Novel enhanced Raman micro-needle with inbuilt enhanced layers and preparation method for novel enhanced Raman micro-needle

A Raman microneedle and reinforcement layer technology, which is applied in the field of enhanced Raman material preparation, can solve the problems of reducing Raman signal intensity, affecting the diffusion of tissue fluid, and weakening the enhancement effect of microneedles, so as to avoid attenuation and improve analysis sensitivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

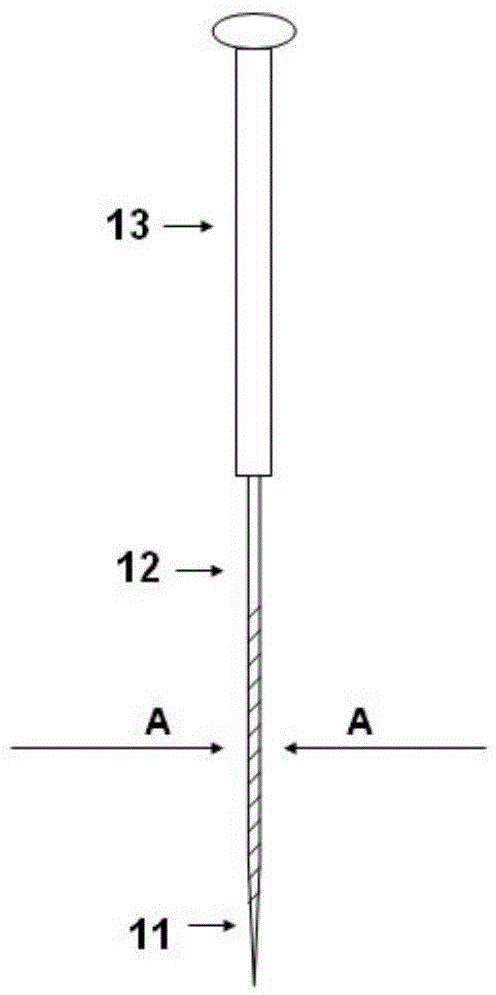

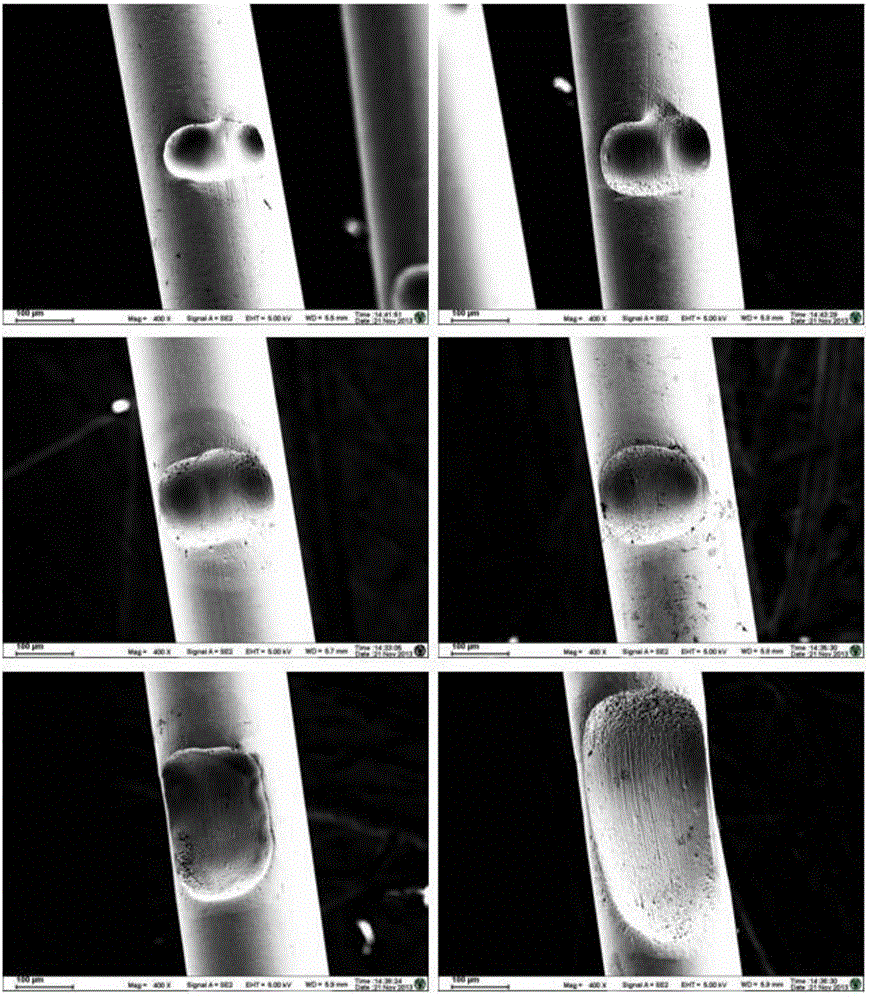

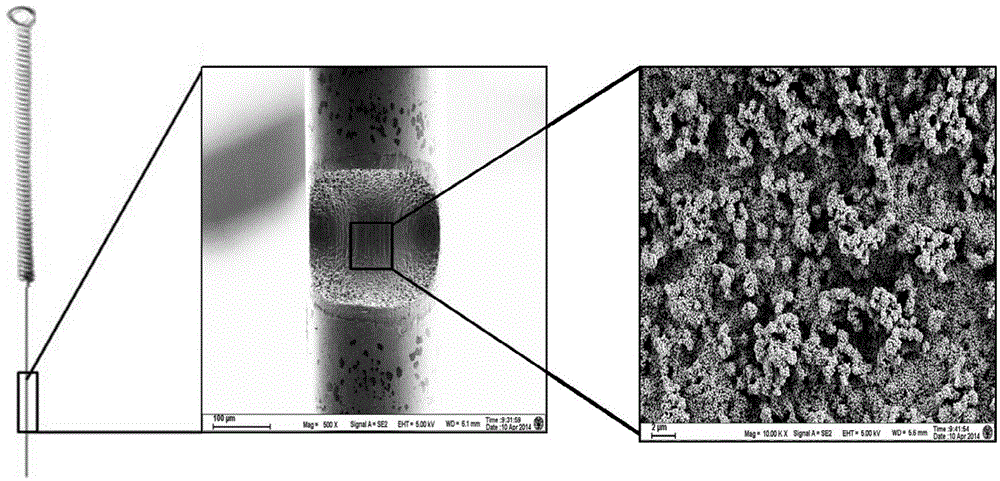

[0026] A new type of enhanced Raman microneedle with a built-in reinforcement layer. It includes a needle handle 13, a needle body 12 and a needle tip 11 connected in sequence from top to bottom. There is a group of micropores on the surface of the needle body 12 and needle tip 11. A metal nanomaterial layer is covered, and the metal nanomaterial layer is a composite nanolayer composed of a gold nanometer layer and a silver nanometer layer, and the thickness of the metal nanomaterial layer is 20 nanometers. Micropore diameter 20 microns, depth 5 microns.

[0027] The preparation method of the above-mentioned novel enhanced Raman microneedle built in the reinforcement layer comprises the following steps:

[0028] 1) Insert the needle body and needle tip of the microneedle into the polymer solution and let it stand for 30 seconds to obtain a polymer layer. The polymer mass and solvent volume ratio in the polymer solution is 0.1%, and the polymer layer is is polystyrene;

[002...

Embodiment 2

