Method for preparing Cd1-xMnxSe quantum dot solar cell

A technology for solar cells and quantum dots, applied in the field of solar cells, can solve the problems of low efficiency of quantum dot solar cells, and achieve wide application prospects and research value, high efficiency, and the effects of improving absorption strength and absorption efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

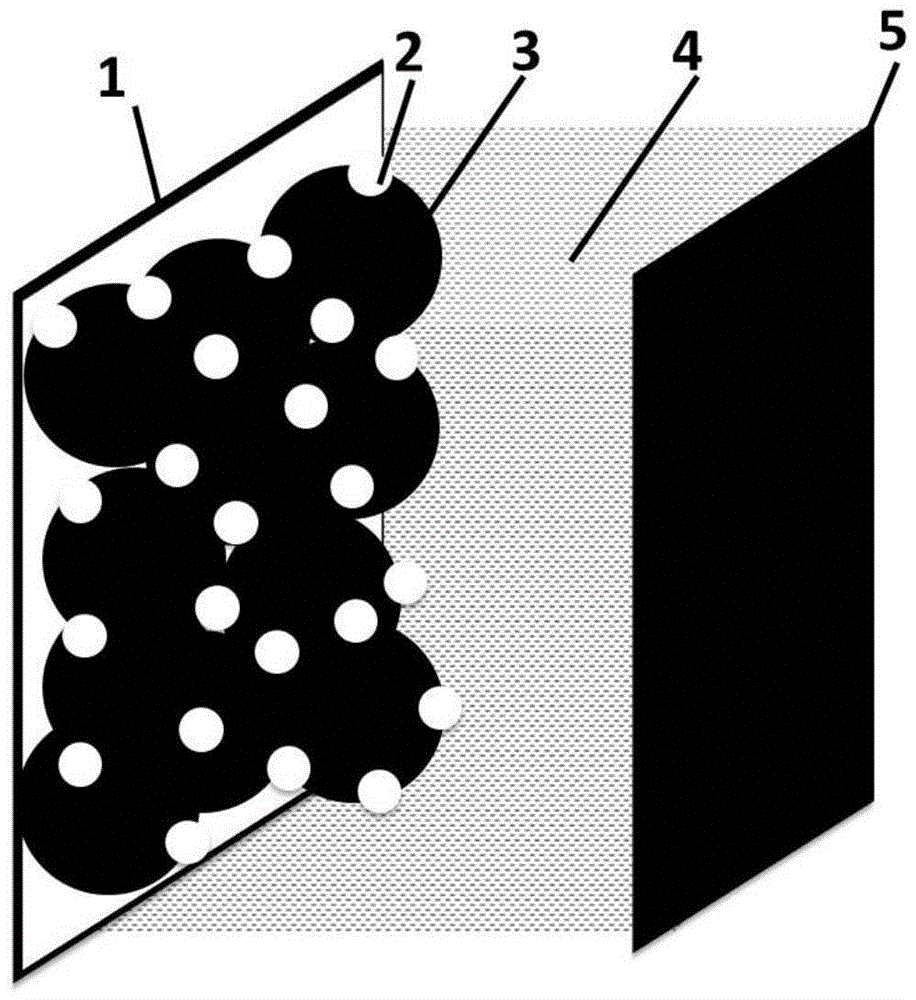

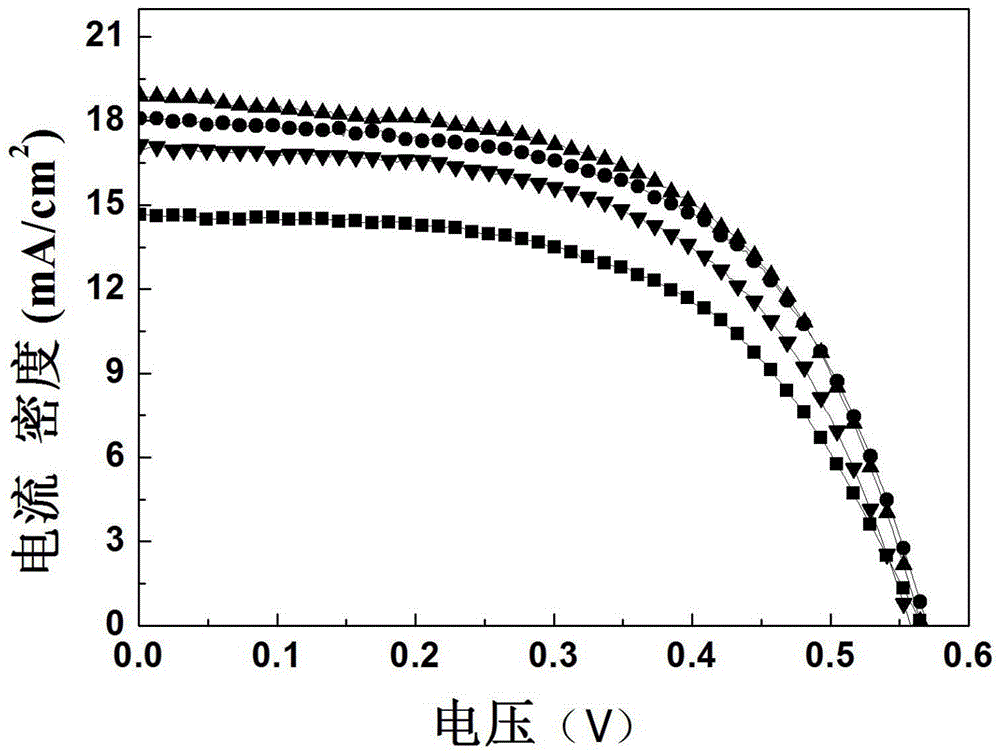

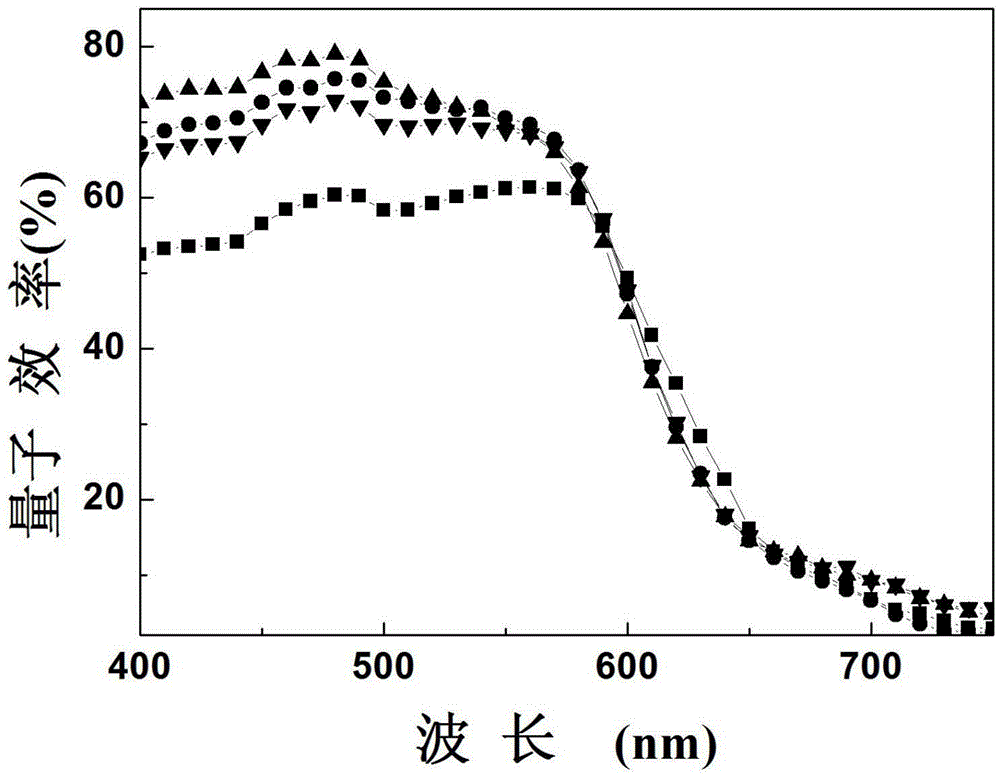

Embodiment 1

[0019] a) oxides with a particle size of 10-80nm (including TiO 2 , ZnO, SnO 2 or Zn 2 SnO 4 ) The powder and solvent are prepared into slurries of different concentrations; b) The above-mentioned slurries are evenly coated on the FTO or ITO glass substrate by the doctor blade method, and sintered at 300-500°C for 10-60min to obtain 4-20μm thick Nanoporous photoanode film; c) cadmium acetate (Cd(CH 3 COO) 2 2H 2 O) in deionized water, 0.1M manganese acetate (Mn(CH 3 COO) 2 4H 2 O) in deionized water, 0.1M sodium selenosulfate (Na 2 SeSO 3 ) in deionized water, 0.1M trisodium nitrilotriacetate (N(CH 2 COONa) 3 ) in a deionized aqueous