Cable fault detection and aging analysis method

A cable fault and aging analysis technology, applied in the direction of fault location, etc., can solve the problems of measurement accuracy impact, long sweep time, large fault location error, etc., and achieve the effect of reducing the volume of test equipment, saving test time, and accurate fault location

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

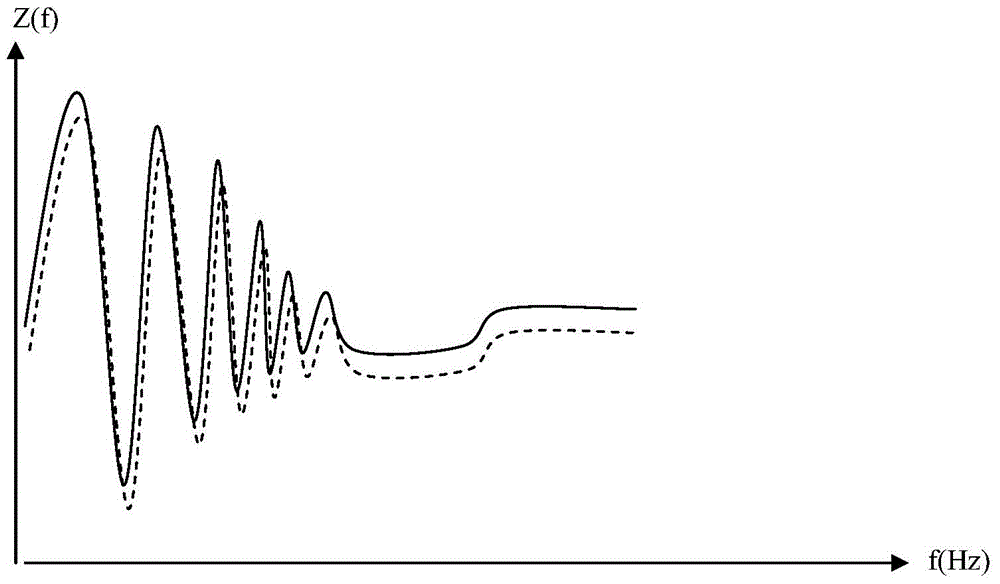

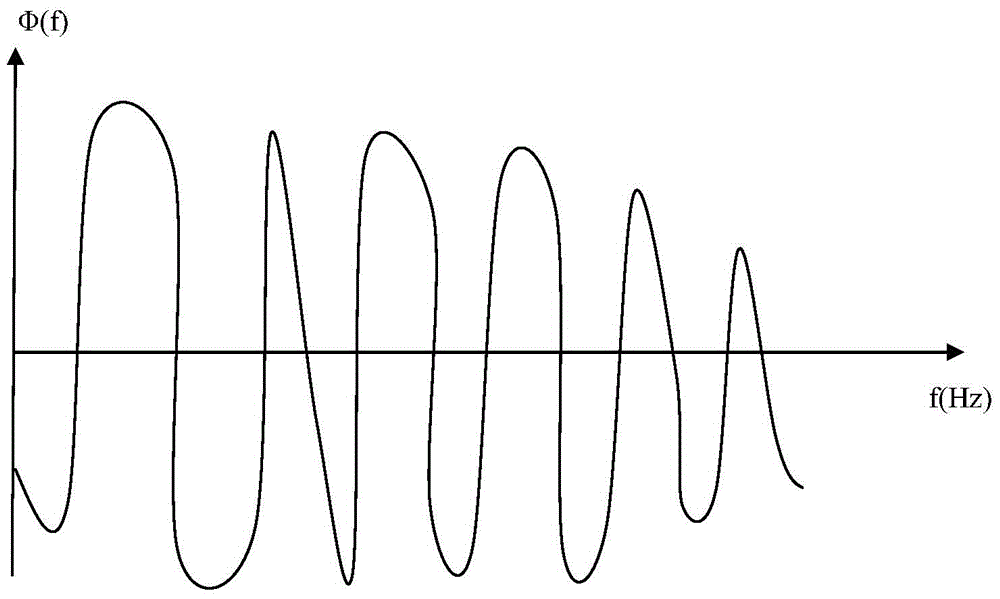

[0065] Such as figure 1 , figure 2 , image 3 shown. Fault detection and aging analysis for 220kV and XLPE cables include the following steps.