[0033] A new type of enhanced Raman microneedle with a built-in reinforcement layer. It includes a needle handle 13, a needle body 12 and a needle tip 11 connected in sequence from top to bottom. There is a group of micropores on the surface of the needle body 12 and needle tip 11. A metal nanomaterial layer is covered, and the metal nanomaterial layer is one or more of gold nanolayer, silver nanolayer, copper nanolayer or platinum nanolayer, and the thickness of the metal nanomaterial layer is 2500 nanometers. The micropores are 5 microns in diameter and 25 microns in depth.

[0034] The preparation method of the above-mentioned novel enhanced Raman microneedle built in the reinforcement layer comprises the following steps:

[0035] 1) Insert the needle body and needle tip of the microneedle into the polymer solution and let it stand for 1 second to obtain a polymer layer. The polymer mass and solvent volume ratio in the polymer solution is 10%, and the polymer layer is It i...

Embodiment 3

[0040] A new type of enhanced Raman microneedle with a built-in reinforcement layer. It includes a needle handle 13, a needle body 12 and a needle tip 11 connected in sequence from top to bottom. There is a group of micropores on the surface of the needle body 12 and needle tip 11. A metal nanomaterial layer is covered, and the metal nanomaterial layer is one or more of gold nanolayer, silver nanolayer, copper nanolayer or platinum nanolayer, and the thickness of the metal nanomaterial layer is 1260 nanometers. The diameter of the micropore is 50 microns, and the depth is 50 microns.

[0041] The preparation method of the above-mentioned novel enhanced Raman microneedle built in the reinforcement layer comprises the following steps:

[0042] 1) Insert the needle body and needle tip of the microneedle into the polymer solution and let it stand for 60 seconds to obtain a polymer layer. The polymer mass and solvent volume ratio in the polymer solution is 5%, and the polymer layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com