Sheet metal oxide catalyst and preparation method thereof

A flake metal and catalyst technology, which is applied in the field of flake metal oxide catalysts and their preparation, can solve the problems of complicated process, reduced activity and stability, and reduced effective components of catalysts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] For the preparation of catalyst 1, 100 g of magnesium oxide was modified with 500 g of oxalic acid solution with a mass concentration of 2%, and stirred at 60° C. for 8 hours. Obtain filter cake after filtering, at 120 o C and dried for 8 hours. After the sample is dried, it is powdered. Thereafter, use a spray dryer, granulator, extruder or tablet machine to granulate, dry, and take 10-60 mesh granules for use. Add 5% magnesium stearate of total mass as a release agent, and mix homogeneously with the above-mentioned manufactured granules. 10g of water was added dropwise, and after being fully mixed, it was added to the feed port of a tablet machine for tablet molding to obtain a catalyst precursor. After 120 oC Dry for 8 hours, thereafter at 560 oC Calcined for 6 hours to prepare a molded sample catalyst.

Embodiment 2~18

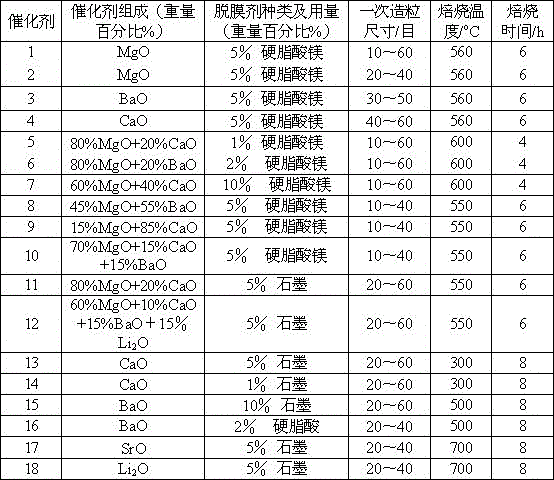

[0040] Corresponding to Catalysts 2-18, the catalysts were prepared according to the steps in Example 1, except that the composition and preparation conditions of the catalysts were changed. The preparation conditions and composition of the catalysts are shown in Table 1.

[0041] Table 1

[0042]

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com