π-type phthalocyanine pigment, method for producing same, pigment composition, coloring composition, and color filter

A technology for coloring composition and manufacturing method, which is applied in the direction of optical filters, chemical instruments and methods, azo dyes, etc., can solve the problems of easy crystallization transfer, poor stability, and low stability, and achieve color characteristics and stability Excellent, excellent display quality effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

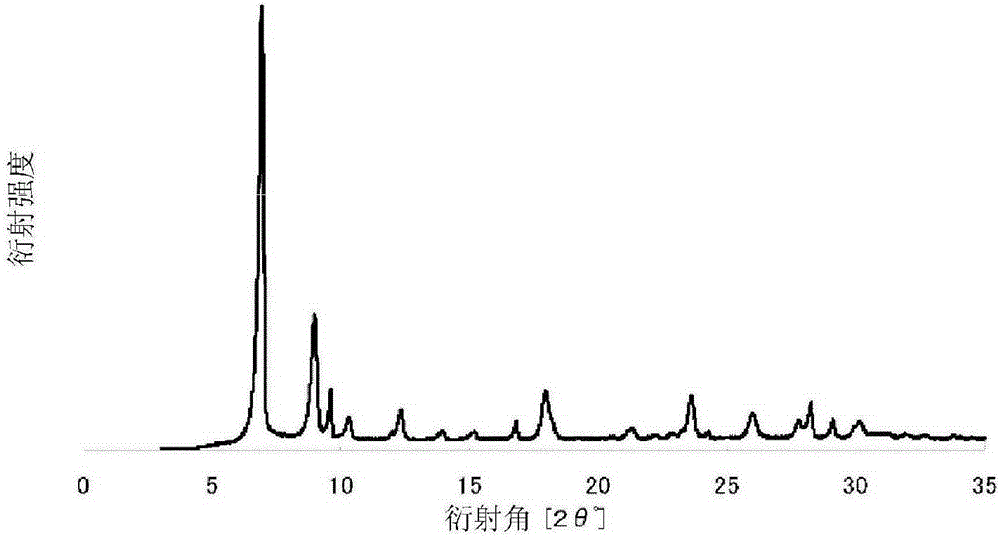

[0236] A π-type copper phthalocyanine pigment was produced by the Wheeler method using the following raw materials.

[0237]

[0238]

[0239] Each raw material was put into the synthesis apparatus, and it maintained at 180 degreeC for 5 hours, stirring, and the copper phthalocyanine pigment was produced|generated by this. The obtained reaction solution containing the copper phthalocyanine pigment was filtered under reduced pressure while being washed with 60° C. warm water, and the solvent, unreacted products, and the like were removed from the reaction solution.

[0240] The crude pigment from which the solvent and the like have been removed is subjected to filtration and purification as follows. First, the crude pigment was added to 500 parts of 3% sulfuric acid heated at 80° C., stirred for 30 minutes, and then filtered under reduced pressure while washing with 60° C. warm water. Next, after adding to 500 parts of 3% sodium hydroxide heated at 80 degreeC and stirrin...

