Curved-surface molybdenum disulfide nanosheet and preparation method thereof

A molybdenum disulfide and nanosheet technology, applied in the direction of molybdenum sulfide, nanotechnology for material and surface science, nanotechnology, etc., can solve the problems of complex preparation process, low efficiency, and difficulty in mass production, and achieve macro-quantification. simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

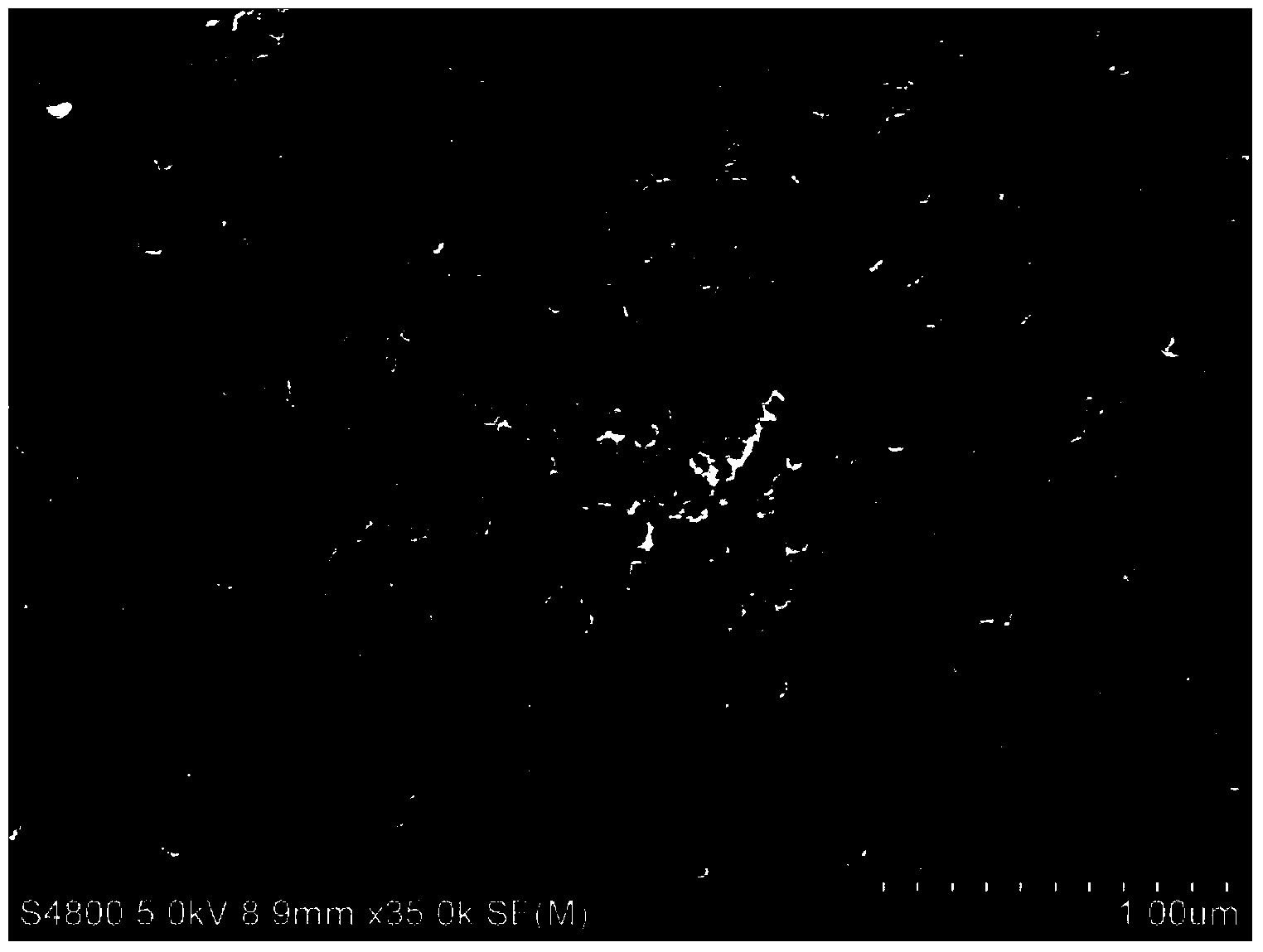

[0020] Weigh 0.06 g of sodium molybdate and 0.24 g of thioacetamide respectively, dissolve them in a mixed solution of 40 ml of deionized water and N-methylpyrrolidone with a volume ratio of 1:4, and transfer them to 50 ml of in a polytetrafluoro container and fixed in a stainless steel reaction kettle (polytetrafluoro container, to avoid the use of metal ions in metal containers to participate in the reaction to cause pollution), and then directly heated in an oven at 200 degrees for 12 hours, until the reaction kettle When the temperature naturally drops to 25 degrees, the obtained reactant is washed three times with water and ethanol respectively, and the washed sample is dried in a 60 degree oven for 4 hours. figure 1 Scanning electron micrograph of the curved molybdenum disulfide nanosheets prepared in Example 1. Depend on figure 1 It can be seen that the molybdenum disulfide nanosheets have a diameter of about 100 nanometers and are curved.

Embodiment 2

[0022] Weigh 0.3 g of sodium molybdate and 1.2 g of thioacetamide respectively, dissolve them in a mixed solution of 40 ml of deionized water and N-methylpyrrolidone with a volume ratio of 1:4, and transfer them to 50 ml of In a polytetrafluoro container and fixed in a stainless steel reaction kettle, and then directly heated in an oven at 200 degrees for 12 hours, when the temperature of the reaction kettle is naturally lowered to 30 degrees, the obtained reactants were respectively watered and ethanol sequentially After washing 3 times, the washed sample was dried in a 60-degree oven for 4 hours to obtain curved molybdenum disulfide nanosheets.

Embodiment 3

[0024] Weigh 0.06 g of sodium molybdate and 0.48 g of thioacetamide respectively, dissolve them in a mixed solution of 40 ml of deionized water and N-methylpyrrolidone with a volume ratio of 4:1, and transfer to 50 ml of In a polytetrafluoro container and fixed in a stainless steel reaction kettle, and then directly heated in an oven at 200 degrees for 12 hours, when the temperature of the reaction kettle is naturally lowered to 26 degrees, the obtained reactants were respectively watered and ethanol sequentially After washing 3 times, the washed sample was dried in a 60-degree oven for 4 hours to obtain curved molybdenum disulfide nanosheets.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com