A high-efficiency and low-resistance air filter material preparation device

An air filter material and preparation device technology, which is applied in the fields of filtration and separation, complete sets of equipment for the production of artificial threads, non-woven fabrics, etc. The effect of injecting depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

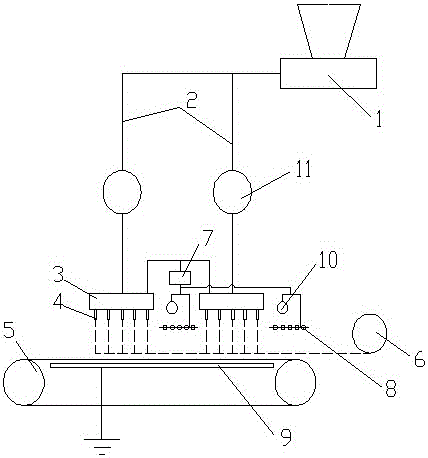

[0024] The high-efficiency and low-resistance air filter material preparation device of the present invention includes a fiber extruding device, a spinning device, a receiving net curtain device, a bias electrostatic charging device, and a winding device.

[0025] The fiber extruding device is an extruder 1, and the extruder 1 stores polyolefin polymer particles in a molten state, so as to be used as a raw material for preparing a fiber film. The spinning device is a spinning die 3 connected to the pipeline 2 of the extruder 1 , and a spinning hole 4 communicating with the pipeline 2 is arranged on the spinning die 3 . The web curtain receiving device is a conveyor belt 5 positioned directly below the spinneret die opening 3 , and the fiber film is placed on the conveyor belt 5 after the spinneret die mouth 3 ejects filaments and is formed. The bias electrostatic charging device comprises a bias electrode 10, a charge electrode 8 and a ground electrode 9, the bias electrode 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com