Embodiment 2~ Embodiment 27

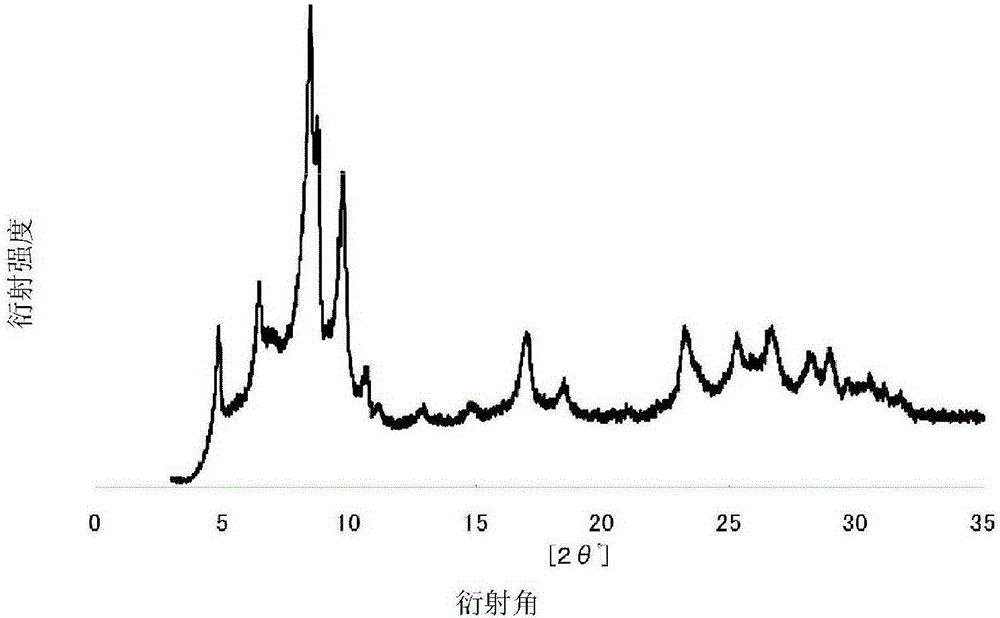

[0249] Carry out in the same manner as in Example 1, change the solvent type, the catalyst type, the phthalic acid (phthalic acid derivative) type, synthesis temperature, and phthalic anhydride input amount that are substituted at the alpha position as shown in Table 1 , α-position substituted phthalic acid input amount and solvent amount, synthesized by the same operation, thereby making the π-type copper phthalocyanine pigment 2-π-type copper phthalocyanine of Examples 2-27 Pigment 27. It was confirmed by powder X-ray diffraction that these crystal forms were all π-type.

[0250] Similarly, the pigment composition 2 - the pigment composition 27 and the coloring composition 2 - the coloring composition 27 were produced using the π-type copper phthalocyanine pigment 2 - the π-type copper phthalocyanine pigment 27.

[0251] [Table 1]

[0252]

Embodiment 28

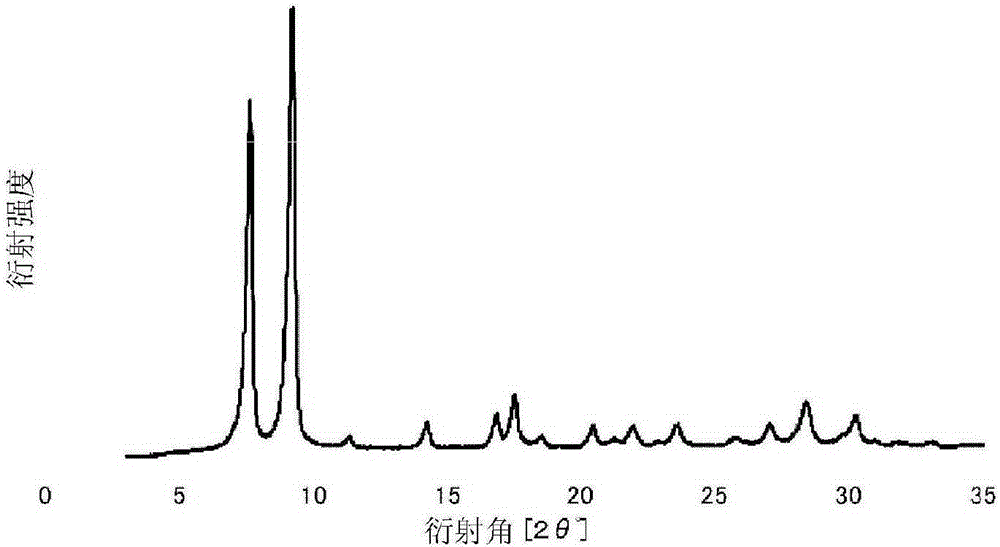

[0254] A π-type copper phthalocyanine pigment was produced by the phthalonitrile method using the following raw materials.

[0255]

[0256] Each raw material was put into the synthesis apparatus, and after heating up to 130 degreeC, stirring, 15.2 parts of diazabicycloundecenes were added and maintained for 3 hours, and the copper phthalocyanine pigment 28 was produced. Furthermore, filtration purification, dispersion, and stirring and mixing after synthesis were performed in the same manner as in Example 1 to prepare the pigment composition 28 and the coloring composition 28 . The obtained crystal form was π form.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com