solution; d) according to the volume ratio (1-x):x:1:2 (x=0.2) mixed evenly, configured as a reaction solution; e) vertically soak the photoanode in the reaction solution, avoid Quantum dots were adsorbed by chemical bath deposition under light conditions, the reaction temperature was 25°C, and the reaction time was 3.0h; f) Washed wit...

Embodiment 2

[0024] a) TiO with a particle size of 25nm 2 The powder and solvent are prepared into a slurry; b) the above slurry is evenly coated on the FTO glass substrate by the doctor blade method, and sintered at 500°C for 30 minutes to prepare a nanoporous photoanode film with a thickness of 10 μm; c) respectively arrange Cd 2+ source of deionized water, Mn 2+ Source of deionized water, sodium selenosulfate (Na 2 SeSO 3 ) in deionized aqueous solution, trisodium nitrilotriacetate (N(CH 2 COONa) 3 ) in a deionized aqueous solution with a concentration of 0.03-0.50M; d) mix uniformly according to the volume ratio (1-x):x:1:2 (x=0-0.8), and prepare a reaction solution; e) put the photoanode Immerse vertically in the reaction solution, absorb quantum dots by chemical bath deposition method under dark conditions, the reaction temperature is 5-40 °C, and the reaction time is 1-5h; f) Wash with deionized water and dry to obtain Cd 1-x mn x Se (x=0~0.8) photoanode of quantum dot solar c...

Embodiment 3

[0029] a) TiO with a particle size of 25nm 2 The powder and the solvent are prepared into a slurry; b) the above slurry is uniformly coated on the FTO glass substrate by the doctor blade method, and sintered at 500 ° C for 30 minutes to prepare a nanoporous photoanode film with a thickness of 10 μm; c) the concentration of each preparation is 0.1M cadmium acetate (Cd(CH 3 COO) 2 2H 2 O) in deionized water, 0.1M manganese acetate (Mn(CH 3 COO) 2 4H 2 O) in deionized water, 0.1M sodium selenosulfate (Na 2 SeSO 3 ) in deionized water, 0.1M trisodium nitrilotriacetate (N(CH 2 COONa) 3 ) in a deionized aqueous solution; d) according to the volume ratio (1-x):x:1:2 (x=0.2) mixed evenly, configured as a reaction solution; e) vertically soak the photoanode in the reaction solution, avoid Quantum dots were adsorbed by chemical bath deposition under light conditions, the reaction temperature was 25°C, and the reaction time was 3.0h; f) Washed with deionized water and dried to o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com