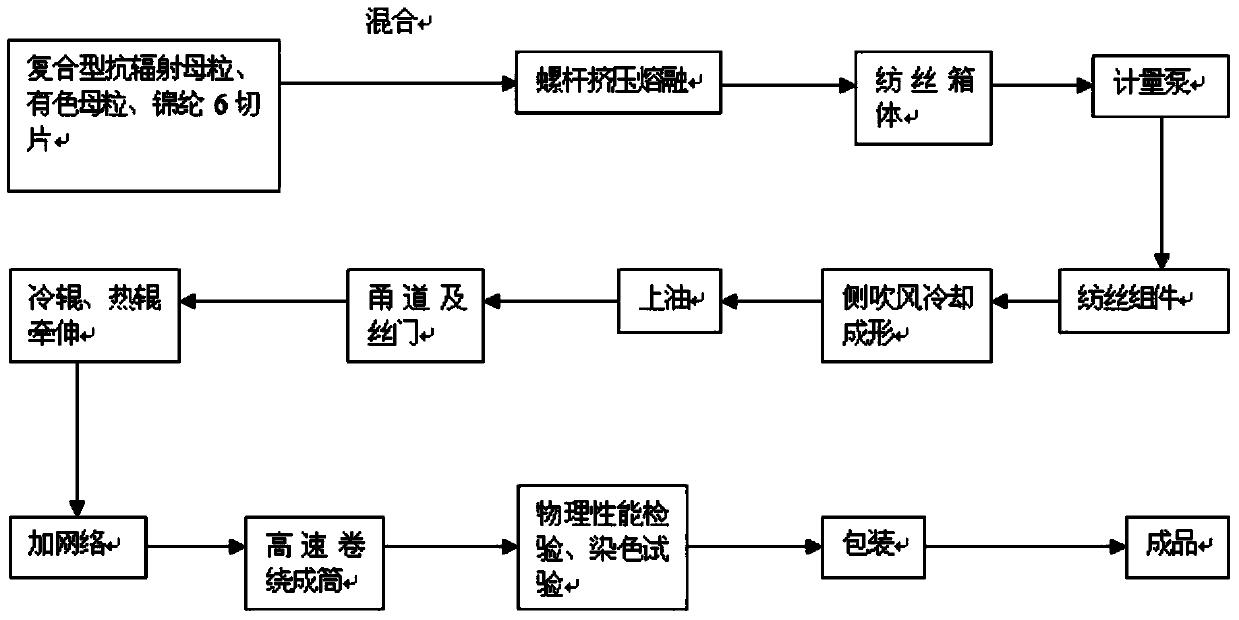

[0030] The dry composite anti-radiation masterbatch, black masterbatch and nylon 6 slices are evenly mixed, and added to a screw extruder for melt extrusion. The component composition of the above mixture is shown in Table 1 below. Among them, the composition of the composite anti-radiation masterbatch is shown in Table 2 below. Black masterbatch includes 40% pigment black components, 0.4% dispersant and 59.6% nylon 6 chips. The heating zone temperature and melt pressure of the screw extruder are shown in Table 3.

[0031] The fully melted melt is transported to the spinning box through a special melt pipeline. The temperature of the spinning box is 260°C, and the melt is extruded to the spinning assembly in a constant amount by the spinning metering pump for spinning. After the bundle is sprayed from the spinneret hole, it is cooled and formed by side blowing, the temperature of the side blowing is 17°C, and the humidity is 80%; then the cooled tow is oiled. In order to in...

Embodiment 2

[0034] Mix the dried composite anti-radiation masterbatch, gray masterbatch and nylon 6 slices evenly, and put them into a screw extruder for melt extrusion. The component composition of the above mixture is shown in Table 1 below. Among them, the composition of the composite anti-radiation masterbatch is shown in Table 2 below. Gray masterbatch includes 45% pigment ash component, 0.5% dispersant and 54.5% nylon 6 chips. The heating zone temperature and melt pressure of the screw extruder are shown in Table 3.

[0035] The fully melted melt is transported to the spinning box through a special melt pipeline. The temperature of the spinning box is 263 ° C. The melt is extruded to the spinning assembly in a constant amount by the spinning metering pump for spinning. After the tow is sprayed from the spinneret hole, it is cooled and formed by side blowing, the temperature of the side blowing is 18°C, and the humidity is 75%; then the cooled tow is oiled. In order to increase th...

Embodiment 3

[0038] The dry composite anti-radiation masterbatch, brown masterbatch and nylon 6 slices are evenly mixed, and added to a screw extruder for melt extrusion. The component composition of the above mixture is shown in Table 1 below. Among them, the composition of the composite anti-radiation masterbatch is shown in Table 2 below. Brown masterbatch includes 50% brown pigment components, 0.6% dispersant and 49.4% nylon 6 chips. The heating zone temperature and melt pressure of the screw extruder are shown in Table 3.

[0039] The fully melted melt is transported to the spinning box through a special melt pipeline, and the temperature of the spinning box is 265°C. The melt is extruded to the spinning assembly in a constant amount by the spinning metering pump for spinning. After the bundle is sprayed from the spinneret hole, it is cooled and formed by side blowing, the temperature of the side blowing is 18°C, and the humidity is 70%; then the cooled tow is oiled. In order to in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com