[0066] The first step is to apply a bandwidth of 0.1Hz-10kHz and a step frequency Δf between the insulated conductor and the shielding layer of the tested cable in the no-load state. k It is a 20Hz sweep signal, and then collect the voltage time domain signal corresponding to each sweep frequency input signal and the current time domain signal flowing through the cable to form a loop, and calculate the frequency domain impedance and phase of the cable, and draw the continuous impedance frequency curves and phase-frequency curves such as figure 1 , figure 2 shown.

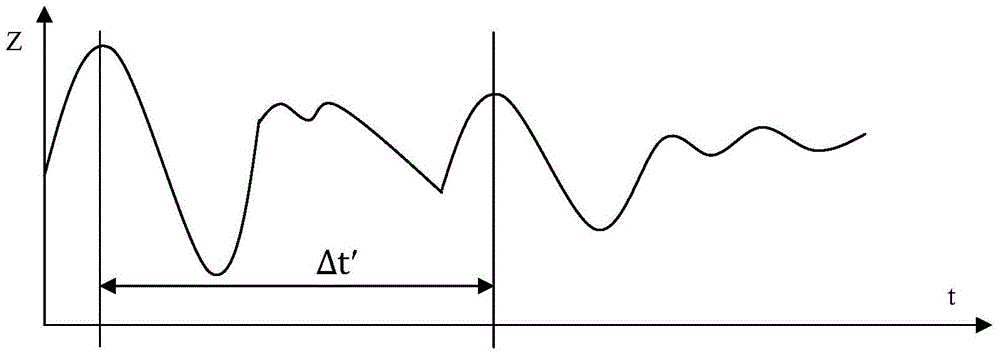

[0067] In the second step, on the impedance frequency curve drawn in the first step, find the first impedance peak value Z 0 is 400Ω, and its corresponding frequency f 0 The oscillation cut-off frequency f corresponding to the minimum impedance value of 320Hz and ...

Embodiment 2

[0081] Such as Figure 4 , Figure 5 shown. Fault detection and aging analysis for 220kV, XLPE cables with unknown length, including the following steps.

[0082] The first step is to apply a bandwidth of 100Hz-10kHz and a step frequency Δf between the multi-core cable conductors of the cable under load. k It is a 100Hz sweep signal, and then collect the voltage time domain signal corresponding to each sweep frequency input signal and the current time domain signal flowing through the cable to form a loop, and calculate the frequency domain impedance and phase of the cable, and draw the continuous impedance frequency curves and phase-frequency curves such as Figure 4 , Figure 5 shown.

[0083] In the second step, on the impedance frequency curve drawn in the first step, find the frequency f corresponding to the first impedance peak 0x The oscillation cut-off frequency f corresponding to the minimum impedance value of 206Hz and oscillation amplitude attenuation dx is 1...

Embodiment 3

[0099] The same parts as in Embodiment 2 will not be described again, the difference is that fault detection and aging analysis are performed on a 450kV cable with an unknown insulation type and a length of 10m. Pre-calculate the impedance-frequency curve of the cable, the initial sweep frequency point of the phase-frequency curve, the highest value of the sweep frequency, and the step value of the sweep frequency to optimize the test frequency band and improve test efficiency.

[0100] As stated earlier in this specification, the shorter the cable length, the higher the test frequency should be. First estimate the starting frequency range of the cable test, and set the transmission rate as half of the speed of light, that is, 150×10 6 m / s, then the characteristic frequency corresponding to the 10m far end of the cable is Assuming that the minimum detectable starting point (fault point and test terminal) distance is 0.1m, then the detected fault distance error is also 0.1m, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com